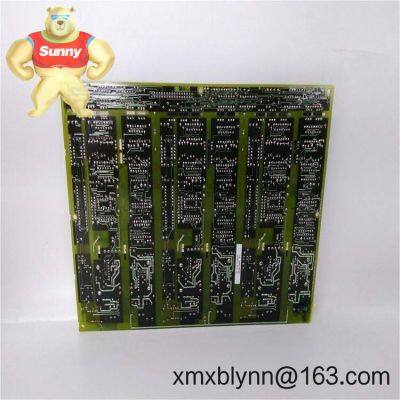

GE 531X304IBDARG1 PC Basic Driver Card – Reliable Signal Interface for Legacy GE Drive Platforms

The GE 531X304IBDARG1 is a PC Basic Driver Card engineered for GE industrial AC/DC drive systems in the 531X/DS200 family. It typically handles logic-level signal conditioning, drive interface, and gate-drive preconditioning so your inverter or converter section receives clean, properly timed control signals.

From my experience, this board is used as a drop-in service replacement to recover production quickly—especially when a legacy cabinet needs stable control without reengineering the entire drive. You might notice that most teams keep one on the shelf to minimize downtime during planned overhauls.

Signal conditioning and distribution – Buffers and routes logic/control signals to the power section with stable timing.

Backplane-powered – Typically draws regulated rails from the host drive; no separate PSU wiring simplifies service.

Form-fit-function replacement – Designed as a like-for-like board in GE drive cabinets, reducing the need for wiring changes.

Diagnostics support – Test points and labeled headers make commissioning and troubleshooting faster in most cases.

Robust component selection – Industrial-grade parts for electrical noise environments common in motor control rooms.

| Brand / Model | GE (General Electric) / 531X304IBDARG1 |

| Function | PC Basic Driver Card for logic signal conditioning and drive interface |

| Power Requirements | Supplied via drive backplane (logic rails; +5 V and auxiliary analog rails are typical for this series) |

| Signal I/O Types | Logic-level control, timing/trigger lines, and pre-driver outputs (varies by cabinet build) |

| Communication Interfaces | Edge connectors and pin headers to the drive backplane and harnesses |

| Operating Temperature | 0 to 60°C (typical cabinet environment for GE drive electronics) |

| Dimensions & Weight | Standard 531X board format; single-board assembly (approx. 280 × 200 mm, ≤0.6 kg typical) |

| Installation Method | Internal mounting within GE drive enclosure using standoffs and multi-pin connectors |

This board is commonly used in production lines where GE legacy drives remain the standard: metals processing, pulp & paper, cement, mining, water/wastewater, and general OEM machinery. In many cases it restores control integrity without touching the power stack or motor wiring.

One thing I appreciate is how it helps maintenance teams keep older systems running while planning a phased migration. A plant we support used the 531X304IBDARG1 to stabilize a winder drive, cutting nuisance trips by half after a simple board swap and connector clean.

Advantages & ValueReliability in harsh environments – Built for electrical noise found near VFDs, contactors, and high-current busbars.

True drop-in replacement – Minimizes downtime; typically no rewiring or code changes when replacing like-for-like.

Cost control – Extends the life of existing GE drive assets and avoids an unplanned full retrofit.

Compatibility – Works within established GE 531X/DS200 architectures, easing spare parts management.

Serviceability – Clear labeling and accessible test points support faster diagnostics.

Cabinet conditions – Install in a clean, dry, ventilated enclosure. Maintain ambient 0–60°C and avoid condensation.

ESD and handling – Use wrist straps and ESD-safe work surfaces. De-energize the drive and discharge DC bus before any work.

Mounting & wiring – Seat the board on standoffs; verify all edge connectors are fully mated. Check jumper/DIP positions against your drive’s build sheet.

Commissioning – After power-up, verify status LEDs (if present), confirm reference and feedback signals at test points, and run a controlled start.

Routine care – Quarterly dust removal using dry, oil-free air; inspect headers for oxidation; re-seat connectors annually. No firmware updates are typically required for this board.

Manufacturing quality – Produced under GE quality systems (ISO 9001 at the time of manufacture).

System certifications – Intended for use within UL/CE-certified GE drive systems; the board itself is a service component.

RoHS – Legacy spare; leaded solder may be present (RoHS exemption typically applies for maintenance of existing equipment).

Warranty – Typically supplied with a limited warranty by the distributor; many customers opt for 12-month coverage on refurbished units.

Send Inquiry to This Supplier

You May Also Like

-

GE Multilin 750-P1-G1-S1-HI-A20-G – Feeder Protection Relay for Reliable MV/LV DistributionNegotiableMOQ: 1 Combo

-

GE PAC8000 8521-HC-MT – HART Maintenance Access for Remote Field I/ONegotiableMOQ: 1 Combo

-

GE LV5F30-NF – Low-voltage AC Drive for Reliable Motor Control in Pumps, Fans, and ConveyorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0 – Motor Management Relay for Reliable Three‑Phase Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-E-0 Motor Management Relay – Intelligent Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0-0 – Motor Management Relay for Reliable AC Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-F-E-0 – Motor Management Relay for Critical AC Motor Protection and ControlNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0 – Motor Management Relay for Reliable Protection and MonitoringNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-0-0-0 – Motor Management Relay for Dependable Protection and RTD-based Thermal MonitoringNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0-0 Motor Management Relay – Smart Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo