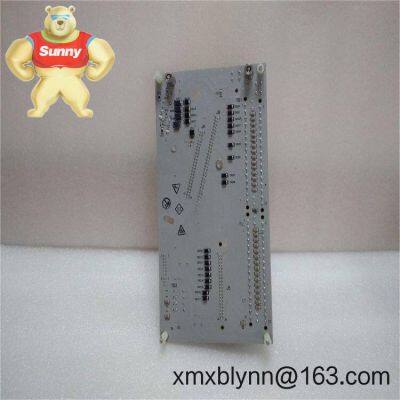

HONEYWELL 51304644-175 – OEM Control System Module for TPS/Experion Maintenance and Uptime

The HONEYWELL 51304644-175 is an original spare part used in legacy and migration-ready Honeywell process control systems (commonly TPS/TDC 3000 and many Experion PKS environments). In most cases it’s sourced to keep critical I/O or controller bays healthy, ensuring production stays online with a form-fit-function match to the installed base.

From my experience, plants typically deploy this part during preventive turnarounds or as an immediate swap when a slot-level fault occurs. It’s a pragmatic way to extend system life without rushing a full platform upgrade.

Exact Part-Number Match: 51304644-175 aligns with Honeywell’s OEM specifications for straightforward replacement and minimal engineering effort.

Form, Fit, Function Compatibility: Designed to slot into existing Honeywell cabinets or card files with no wiring rework in typical cases.

Stable Lifecycle Support: Commonly used to extend TPS/TDC 3000 and Experion PKS system availability while migration plans take shape.

Traceability and QA: Supplied with traceable labeling and, typically, ESD-safe packaging for safe handling on the plant floor.

Reliability Under Plant Conditions: Built for cabinet-mounted environments, with robust connectors and materials that handle 24/7 duty.

Service-Friendly: Plug-in replacement that reduces MTTR; technicians can perform checks and loop validation quickly after installation.

| Brand / Model | HONEYWELL 51304644-175 |

| Product Type | OEM control system module / spare for Honeywell DCS platforms |

| System Compatibility | Typically used in Honeywell TPS (TDC 3000) and many Experion PKS cabinets; verify against installed bill of materials |

| Power Requirements | Backplane/chassis supplied (when applicable to the module function) |

| Operating Temperature | 0 to 55°C typical for cabinet-mounted modules |

| Installation Method | Plug-in to system chassis/card file; panel/cabinet installation per Honeywell system design |

Plants usually keep 51304644-175 on the shelf for fast swap-outs in:

Refining and petrochemical units (FCC, hydrotreaters, reformers)

Chemical and specialty chemical batch/continuous processes

Power generation (boiler/turbine auxiliaries, BOP)

Pulp & paper and metals (consistent with older Honeywell DCS estates)

Gas processing and midstream compression skids

One thing I appreciate is how it helps facilities keep proven loops running while they plan phased modernizations. You might notice that procurement teams often pair this with spare FTAs or chassis parts to streamline maintenance windows.

Reduced Downtime: Like-for-like replacement shortens troubleshooting and recovery time.

Risk Mitigation: OEM part number alignment lowers integration risk compared with generic substitutes.

Lifecycle Strategy: Supports a staged migration path rather than a disruptive cutover.

Inventory Simplicity: Clear traceability and revision control simplify storeroom management.

Technical Backing: Documentation and field-proven practices exist widely across Honeywell-installed bases.

A maintenance supervisor told us their team swapped a failed slot with 51304644-175 during a weekend outage and cleared alarms within an hour—no rewiring, just reseat, tighten, and revalidate. That seems to be the typical experience when the part matches the cabinet’s BOM.

Installation & MaintenanceCabinet Environment: Maintain clean, ventilated panels. Keep ambient temperature within 0–55°C and humidity controlled.

Handling & Safety: De-energize the affected cabinet or slot as required by site procedures. Use ESD protection when unboxing and installing.

Mounting: Seat the module fully in the chassis/card file. Verify backplane connector engagement; avoid lateral stress on the board.

Wiring & Strain Relief: If interface cabling or FTAs are involved, check terminal torque and provide strain relief to prevent intermittent faults.

Commissioning Checks: After replacement, perform loop checks, confirm I/O status, and align any required firmware or configuration (where applicable).

Routine Care: Periodic cabinet dust removal, visual inspection of connectors, and alignment with site firmware standards help maintain stability.

Manufactured to HONEYWELL quality standards; production typically aligned with ISO 9001 practices

CE/UL/RoHS conformity is commonly applicable for cabinet-mounted DCS modules (verify per shipment)

Standard HONEYWELL limited warranty; coverage term may vary by region and service agreement

Plants often pair 51304644-175 with spare FTAs (field termination assemblies), backplane/chassis slots, and pre-terminated interface cables to streamline swap-outs. If you share your cabinet code and slot function, we can cross-check compatibility and suggest a small spares kit that typically pays for itself after a single avoided shutdown.

Send Inquiry to This Supplier

You May Also Like

-

Honeywell CC-PAIX02 (51405038-476) — I/O & Interface Expansion Module for Control CabinetsNegotiableMOQ: 1 Combo

-

Honeywell CC-PWRR01 51199929-100 — Redundant Power Module for CC ControllersNegotiableMOQ: 1 Combo

-

Honeywell CC-PCNT02 + DC-TCNT01 — Compact Pulse Counter and DC Signal Conditioner for Industrial MonitoringNegotiableMOQ: 1 Combo

-

Honeywell CC-PUI001 — Compact Universal Input Module for Building & Process ControlsNegotiableMOQ: 1 Combo

-

Honeywell FC-PSU-UNI2450U — Universal 24V DC Power Supply for Field ControllersNegotiableMOQ: 1 Combo

-

Honeywell FC-TSRO-0824 — Compact I/O & Signal Conditioning Module for Industrial ControlNegotiableMOQ: 1 Combo

-

Honeywell FC-FANWR-24R — 24V Fan Relay Module for Fan Coil ControlNegotiableMOQ: 1 Combo

-

Honeywell FC-TSKUNI-1624 — Universal Temperature Sensor Interface (16–24 V)NegotiableMOQ: 1 Combo

-

Honeywell FC-TSRO-08UNI — 8-Channel Universal Input Temperature & Signal ModuleNegotiableMOQ: 1 Combo

-

Honeywell FC-TSAOH-0220M (CCV 1.0) — Compact Process Control Module for Analog/Digital Signal ConditioningNegotiableMOQ: 1 Combo