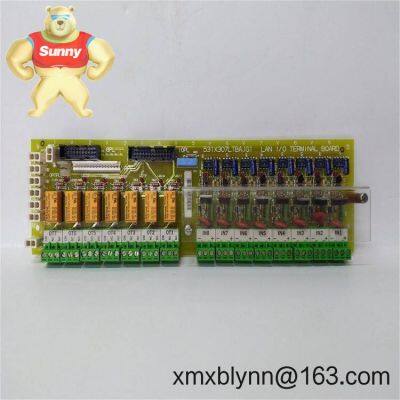

GE 531X307LTBAJG1 LAN Terminal Board – Reliable Field Wiring Interface for GE Drive Networks

The GE 531X307LTBAJG1 (LAN Terminal Board) is a field‑proven interface board designed to terminate and route LAN/serial communication signals inside GE industrial drive systems. It typically sits between the controller and plant cabling, providing clean, labeled connection points, termination options, and basic diagnostics for maintenance.

From my experience, plants use this board to keep legacy GE drive networks stable—especially where RS‑485/RS‑422 multi‑drop links and shielded twisted‑pair runs are standard. It’s a straightforward, drop‑in hardware piece that helps reduce noise issues and makes service work faster.

Purpose-built LAN termination – Provides organized screw-terminal landings for drive LAN/serial links, typically RS‑485/RS‑422 style multi‑drop connections.

On-board termination/bias jumpers – Selectable end‑of‑line termination and biasing, so you can stabilize long cable runs without external resistors.

Status indicators – You might notice simple LEDs (e.g., PWR/TX/RX or link health) that give quick visual checks during commissioning or fault tracing.

Noise-reduction layout – Filtering and proper shield/drain termination points help cut down interference in cabinets with VFDs and high-current equipment.

Direct fit in GE 531X/DS200-based systems – Typically used in GE drives and related control frames, with mounting holes and connectors aligned to standard locations.

Service-friendly labeling – Clear terminal designations make field wiring and documentation updates noticeably easier for maintenance teams.

Compatible with existing cabling – Works with shielded twisted pair commonly used for plant networks, easing retrofit jobs.

| Brand / Model | GE 531X307LTBAJG1 (LAN Terminal Board) |

| Function | LAN/serial wiring termination and routing inside GE drive/control cabinets |

| Power Requirements | Draws low-level board power from the host assembly; no external supply required |

| Operating Temperature | Typically 0 to 60 °C (cabinet‑mounted, non‑condensing environment) |

| Signal I/O Types | Differential serial channels (commonly RS‑485/RS‑422 style), shield/drain terminations, screw terminals |

| Communication Interfaces | Supports multi‑drop serial LAN within GE drive systems; termination/bias selectable via jumpers |

| Installation Method | Mounts in GE drive/control frame using standoffs; field wiring via labeled screw terminals |

This board is commonly found in GE industrial drive platforms where deterministic, robust serial networking is preferred. Typical deployments include:

Steel and metals lines (continuous casters, pickling lines, rolling mills) where RS‑485 networks tie drives and controllers together.

Pulp & paper converting and winders that rely on multi‑drop LAN cabling inside large control cabinets.

Mining and aggregate conveyors using GE drives with long cable runs and strict noise immunity needs.

Power generation auxiliaries and test stands with legacy GE control racks that still need dependable LAN terminations.

Drop‑in fit for the installed base – Keeps existing GE 531X/DS200 system wiring schemes intact, minimizing downtime.

Cleaner commissioning – On‑board jumpers and labeled terminals make it easier to get networks stable without guesswork.

Lower noise risk – Proper shield landings and filtering help reduce nuisance comms faults in high‑EMI environments.

No reprogramming – It’s a hardware termination layer; in most cases you won’t touch the logic or firmware upstream.

Lifecycle support – A practical way to extend legacy GE drive networks while planning phased upgrades.

Field note: A maintenance lead at a metals plant mentioned that swapping to a fresh 531X307LTBAJG1 and re‑setting the RS‑485 termination cured intermittent link alarms that had chased them for weeks. It seems to be the small things—proper biasing and clean shields—that stabilize these networks.

Cabinet standards – Mount inside a clean, ventilated control cabinet; maintain separation from high‑voltage power cables.

Wiring practice – Use shielded twisted pair for serial runs; land shields at the designated clamp/terminal to avoid ground loops.

Termination – Enable end‑of‑line termination and biasing only at the network ends; intermediate nodes typically remain unterminated.

Torque and strain relief – Tighten terminal screws to spec and secure cables with tie‑downs to prevent vibration fatigue.

ESD & handling – Treat as a static‑sensitive PCB; power down and discharge before removal/installation.

Routine checks – Inspect terminals for loosening, look over LEDs during startup for quick health cues, and clear dust with dry air.

Firmware – No firmware to manage on this board, which simplifies maintenance schedules.

CE compliant when installed within the intended GE drive/control system.

UL recognized components; produced under typical ISO 9001 manufacturing processes.

RoHS status may vary by production lot/revision; confirm if your site requires documented RoHS compliance.

Warranty: commonly supplied with a 12‑month limited hardware warranty from the distributor or repair house.

Plants often pair the 531X307LTBAJG1 with GE controller and I/O boards from the 531X/DS200 families (e.g., CPU/control boards and communication interface cards). If you’re refreshing a cabinet, it’s sensible to review the upstream comms card and any external repeaters or isolators at the same time.

Send Inquiry to This Supplier

You May Also Like

-

GE Multilin 369-HI-0-M-0-0-0 – Motor Management Relay for Reliable AC Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-F-E-0 – Motor Management Relay for Critical AC Motor Protection and ControlNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0 – Motor Management Relay for Reliable Protection and MonitoringNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-0-0-0 – Motor Management Relay for Dependable Protection and RTD-based Thermal MonitoringNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0-0 Motor Management Relay – Smart Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo

-

GE AT686W Industrial Controller Module – Stable Rack-mounted Control Module for GE Automation SystemsUS$ 3660.00MOQ: 1 Combo

-

FANUC A20B-2001-0065/06A System Master Board – Core CPU/Controller Board for FANUC CNC SystemsUS$ 3216.00MOQ: 1 Blade

-

GE DS200ADPBG1ABB Genius Adapter Board – Reliable Genius Bus Interface for Mark V and GE Drive SystemsUS$ 3216.00MOQ: 1 Blade

-

GE DS200CTBAG1ADD – Contactor/Terminal Board for Reliable Discrete I/O TerminationUS$ 3216.00MOQ: 1 Blade

-

GE DS200DCFBG1BKC – Power Distribution/Power Supply Board for Mark V CabinetsUS$ 3216.00MOQ: 1 Blade