ABB 1MRB150083R1F / 216EA62 – Servo Motor Feedback Assembly for Precise Motion on IRB and ACS-driven Axes

The 1MRB150083R1F paired with 216EA62 is commonly supplied as an ABB motor-mounted feedback/encoder assembly, used to deliver accurate position feedback to ACS-series drives and IRB robot axes. From my experience, this unit is typically a drop-in replacement for selected ABB servo motor frames, helping maintenance teams restore positioning accuracy without re-engineering the system.

You might notice that sites running pick-and-place, arc welding, or palletizing cells keep a spare of this model on hand. The reason is simple: fast swap, consistent encoder alignment, and predictable compatibility with ABB motion control.

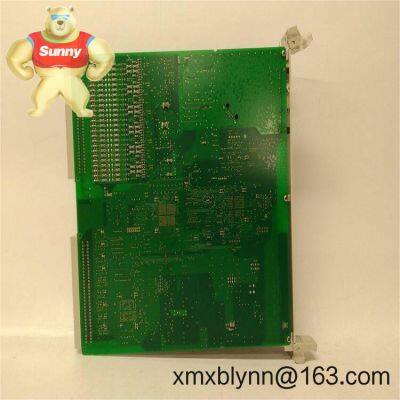

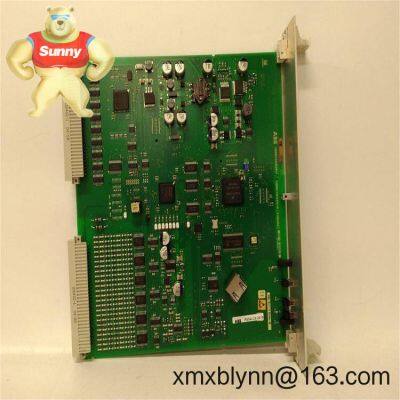

Form-fit-function replacement – 1MRB150083R1F (assembly) with 216EA62 (feedback element) is designed to mount on specific ABB motor frames with no machining.

High-resolution feedback – Supports smooth velocity control and tight path accuracy; in many cases this directly improves cycle-to-cycle repeatability.

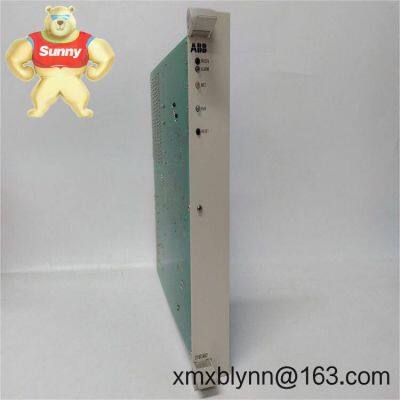

Signal compatibility – Typically resolver or incremental differential (A/B/Z) feedback for ABB ACS/DSQC control—confirm signal type before ordering.

Industrial build – Robust housing and sealed connectors help the unit tolerate dust, oil mist, and vibration common in robot bases and machine frames.

Fast turnaround maintenance – Factory indexed components reduce alignment time; technicians can usually replace and re-reference the axis during a short stop.

Traceable part coding – Clear model and revision labeling assist with BOM matching across IRB families and motor variants.

| Parameter | Details |

|---|---|

| Brand / Model | ABB – 1MRB150083R1F (assembly), 216EA62 (feedback element) |

| Power Requirements | Varies by variant; typically 5 VDC for incremental encoders or ~7 VRMS, 10 kHz for resolver-type feedback |

| Signal Input/Output | Differential A/B/Z (TTL/RS-422) or resolver sin/cos; confirm against your drive/DSQC module |

| Operating Temperature | Typically −20 to +85 °C (installation and motor frame dependent) |

| Ingress Protection | Up to IP54–IP65 when correctly mounted and sealed on the motor endbell |

| Communication Interfaces | Direct feedback wiring to ABB drive/controller (non-fieldbus) |

| Installation Method | Motor-mounted encoder/resolver kit; keyed flange and indexed coupling for rapid alignment |

| Dimensions & Weight | Frame-dependent; compact low-profile assembly suited to ABB servo endbells |

This model appears most frequently in ABB robotics and motion applications where precision and uptime matter. Typical deployments include:

IRB robot axes for material handling, palletizing, and machine tending

Automotive body-in-white fixtures and spot/arc welding cells

Packaging and pallet cell conveyors driven by ABB ACS controllers

General-purpose servo retrofits where ABB motors are retained

Feedback from a packaging customer: “Swapping the 1MRB…R1F kit with the 216EA62 head cut our changeover time to under 30 minutes, and the axis tuned cleanly on the first pass.”

Risk reduction – Matching the ABB-coded model typically avoids pinout surprises and re-qualification on safety-rated cells.

Shorter downtime – Pre-aligned hardware and familiar connectors help maintenance return a line to service quickly.

Lifecycle compatibility – Works with established ABB drives and DSQC feedback modules, a practical choice for brownfield sites.

Total cost – Fewer engineering hours and no mechanical rework often outweigh the unit price, especially in multi-robot plants.

Technical support – Documentation and parameter references are widely available for ABB service personnel.

Environment – Mount in a clean, dry area of the motor endbell; ensure cabinet wiring uses shielded twisted pairs with proper drain/earth bonding.

Alignment – Use the motor’s alignment marks/indexing tool; avoid forcing the coupling. Incorrect phasing can cause drive faults or oscillation.

Ventilation – Keep the motor area free of built-up oil/dust; heat soak can affect sensor stability in extreme cases.

Wiring – Route feedback cables away from VFD motor leads; maintain separation and use ferrules on terminal blocks to prevent whiskers.

Safety – Lockout/tagout the drive, discharge DC bus, and follow ESD precautions when handling the feedback element.

Routine checks – Inspect connector seals and cable strain relief quarterly; verify encoder counts per rev and direction during scheduled calibration.

Firmware and tuning – After replacement, run the drive’s identification/tuning routine and confirm resolver/encoder parameters match the motor nameplate.

CE and RoHS compliance typical for ABB feedback components

Manufactured under ISO 9001 quality systems

UL recognition may apply to associated assemblies; check your exact revision code

Standard manufacturer warranty (commonly 12 months) against defects when installed per guidelines

Send Inquiry to This Supplier

You May Also Like

-

ABB 83SR04C-E (GJR2390200R1411) – Relay Output Module for Procontrol P14 SystemsNegotiableMOQ: 1 Combo

-

ABB HIEE305098R0001 – Plug‑in DCS Module for Legacy System Expansion and Reliable SparesNegotiableMOQ: 1 Combo

-

ABB 5SHY35L4522 IGCT Gate Unit – Trusted Drive Control for High‑power ConvertersNegotiableMOQ: 1 Combo

-

ABB 07AI91 (GJR5251600R4202) – Analog Input Module for AC31/CS31 Process ControlNegotiableMOQ: 1 Combo

-

ABB 07BR61R1 (GJV3074376R1) – MasterBus 300 Repeater for Segment Isolation and Distance ExtensionNegotiableMOQ: 1 Combo

-

ABB 07DC91 (GJR5251400R0202) – Digital Control/communication Module for Legacy Procontrol/Advant 07-series SystemsNegotiableMOQ: 1 Combo

-

ABB 07EA90-SI (GJR5251200R0101) – System Interface Module for Advant Master S100 I/ONegotiableMOQ: 1 Combo

-

ABB 07KT94 (GJR5252100R3261) – Communication/Processor Module for Advant Controller 31 (AC31) SystemsNegotiableMOQ: 1 Combo

-

ABB 086318-002 / 086318-501 – Legacy I/O Termination Assembly for ABB Bailey INFI 90 / NET 90 CabinetsNegotiableMOQ: 1 Combo

-

ABB 086329-004 – Legacy DCS Module for ABB Bailey INFI 90 Maintenance and SparesNegotiableMOQ: 1 Combo