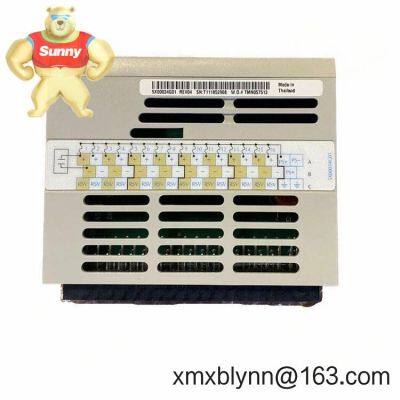

Emerson 5X00034G01 – Reliable Ovation DCS I/O Module for Plant Automation

The Emerson 5X00034G01 is a field-proven I/O module used across Ovation DCS installations to interface process signals with the control system. It’s typically deployed in power generation and water/wastewater plants where stable operation, fast diagnostics, and easy hot-swap maintenance matter day to day. From my experience, it slots in as a straightforward replacement in existing racks with minimal rework.

Ovation DCS Compatibility – Integrates with standard Ovation I/O carriers/backplanes, making it a drop-in part in most brownfield systems.

Hot-Swappable Design – You can replace the module online (in many cases) to reduce downtime and avoid nuisance shutdowns.

Onboard Diagnostics & Status LEDs – Clear health and channel status indicators help technicians troubleshoot faster.

Industrial-Grade Isolation – Channel-to-backplane protection is typical for the series, helping guard the controller from field disturbances.

Redundancy-Friendly – Works within redundant controller and network architectures commonly used in critical utilities.

Consistent Form Factor – Standard Ovation footprint eases cabinet planning and keeps spares logistics simple.

| Brand / Model | Emerson 5X00034G01 |

| System Compatibility | Ovation DCS I/O rack/backplane (5X-series family, typical) |

| Power Requirements | Backplane powered; typical Ovation logic rail. Field power depends on signal type used. |

| Signal I/O | I/O interface module used for process signals in Ovation racks; confirm exact channel type before commissioning. |

| Operating Temperature | Typically 0 to +60 °C for cabinet-mounted I/O (verify by site standard/datasheet). |

| Installation Method | Plugs into Ovation I/O carrier/rack; tool-less latch with keyed alignment, typical. |

| Diagnostics | Module health and channel status LEDs; system diagnostics via Ovation software suite. |

Plants running Ovation typically use the 5X00034G01 for reliable field signal interfacing where consistent uptime is critical. I’ve seen it applied in:

Power generation: gas/steam turbines, HRSG/boiler balance-of-plant, emissions monitoring skids.

Water & wastewater: filtration trains, pump stations, clarifiers, chemical dosing.

Industrial utilities: CHP units, cooling water systems, fuel handling, and packaged process skids.

Pulp & paper and petrochemical auxiliaries where Ovation is the site standard.

Lower Downtime – Hot-swap capability and clear diagnostics streamline replacement during outages or even online, in most cases.

Installed-Base Friendly – Keeps cabinet layouts, wiring looms, and spares strategy consistent across units.

Proven Reliability – Designed for utility environments with electrical noise and temperature swings.

Cost Control – Familiar footprint and process tie-ins reduce engineering cost when expanding or modernizing I/O.

A maintenance lead at a combined-cycle plant mentioned they swapped a 5X00034G01 mid-shift and restored a transmitter loop in minutes—no re-landing of field wires, no controller reboot. That’s exactly the kind of small win that tends to add up over a season.

Installation & MaintenanceCabinet & Rack – Mount in a clean, ventilated control cabinet; follow Ovation rack spacing and grounding practices.

Wiring & Shielding – Maintain shield terminations per site standard; separate low-level analog from high-voltage conductors.

ESD Precautions – Use wrist straps and handle by edges; power and I/O should be isolated before removal unless system policy allows hot-swap.

Commissioning – Verify module type mapping in Ovation software; match firmware/hardware revisions if the controller set enforces it.

Routine Care – Periodic cabinet dusting, connector reseat checks during planned outages, and backup of configuration databases.

Manufactured to ISO 9001 quality systems (Emerson production standards).

Typically meets CE and UL requirements for industrial control equipment; RoHS status depends on region and build date.

Standard manufacturer warranty is commonly 12 months from shipment; extended coverage can be arranged in many cases.

Note: The 5X00034G01 designation aligns with the Ovation 5X-series I/O family. Channel type and exact electrical characteristics can vary by revision and application, so I recommend confirming your installed rack, firmware expectations, and signal mix before we ship. If you share a photo of the existing slot and controller revision, I can double-check compatibility quickly.

Send Inquiry to This Supplier

You May Also Like

-

EMERSON 5X00226G02 Solid-State Relay Output Module – Clean, Durable Digital Switching for DCS ApplicationsNegotiableMOQ: 1 Combo

-

EMERSON 5X00226G03 – Ovation I/O Module for Dependable DCS Signal Processing and Spares CoverageNegotiableMOQ: 1 Combo

-

EMERSON 5X00241G02 – Ovation I/O Module for Reliable Field Signal IntegrationNegotiableMOQ: 1 Combo

-

Emerson 5X00270G01 Ovation I/O Module – Reliable Field Signal Interface for Installed Ovation DCSNegotiableMOQ: 1 Combo

-

EMERSON 5X00300G02 – Ovation I/O Module for Stable, Plant‑wide ControlNegotiableMOQ: 1 Combo

-

Emerson 5X00321G01 – Ovation DCS Module for Reliable I/O Interface and System UpkeepNegotiableMOQ: 1 Combo

-

EMERSON 5X00357G03 Ovation I/O Module – Stable Field Signal Interface for Critical ControlNegotiableMOQ: 1 Combo

-

EMERSON 5X00419G01 – Ovation DCS Module for Reliable Field I/O Integration and System MaintenanceNegotiableMOQ: 1 Combo

-

EMERSON 5X00481G01 – Ovation I/O Module for Reliable Field Signal IntegrationNegotiableMOQ: 1 Combo

-

EMERSON 5X00481G04 – Ovation DCS I/O Module for Dependable Plant Signal InterfacingNegotiableMOQ: 1 Combo