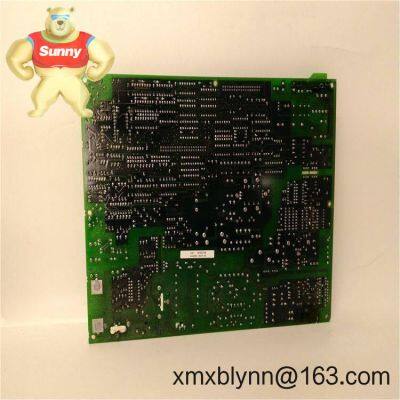

GE 531X303MCPBBG1 Main Control Power Board – Stable AC-to-DC Control Power for GE Drive and Excitation Systems

The 531X303MCPBBG1 is part of GE’s MCPB series, designed to convert incoming AC control power into the regulated low-voltage rails used by drive control electronics. In most cases, you’ll find this board supporting GE AC/DC drive families and excitation platforms where reliable, clean control power is non‑negotiable. From my experience, it’s a straightforward drop‑in for many cabinets built around the 531X series architecture.

Typical use is to feed logic, I/O conditioning, and relay circuits with stable +5 V and ±15 V supplies (varies by build), with onboard protection that helps ride through noise and minor surges common in industrial environments.

AC control input handling – Accepts standard control AC (typically 115–230 VAC, 50/60 Hz) and conditions it for sensitive electronics.

Regulated low-voltage rails – Provides +5 V and ±15 V outputs in many cases, stabilizing logic and analog sections for consistent drive behavior.

Integrated protection – Onboard fuses, MOVs, and snubbers help absorb transients and protect downstream circuits.

Service-friendly layout – Clearly labeled test points, fuses, and connectors make troubleshooting quicker during downtime.

Connector compatibility – Ribbon headers and terminal blocks align with the 531X series harnessing, easing swap‑outs in the field.

Stable performance under load – Designed for cabinet temperatures typically up to 55°C, provided ventilation is adequate.

| Brand / Model | GE 531X303MCPBBG1 (MCPB series) |

| Power Requirements | Control AC input, typically 115–230 VAC, 50/60 Hz (system-dependent) |

| Outputs (typical) | Low-voltage DC rails for control logic (e.g., +5 V, ±15 V); actual rails depend on revision/build |

| Signal I/O Types | AC input, fused outputs, relay drive, ribbon headers to control sections, terminal blocks for AC/ground |

| Communication Interfaces | Not a network card; provides power and control interconnects via keyed headers/terminal blocks |

| Installation Method | Panel/rack mounted inside GE 531X‑based cabinets using standoffs and harness connectors |

| Dimensions & Weight | Approx. 12 × 8 in (305 × 203 mm); ~0.8–1.0 kg, varies by revision |

| Operating Temperature | 0 to +55°C typical, within a ventilated, closed cabinet |

You’ll typically see the 531X303MCPBBG1 in GE AC/DC drives and excitation systems deployed in:

Metals and rolling mills – stable control power helps keep drives synchronized under heavy load swings.

Pulp & paper – reduces nuisance trips from line noise in humid, high‑debris environments.

Mining & hoisting – solid ride‑through performance during brief sags and starts.

Power generation (excitation cabinets) – consistent low-voltage rails for regulator and protection logic.

Oil & gas – supports PLC/drive cabinets where clean control power is critical for interlocks.

Drop‑in replacement – Form/fit match for many 531X installations speeds changeouts and recovery.

Reliability in harsh cabinets – Robust components and fusing reduce the ripple effects of plant‑level power disturbances.

Lower lifecycle cost – Extends the service life of installed GE drives without a costly full cabinet upgrade.

Compatibility – Works with common GE harnessing and connector schemes; fewer surprises during commissioning.

Supportability – Easy access to fuses and test points simplifies preventive maintenance and fault isolation.

“We replaced the MCPB during a planned stop and had the line back up in under an hour. Voltage rails were spot‑on without any tuning.” — Maintenance Supervisor, steel processing plant

Installation & MaintenanceEnvironment – Mount inside a closed, ventilated cabinet; maintain airflow and keep ambient below 55°C.

Wiring – Follow the cabinet wiring diagram; confirm AC control voltage range, ground bonding, and fuse ratings before energizing.

ESD & safety – Lockout/tagout, discharge stored energy, and use ESD protection when handling the board.

Jumpers/taps – Verify any input taps or jumpers (if present) match your control AC and system configuration.

Routine care – Inspect and replace fuses as required, check connector tightness, and clean dust quarterly with dry air.

Calibration – Measure output rails under load during commissioning; no firmware on the board itself, so no field updates usually needed.

Compliance – When installed in a certified GE drive/excitation cabinet, the assembly typically meets CE and UL system listings; RoHS compliance varies by production date.

Testing – Units are commonly function‑tested for output rails, regulation, and fault protection before shipment.

Warranty – Warranty terms depend on supply channel; a 12‑month limited warranty from the ship date is typical for refurbished or new‑surplus stock.

Send Inquiry to This Supplier

You May Also Like

-

GE 531X307LTBAHG1 LAN Terminal Board – Reliable Field I/O and LAN Termination for Legacy GE Drive SystemsNegotiableMOQ: 1 Combo

-

GE 531X307LTBAJG1 LAN Terminal Board – Reliable Field Wiring Interface for GE Drive NetworksNegotiableMOQ: 1 Combo

-

GE Multilin 750-P1-G1-S1-HI-A20-G – Feeder Protection Relay for Reliable MV/LV DistributionNegotiableMOQ: 1 Combo

-

GE PAC8000 8521-HC-MT – HART Maintenance Access for Remote Field I/ONegotiableMOQ: 1 Combo

-

GE LV5F30-NF – Low-voltage AC Drive for Reliable Motor Control in Pumps, Fans, and ConveyorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0 – Motor Management Relay for Reliable Three‑Phase Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-E-0 Motor Management Relay – Intelligent Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0-0 – Motor Management Relay for Reliable AC Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-F-E-0 – Motor Management Relay for Critical AC Motor Protection and ControlNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0 – Motor Management Relay for Reliable Protection and MonitoringNegotiableMOQ: 1 Combo