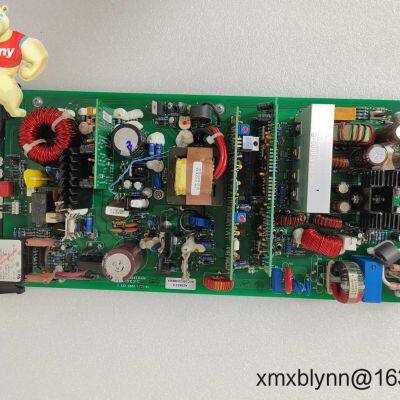

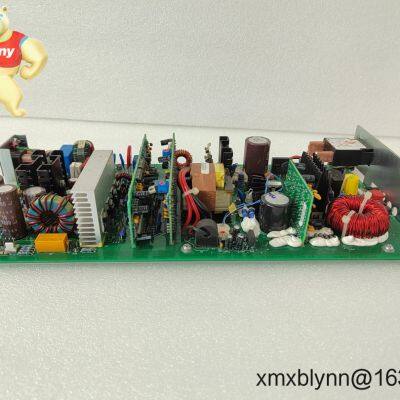

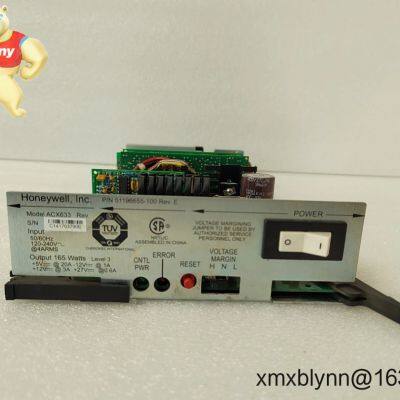

HONEYWELL 51196655-100 – Legacy DCS Board Assembly for TPS/TDC Systems

The HONEYWELL 51196655-100 is a field-proven spare/board assembly used in legacy Honeywell TPS/TDC 3000 control systems. It’s typically applied as a plug-in module within the controller or I/O subsystem, helping plants keep their installed base stable without a full platform upgrade.

From my experience, plants choose this part when they need like-for-like replacement to minimize downtime and avoid re-engineering. It seems to be favored in brownfield maintenance programs where continuity and interchangeability matter more than new features.

Drop-in compatibility – Designed to fit the original Honeywell rack/backplane so you can swap modules without panel redesign.

Stable lifecycle support – Commonly used in long-running TPS/TDC 3000 systems; supports continuity of operations in critical units.

Backplane-powered – Draws power from the system backplane; no external power wiring in most cases.

Serviceable design – Supports standard ESD-safe handling practices and slot-level replacement to shorten turnaround during outages.

Proven reliability – These boards were engineered for 24/7 industrial environments where predictable behavior matters.

| Brand / Model | HONEYWELL 51196655-100 |

| Power Requirements | Backplane-supplied (no separate external supply; typical logic rails provided by Honeywell chassis) |

| Operating Temperature | 0 to 50°C typical for cabinet-installed electronics (non-condensing) |

| Signal I/O Types | Via system backplane; field terminations and I/O specifics depend on the associated Honeywell subsystem |

| Communication Interfaces | Backplane bus interface (no front-mounted network ports) |

| Installation Method | Plug-in card; mounts into the Honeywell rack/chassis slot per system documentation |

You’ll typically find the 51196655-100 in plants running Honeywell TPS/TDC 3000—including continuous processes that can’t tolerate unexpected changes. It’s especially common where standardized spares are kept for quick swap-outs.

Oil & Gas (upstream treating units, midstream compression, downstream refining)

Petrochemicals & Chemicals (reactors, distillation, utilities)

Power Generation (balance-of-plant, legacy turbine auxiliaries)

Pulp & Paper, Metals, and other heavy industries maintaining TPS/TDC installations

Lower risk vs. platform migration – Keeps the installed software/database and wiring intact, reducing commissioning effort.

Predictable downtime – Slot-for-slot replacement means faster turnaround during planned outages and corrective maintenance.

Compatibility – Engineered for the Honeywell backplane, helping avoid quirky incompatibilities seen with ad-hoc substitutions.

Cost control – In many cases, a board-level replacement defers a larger capex project, spreading costs across the asset lifecycle.

“We swapped the 51196655-100 during a 6‑hour maintenance window and were back online without touching our I/O assignments.” — Maintenance Supervisor, petrochemical site

Cabinet & environment – Install in a clean, enclosed control cabinet compliant with Honeywell’s rack specs; provide ventilation to keep internal air within 0–50°C and non-condensing humidity.

Handling – Use ESD protection (wrist strap, antistatic mat). De-energize the rack or follow hot-swap guidance only if explicitly allowed by your system manual.

Wiring – Field terminations stay on terminal assemblies; verify backplane connectors are clean, firmly seated, and free of bent pins.

Commissioning – After replacement, run the controller diagnostics and confirm module health in the system console; monitor for several process cycles.

Routine care – Periodically inspect for dust and oxidation; schedule firmware/configuration alignment if your site manages module revisions at the database level.

Certifications – Honeywell TPS/TDC system components are typically supplied with CE and UL compliance at the system level; specific board markings may vary by production lot and region.

Quality – Manufactured under Honeywell’s industrial quality system; parts are traceable by part and revision code.

Warranty – Standard 12-month repair/replace warranty is common for new or refurbished spares, subject to terms at time of sale.

Send Inquiry to This Supplier

You May Also Like

-

Honeywell CC‑PCF901 51405047‑176 — Process Control Function / I/O ModuleNegotiableMOQ: 1 Combo

-

Honeywell CC-PAIX02 (51405038-476) — I/O & Interface Expansion Module for Control CabinetsNegotiableMOQ: 1 Combo

-

Honeywell CC-PWRR01 51199929-100 — Redundant Power Module for CC ControllersNegotiableMOQ: 1 Combo

-

Honeywell CC-PCNT02 + DC-TCNT01 — Compact Pulse Counter and DC Signal Conditioner for Industrial MonitoringNegotiableMOQ: 1 Combo

-

Honeywell CC-PUI001 — Compact Universal Input Module for Building & Process ControlsNegotiableMOQ: 1 Combo

-

Honeywell FC-PSU-UNI2450U — Universal 24V DC Power Supply for Field ControllersNegotiableMOQ: 1 Combo

-

Honeywell FC-TSRO-0824 — Compact I/O & Signal Conditioning Module for Industrial ControlNegotiableMOQ: 1 Combo

-

Honeywell FC-FANWR-24R — 24V Fan Relay Module for Fan Coil ControlNegotiableMOQ: 1 Combo

-

Honeywell FC-TSKUNI-1624 — Universal Temperature Sensor Interface (16–24 V)NegotiableMOQ: 1 Combo

-

Honeywell FC-TSRO-08UNI — 8-Channel Universal Input Temperature & Signal ModuleNegotiableMOQ: 1 Combo