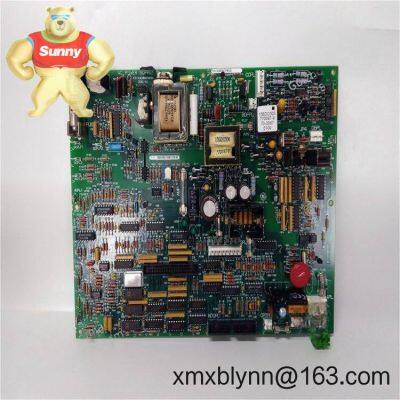

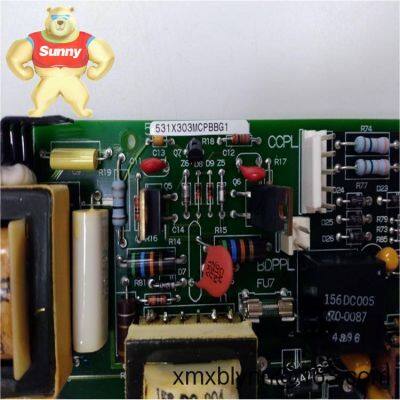

GE 531X303MCPBDG1 – MCPB Control Board for AC/DC Drive Platforms

The 531X303MCPBDG1, commonly called the MCPB board, is the central control PCB used in GE legacy AC/DC variable‑speed drive families (typically AC2000 and DC2000). You might notice it’s sometimes described as an “AC power card,” but in practice it functions as the drive’s control processor, coordinating speed/torque loops, I/O, and inter-board communications. It’s a practical drop‑in replacement when you’re restoring a downed line or extending the service life of installed GE drives.

Drive control core – Hosts the main control processor and firmware that manage speed/torque regulation and sequencing.

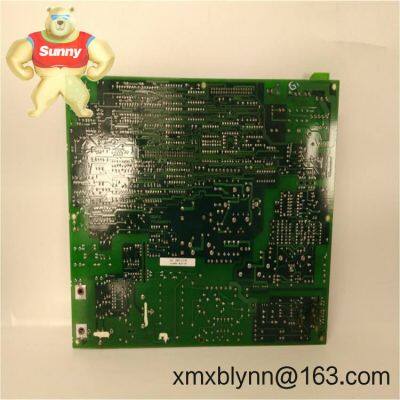

Backplane connectivity – Interfaces to companion 531X-series boards via multi‑pin and ribbon connectors for fast, reliable data exchange.

Mixed-signal handling – Supports typical analog references (e.g., ±10 V) and discrete I/O paths used by GE AC/DC drives.

Field-serviceable firmware – Socketed memory devices (in many cases) allow firmware updates or revision matching during replacements.

Form/fit compatibility – Designed as a direct replacement within GE AC2000/DC2000 card racks, minimizing rework and downtime.

Diagnostic indicators – Onboard LEDs (where fitted) provide quick health and status checks during commissioning and troubleshooting.

| Brand / Model | GE 531X303MCPBDG1 (MCPB) |

| Power Requirements | Supplied from drive’s internal PSU (typically +5 VDC and ±15 VDC rails) |

| Dimensions & Weight | Approx. 280 × 200 mm; ~0.5–0.7 kg (board-only, varies slightly by revision) |

| Operating Temperature | 0 to +55 °C typical (inside a ventilated cabinet) |

| Signal I/O Types | Mixed digital and analog via backplane/ribbon connectors; ±10 V references and isolated discretes commonly supported in-system |

| Communication Interfaces | Internal drive bus and board-to-board headers; optional service/programmer link depending on firmware/daughtercards |

| Installation Method | Rack/card-cage mount with standoffs; mates to multi‑pin connectors inside GE AC2000/DC2000 drives |

Application Fields

Application FieldsFrom my experience, this board shows up most often in heavy-duty production where downtime is expensive: steel and metals processing, pulp & paper, mining and aggregates, cement, marine winch/drives, and large HVAC or test stands. Anywhere a GE AC2000/DC2000 is governing motors, the MCPB is the brain that keeps loops tight and interlocks predictable.

A maintenance lead at a paper mill told me they swapped a failed MCPB with a matched 531X303MCPBDG1, restored parameters, and had the DC2000 back in service in under an hour—no drive re-engineering needed, which seems to be the real win here.

Advantages & ValueReliability – Proven in harsh industrial environments; conservative component selection and thermal profile when correctly ventilated.

Compatibility – Drop‑in fit for GE AC2000/DC2000 drives; avoids control retrofits or software rewrites.

Lifecycle extension – Keeps existing assets productive while you plan longer-term modernization at your pace.

Cost control – Typically a fraction of a full drive replacement; shorter outage windows reduce indirect losses.

Serviceability – Clear labeling, accessible connectors, and (in many cases) socketed firmware simplify field replacement.

Cabinet environment – Install in a clean, ventilated enclosure; maintain airflow and keep ambient within 0–55 °C.

ESD handling – Use a grounded wrist strap and antistatic mat; avoid touching IC pins or solder joints.

Wiring & seating – Power down, lockout/tagout, then seat the board firmly on standoffs; check all ribbon and backplane connections for full engagement.

Firmware alignment – Match firmware revisions/EPROM labels to the drive rating and option set; back up parameters before swap.

Routine checks – Inspect connectors for oxidation, clean dust with dry air, and verify grounding integrity during scheduled shutdowns.

Certifications – As part of GE drive systems, assemblies are typically CE and UL compliant when installed per OEM guidelines; RoHS status depends on production vintage.

Manufacturing – Produced under established GE quality systems (commonly ISO 9001 environments for drive assemblies).

Warranty – Standard manufacturer coverage is generally 12 months for new OEM supply; refurbished units are often provided with equivalent warranty by qualified distributors.

Note: If your documents label 531X303MCPBDG1 as an “AC power card,” it’s typically referencing its role within the AC drive assembly. Functionally, this MCPB is the control processor board. Share your drive rating and options if you’d like me to confirm firmware compatibility before you schedule a changeout.

Send Inquiry to This Supplier

You May Also Like

-

GE 531X307LTBAJG1 LAN Terminal Board – Reliable Field Wiring Interface for GE Drive NetworksNegotiableMOQ: 1 Combo

-

GE Multilin 750-P1-G1-S1-HI-A20-G – Feeder Protection Relay for Reliable MV/LV DistributionNegotiableMOQ: 1 Combo

-

GE PAC8000 8521-HC-MT – HART Maintenance Access for Remote Field I/ONegotiableMOQ: 1 Combo

-

GE LV5F30-NF – Low-voltage AC Drive for Reliable Motor Control in Pumps, Fans, and ConveyorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0 – Motor Management Relay for Reliable Three‑Phase Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-E-0 Motor Management Relay – Intelligent Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0-0 – Motor Management Relay for Reliable AC Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-F-E-0 – Motor Management Relay for Critical AC Motor Protection and ControlNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-M-0-0 – Motor Management Relay for Reliable Protection and MonitoringNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-R-0-0-0 – Motor Management Relay for Dependable Protection and RTD-based Thermal MonitoringNegotiableMOQ: 1 Combo