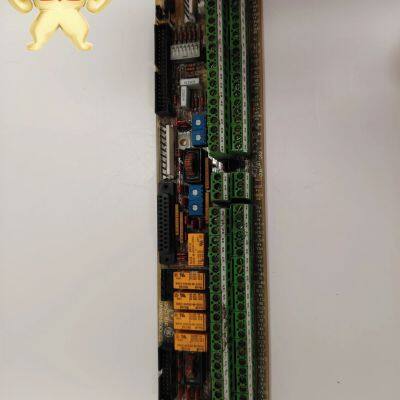

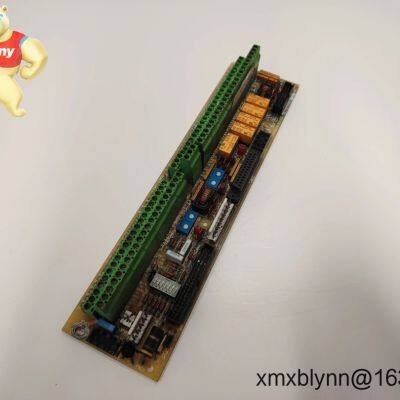

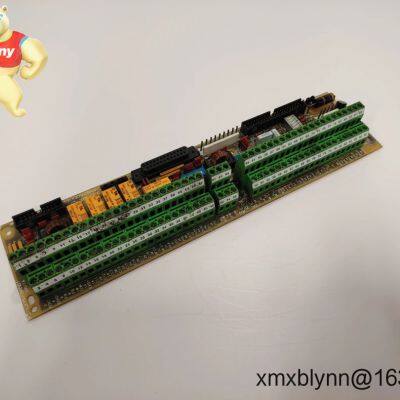

GE 531X305NTBANG1 Terminal Board – Reliable Field I/O Termination for GE Drive Systems

The GE 531X305NTBANG1 (often referred to as NTBA) is a terminal/termination board used in GE industrial drive platforms to bring field wiring into the control system cleanly and safely. It typically handles a mix of analog and digital signals, routes them to the control board via ribbon connectors, and provides basic conditioning and protection. From my experience, plants use it to simplify service work and reduce wiring faults in older but still mission-critical GE drive installations.

Key Features

Purpose-built field termination – Consolidates drive I/O wiring (analog/digital) onto labeled terminal points for consistent, repeatable connections.

Ribbon-cable interconnect – Typically links to the main control board via flat ribbon connectors for quick replacement and minimal downtime.

Analog signal handling – Commonly supports standard industrial ranges such as 0–10 V (and, in many cases, 4–20 mA with appropriate scaling on the host system).

Discrete I/O routing – Brings in 24 VDC logic-level inputs/outputs and dry contacts (exact counts depend on drive build and revision).

Field-friendly design – Pluggable terminal blocks and printed labeling help maintenance teams trace circuits faster.

Serviceability in mind – Board form factor matches the 531X family, making it a practical drop-in for like-for-like replacements.

Revision G1 – The G1 revision typically indicates incremental refinements for compatibility and stability within the 531X line.

| Brand / Model | GE 531X305NTBANG1 (NTBA Terminal Board), Revision G1 |

| Primary Function | Field I/O termination and signal routing to the main control board in GE drive systems |

| Power Requirements | Sourced from the host drive/control backplane; no separate external supply typically required for the board itself |

| Signal I/O Types | Analog (commonly 0–10 V; 4–20 mA in many cases via system scaling), Digital 24 VDC logic-level I/O, dry contacts (counts vary by drive configuration) |

| Communication Interfaces | Not applicable (board-level termination; communicates via internal ribbon/header connectors) |

| Operating Temperature | Typically 0–55°C when installed in a properly ventilated drive cabinet |

| Installation Method | Mounted inside the drive enclosure on standoffs; connects to control board via ribbon cables; field wiring via pluggable terminals |

| Dimensions & Weight | Approx. 280 × 170 mm; ~0.6 kg (typical for 531X board format; may vary slightly by revision) |

This board is commonly found in GE AC and DC drive systems supporting:

Metals processing (rolling mills, coil lines) where analog speed/torque references and robust discrete I/O are the norm

Pulp & paper and textiles lines needing reliable signal termination across long cable runs

Mining, cement, and material handling (conveyors, hoists) with mixed-voltage field devices

Utilities and water/wastewater systems using legacy GE drives still running day-in, day-out

Compatibility – Designed for the 531X drive ecosystem, so it typically drops in without re-engineering the cabinet.

Reduced downtime – Clear terminal labeling and ribbon interconnects speed up swap-outs during unplanned stops.

Cost control – Extends the service life of proven GE drives, avoiding a full retrofit and re-commissioning costs.

Signal integrity – Organized termination helps maintain shielding and grounding practices that keep analog signals stable.

A maintenance lead at a metals plant told us their team shaved hours off fault-finding after standardizing on NTBA-style terminal boards—“we trace, swap, and bring the line back faster than before.”

Cabinet environment – Install in a clean, dry, ventilated enclosure meeting industrial panel standards; maintain ambient within 0–55°C.

Wiring practices – Use shielded cable for analog and feedback signals, route power and signal separately, and bond shields at the recommended end (typically single-point ground).

Safety – De-energize and lock out the drive, discharge stored energy, and observe ESD handling. Verify terminal torque per your plant standard.

Commissioning tips – Confirm jumper/link positions if present; validate analog scaling in the drive controller; function-test discrete I/O.

Routine care – Periodically re-torque terminals, inspect for discoloration or loosened headers, and clean dust with dry, oil-free air. Firmware updates generally apply to the control board, not this terminal board.

Designed for use in GE drive systems that were shipped with CE/UL compliant assemblies; board-level conformity follows the host drive certification.

Manufacturing quality typically aligned with ISO 9001 standards of the era.

RoHS status may vary by production date; many legacy 531X boards pre-date strict RoHS mandates.

Warranty: commonly supplied with a 12-month limited warranty when sourced as a service replacement.

Note: Field counts and exact signal types can vary by drive configuration and revision. If you’re cross-referencing from a removed board, match the full part number including the “G1” revision to ensure fit and function.

Send Inquiry to This Supplier

You May Also Like

-

GE LV5F30-NF – Low-voltage AC Drive for Reliable Motor Control in Pumps, Fans, and ConveyorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0 – Motor Management Relay for Reliable Three‑Phase Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-E-0 Motor Management Relay – Intelligent Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0-0 – Motor Management Relay for Reliable AC Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-F-E-0 – Motor Management Relay for Critical AC Motor Protection and ControlNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0 – Motor Management Relay for Reliable Protection and MonitoringNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-0-0-0 – Motor Management Relay for Dependable Protection and RTD-based Thermal MonitoringNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0-0 Motor Management Relay – Smart Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo

-

GE AT686W Industrial Controller Module – Stable Rack-mounted Control Module for GE Automation SystemsUS$ 3660.00MOQ: 1 Combo

-

FANUC A20B-2001-0065/06A System Master Board – Core CPU/Controller Board for FANUC CNC SystemsUS$ 3216.00MOQ: 1 Blade