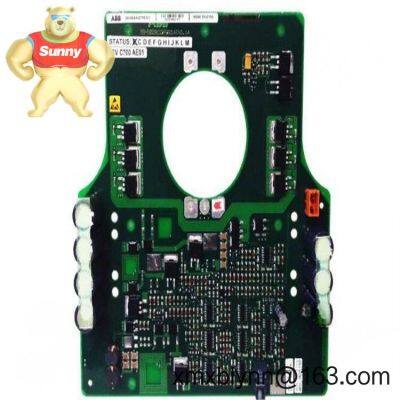

ABB 3BHB004027R0101 IGCT Gate Unit – Reliable Drive Control for Medium-voltage Power Stacks

The ABB 3BHB004027R0101 IGCT gate unit is designed to drive high-power IGCT devices in medium-voltage drives and converter stacks. From my experience, it’s typically found in ABB MV drive platforms where stable gate control, fiber-optic isolation, and robust protection logic are essential. If you’re maintaining aging assets or standardizing spares, this module helps keep critical compressors, pumps, and test benches running with minimal downtime.

IGCT-optimized gate driving – Provides the high-current, fast-rise gate pulses IGCTs require for low losses and reliable turn-off.

Fiber‑optic triggering and feedback – Typically uses optical links for galvanic isolation, noise immunity, and clean timing between control and power stages.

Integrated protection logic – Fault detection and interlocks appear to be built-in to protect the device during abnormal conditions.

Isolated low‑voltage power – Usually powered from a 24 VDC control supply with onboard isolation to the high‑energy stack environment.

Rugged construction – Conformal-coated PCB and industrial connectors suited to cabinet installations with vibration and electrical noise.

Service-friendly design – Clear status indication and modular connectors help maintenance teams swap units quickly.

Technical Specifications

Technical Specifications| Brand / Model | ABB 3BHB004027R0101 (IGCT Gate Unit) |

| Function | Gate driver for IGCT devices in MV drives and converters |

| Power Requirements | 24 VDC control supply (typical), isolated internally for gate drive circuits |

| Signal I/O Types | Fiber‑optic trigger/feedback; hardware fault/interlock signals (isolated) |

| Communication Interfaces | Optical links to the converter control; local status indicators |

| Operating Temperature | 0…55 °C (typical for cabinet-mounted drive electronics) |

| Form Factor / Installation | Power-stack mounted module; fixed with captive screws and dedicated harnessing |

| Typical Device Pairing | ABB IGCTs (e.g., 4.5 kV class, 5SHY series) in MV drive stacks |

| Compliance | CE; RoHS; manufacturer quality system typically ISO 9001 |

This gate unit is commonly deployed in medium-voltage variable frequency drives, multi-pulse converters, and power quality systems where IGCTs are preferred for efficiency and robustness. You might notice that plants with large synchronous or induction motors—compressors, pipeline pumps, induced-draft fans—often rely on this class of hardware.

Oil & Gas and Petrochemical MV drives (ACS-series platforms)

Metals, mining, and cement process lines with high-inertia loads

Power quality equipment such as SVC/STATCOM-type converters (IGCT-based)

Large test benches and grid-connected converters in R&D facilities

High reliability in harsh cabinets – Fiber isolation and robust protection logic reduce nuisance trips in electrically noisy rooms.

Compatibility with ABB MV stacks – In many cases drop-in for designated positions, minimizing retrofit effort.

Lower total downtime – Modular swap, straightforward fiber routing, and quick checks lead to faster turnaround.

Lifecycle support – Typically supported with repair/exchange programs, easing spares management for mature installations.

A maintenance lead at a steel mill told us their 3BHB004027R0101 swap took “about 20 minutes from lockout to power-up,” which seems to be consistent with what we see in most cabinets that are neatly wired and labeled.

Installation & MaintenanceCabinet environment – Mount within the specified MV power stack location; ensure ambient 0…55 °C and adequate ventilation around the heat paths.

Wiring and fibers – Route fiber‑optic cables with gentle bends; keep clear of high‑dv/dt busbars. Verify TX/RX polarity and cleanliness of ferrules.

Control power – Supply a clean 24 VDC control feed (typical). Use the dedicated isolated input specified for the gate unit.

Safety and ESD – Lockout/tagout the drive, discharge DC links, and handle the PCB with ESD protection. Never hot‑swap in energized stacks.

Routine checks – Inspect connectors and fibers quarterly, confirm tight fasteners, and review fault logs after trips. Firmware/config alignment with the host controller should be verified after any replacement.

Calibration – No routine calibration is usually needed, but timing/threshold checks may be part of annual preventive maintenance in critical lines.

CE compliant; RoHS-conform construction for electronic assemblies

Manufactured under ISO 9001 quality systems (typical for ABB facilities)

UL/CSA recognition often applies at the system level; treat this board as a component

Standard manufacturer warranty is commonly 12 months for replacement units

If you’re aligning spares, we usually recommend keeping at least one 3BHB004027R0101 per MV lineup plus a spare set of fiber jumpers. It helps teams respond quickly, especially during seasonal production peaks.

Send Inquiry to This Supplier

You May Also Like

-

ABB 07AI91 (GJR5251600R4202) – Analog Input Module for AC31/CS31 Process ControlNegotiableMOQ: 1 Combo

-

ABB 07BR61R1 (GJV3074376R1) – MasterBus 300 Repeater for Segment Isolation and Distance ExtensionNegotiableMOQ: 1 Combo

-

ABB 07DC91 (GJR5251400R0202) – Digital Control/communication Module for Legacy Procontrol/Advant 07-series SystemsNegotiableMOQ: 1 Combo

-

ABB 07EA90-SI (GJR5251200R0101) – System Interface Module for Advant Master S100 I/ONegotiableMOQ: 1 Combo

-

ABB 07KT94 (GJR5252100R3261) – Communication/Processor Module for Advant Controller 31 (AC31) SystemsNegotiableMOQ: 1 Combo

-

ABB 086318-002 / 086318-501 – Legacy I/O Termination Assembly for ABB Bailey INFI 90 / NET 90 CabinetsNegotiableMOQ: 1 Combo

-

ABB 086329-004 – Legacy DCS Module for ABB Bailey INFI 90 Maintenance and SparesNegotiableMOQ: 1 Combo

-

ABB 086339-501 – Field-Replaceable Industrial Control Module for Legacy ABB DCS RacksNegotiableMOQ: 1 Combo

-

ABB 086345-004 – Replacement Control Module for Legacy ABB Bailey DCS RacksNegotiableMOQ: 1 Combo

-

ABB 086348-001 – Legacy DCS Module for Bailey INFI 90 System SustainmentNegotiableMOQ: 1 Combo