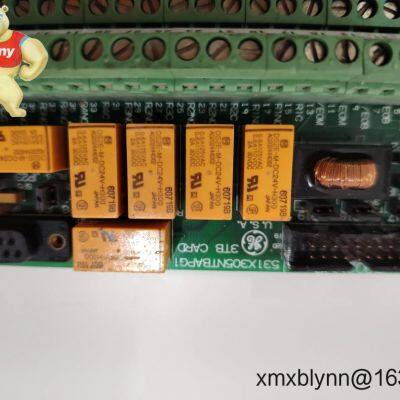

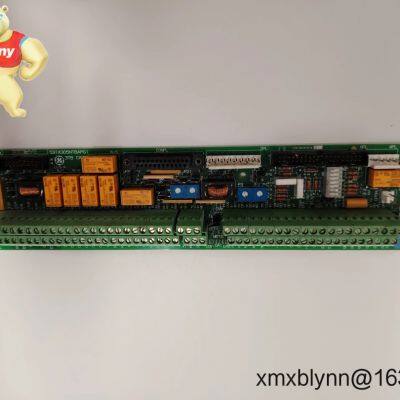

GE 531X305NTBAPG1 – NTBA Terminal Board for Field I/O Termination in Legacy GE Drives and Control Systems

The GE 531X305NTBAPG1 (often referenced as an NTBA terminal board) is a field I/O termination platform used in GE legacy drive and control packages. In practical terms, it serves as the landing point between cabinet wiring and the controller, handling mixed discrete and analog signals with basic filtering and protection. It’s typically chosen to keep legacy GE systems running reliably, especially where a drop-in electrical fit is needed to minimize downtime.

Field I/O termination – Screw terminals provide a tidy, serviceable interface for cabinet wiring to the control electronics.

Mixed-signal handling – Typically accommodates 24 VDC digital inputs/outputs and low-level analog signals (such as ±10 V or 4–20 mA), depending on system configuration.

Onboard protection and conditioning – You might notice RC filtering, surge suppression, and opto-isolation in many builds, which helps reduce noise and nuisance trips.

Ribbon/edge interconnects – From my experience, the board mates to the controller via ribbon cable headers or edge connectors common to the GE 531X/DS200 family.

Service-friendly layout – Clear terminal labeling and separation of analog vs. digital points make field checks and troubleshooting faster.

Legacy system continuity – Suited as a replacement in older GE drive and excitation cabinets where keeping the existing wiring harness is key.

This board shows up in mature GE platforms used across heavy industry. You’ll typically see it in:

Steel and metals processing lines where mixed analog/digital I/O needs robust termination in noisy environments.

Pulp & paper mills, especially on legacy GE drives still running reliably after many years.

Mining and cement facilities where downtime avoidance is more valuable than a complete controls redesign.

Power generation auxiliaries and excitation systems that favor drop-in maintenance parts over platform changes.

General industrial retrofits when maintaining existing harnesses and terminations saves commissioning time.

Reduced downtime – It seems to be a straightforward electrical fit in many GE legacy cabinets, so swap-outs are quicker.

Compatibility – The NTBA layout is well known in the 531X/DS200 family; still, verifying pin-out and revision against your controller is the safe move.

Lower retrofit risk – Keeps existing field wiring and signal scaling intact in most cases, avoiding a snowball of rewiring.

Serviceability – Clear terminals and accessible test points help maintenance teams diagnose issues fast.

Lifecycle support – A practical option to extend the usable life of installed GE assets while planning long-term upgrades.

Cabinet & mounting – Install in a clean, ventilated control cabinet. Use the original standoff pattern; maintain adequate clearance around terminal strips.

Wiring practices – Separate analog from high-voltage cabling, shield analog pairs, and bond shields at the recommended single point to cut down noise.

Terminal torque – Re-torque screw terminals after initial thermal cycles; loose terminations are a common, preventable fault.

ESD handling – Handle the board with ESD precautions; store in antistatic packaging when off the machine.

Jumper/settings – Some NTB variants include jumpers or configurable ranges. Confirm positions match your controller’s I/O expectations before energizing.

Routine checks – Inspect for discoloration, damaged traces, or buildup of dust. Clean with approved electronics cleaner; avoid moisture.

A maintenance lead at a paper plant told us they swapped a worn NTBA for the 531X305NTBAPG1 during a 4‑hour window—no rework on harnesses, and their analog scaling lined up right away. That’s fairly typical when the revision matches the installed controller.

Manufacturing quality – Produced under GE’s quality system (commonly aligned with ISO 9001 practices for industrial electronics).

CE/UL context – Compliance is typically tied to the complete drive/control assembly; this board is intended for use within that certified system.

RoHS – Depending on build date and region, earlier legacy boards may not be RoHS. If that’s a requirement, specify at time of order.

Warranty – Standard limited warranty terms (often 12 months repair/replace) are available; exact coverage can vary by supply channel and condition (new, surplus, or refurbished).

If you’re replacing an existing NTBA, match the model and revision (531X305NTBAPG1) against your installed controller documentation and backplane connector map. When in doubt, share a photo of your current board’s terminal layout and connector labels—we can cross-check compatibility and any required jumper positions before you schedule the changeout.

Send Inquiry to This Supplier

You May Also Like

-

GE Multilin 369-HI-0-M-0-0 – Motor Management Relay for Reliable Three‑Phase Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-E-0 Motor Management Relay – Intelligent Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0-0 – Motor Management Relay for Reliable AC Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-F-E-0 – Motor Management Relay for Critical AC Motor Protection and ControlNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0 – Motor Management Relay for Reliable Protection and MonitoringNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-0-0-0 – Motor Management Relay for Dependable Protection and RTD-based Thermal MonitoringNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0-0 Motor Management Relay – Smart Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo

-

GE AT686W Industrial Controller Module – Stable Rack-mounted Control Module for GE Automation SystemsUS$ 3660.00MOQ: 1 Combo

-

FANUC A20B-2001-0065/06A System Master Board – Core CPU/Controller Board for FANUC CNC SystemsUS$ 3216.00MOQ: 1 Blade

-

GE DS200ADPBG1ABB Genius Adapter Board – Reliable Genius Bus Interface for Mark V and GE Drive SystemsUS$ 3216.00MOQ: 1 Blade