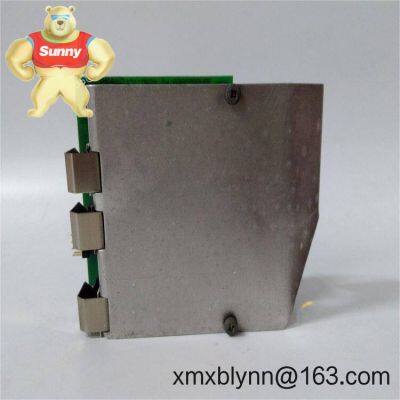

ABB 3BHB003688R0001 IGCT Module – High‑power Switching Element for Medium‑voltage Drives and Converters

The ABB 3BHB003688R0001 is an IGCT (Integrated Gate-Commutated Thyristor) module built for heavy-duty, medium-voltage power conversion. It’s typically used in ABB MV drives and high-power converters where efficiency, ruggedness, and long service life matter more than anything else. From my experience, this module fits well in applications that run around the clock—cement kilns, metals lines, or marine propulsion—where downtime is simply too costly.

IGCT power technology: Combines low conduction losses with fast, reliable turn‑off, ideal for medium-voltage, high-current duty.

Press-pack, field-proven design: Uniform pressure contact helps manage thermal cycling and enhances long-term reliability under load swings.

Rugged for industrial environments: In many cases, these modules perform steadily in harsh conditions—dusty mills, high-vibration plant floors—when mounted correctly.

Stable at high power: Suited to multi-megawatt converters, MV drives, STATCOM/SVC, and large synchronous motor controls.

Service-friendly replacement: Typically drop‑in for the intended drive generation, minimizing retrofit work and re-qualification effort.

Thermal management readiness: Designed for press-pack clamping between heatsinks, making heat path predictable and repeatable with proper torque.

Traceability support: Clear model coding and batch traceability, which procurement teams often ask for during audits.

| Brand / Model | ABB 3BHB003688R0001 |

| Device Type | IGCT power module (Integrated Gate‑Commutated Thyristor) |

| Typical Application | Medium‑voltage drives, high‑power rectifiers/inverters, STATCOM/SVC, propulsion, large compressors/fans |

| Signal I/O | Gate drive via matched ABB gate unit; anode/cathode press‑pack terminals |

| Power Requirements | Gate unit supply typically 24 VDC (driver side) |

| Installation Method | Press‑pack clamped between heatsinks; calibrated clamping force; proper thermal interface |

| Communication Interfaces | Not applicable to the semiconductor; interfaces handled by the drive’s control and gate unit |

You’ll typically find the 3BHB003688R0001 in medium‑voltage drives used across heavy industry. It seems to be a strong fit where long duty cycles and load variations are the norm.

Metals and mining: MV rolling mills, hoists, slurry pumps, conveyor drives needing high torque stability.

Cement and minerals: Kiln and raw mill fans where continuous operation and thermal robustness are critical.

Oil & gas / Petrochemical: Large compressors and pumps with stringent uptime requirements.

Power quality and utilities: STATCOM/SVC converters for grid stabilization and reactive power control.

Marine and transportation: Propulsion drives and high-power auxiliary systems.

Reliability under load: IGCT topology offers low conduction losses and robust SOA, reducing thermal stress in MV stacks.

Lifecycle continuity: Supports existing ABB drive fleets, helping avoid premature retrofit of entire power stacks.

Compatibility: Built for ABB ecosystems, making integration and commissioning straightforward in most cases.

Operating cost control: Efficient switching and predictable thermal behavior can help lower cooling and maintenance costs over time.

Documentation & traceability: Clear part coding supports spares planning, audits, and root-cause investigations.

Cabinet/heatsink setup: Use clean, flat heatsink surfaces; verify cabinet ventilation and airflow; keep dust away from clamping interfaces.

Clamping force: Apply the manufacturer‑specified clamping force with a calibrated tool. Uneven pressure can shorten lifetime.

Thermal interface: Use approved thermal compound or pads; apply a consistent, thin layer to avoid hot spots.

Wiring & gate unit: Route gate leads per ABB practices; keep them short and shielded as required by the gate unit specification.

Safety: De-energize and discharge all DC link capacitors; observe MV/LV isolation and lockout/tagout procedures.

Routine checks: Inspect clamping hardware torque, clean dust from heatsinks, and monitor temperature sensors during PM rounds.

Drive firmware: If the module is replaced in a running drive, confirm gate unit parameters and the drive’s firmware compatibility during recommissioning.

ABB IGCT Gate Unit (matched to the drive generation): Ensures proper gate current profile and protection timing.

Snubber network (capacitor/resistor assembly): Helps manage dv/dt and transient energy in the stack.

Calibrated clamping set: Maintains specified force across the press-pack during operation.

Approved thermal compound: For consistent thermal conductivity and repeatable assembly quality.

Quick note from a maintenance lead we worked with: replacing a worn IGCT module and re‑torquing the clamping set brought their MV fan drive temperatures down by a few degrees, which, in many cases, is enough to stabilize trips during summer peaks.

Quality & CertificationsManufactured under ISO 9001 quality systems.

RoHS/REACH compliance for component materials (typical for ABB power semiconductors).

Component-level CE/UL marking is generally not applicable; compliance is assessed at the drive/system level.

Standard warranty: typically 12 months from delivery when installed per manufacturer guidance.

Send Inquiry to This Supplier

You May Also Like

-

ABB 5SHY35L4522 IGCT Gate Unit – Trusted Drive Control for High‑power ConvertersNegotiableMOQ: 1 Combo

-

ABB 07AI91 (GJR5251600R4202) – Analog Input Module for AC31/CS31 Process ControlNegotiableMOQ: 1 Combo

-

ABB 07BR61R1 (GJV3074376R1) – MasterBus 300 Repeater for Segment Isolation and Distance ExtensionNegotiableMOQ: 1 Combo

-

ABB 07DC91 (GJR5251400R0202) – Digital Control/communication Module for Legacy Procontrol/Advant 07-series SystemsNegotiableMOQ: 1 Combo

-

ABB 07EA90-SI (GJR5251200R0101) – System Interface Module for Advant Master S100 I/ONegotiableMOQ: 1 Combo

-

ABB 07KT94 (GJR5252100R3261) – Communication/Processor Module for Advant Controller 31 (AC31) SystemsNegotiableMOQ: 1 Combo

-

ABB 086318-002 / 086318-501 – Legacy I/O Termination Assembly for ABB Bailey INFI 90 / NET 90 CabinetsNegotiableMOQ: 1 Combo

-

ABB 086329-004 – Legacy DCS Module for ABB Bailey INFI 90 Maintenance and SparesNegotiableMOQ: 1 Combo

-

ABB 086339-501 – Field-Replaceable Industrial Control Module for Legacy ABB DCS RacksNegotiableMOQ: 1 Combo

-

ABB 086345-004 – Replacement Control Module for Legacy ABB Bailey DCS RacksNegotiableMOQ: 1 Combo