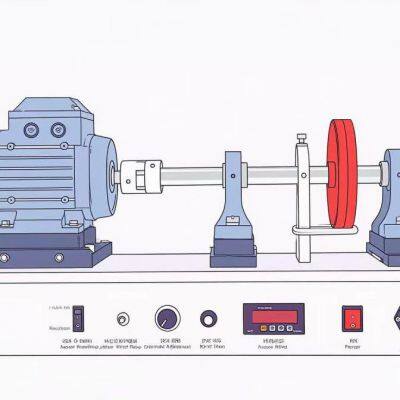

PT500 Drivetrain Diagnostics Simulator

≥1 Combos

- T/T L/C PayPal D/P Western Union Other

- 15 days

You May Like

Product Details

| Certification | ISO9001, CCC | Condition | New | |

| Customized | Customized | Warranty | 1 Year |

Product Description

An Ideal Simulator For Gearbox Reliability Studies

Product Description:

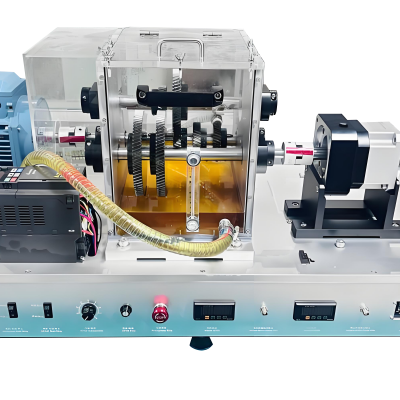

The P500 Multi-stage Gearbox Fault Simulator adopts ABB 1.5 kW three-phase asynchronous motor driven directly by coupling, with frequency converter to adjust the speed, and adjustable magnetic powder load to increase the test load on the test bench. Bearings with different types of faults can be selected to verify the frequency characteristics of bearing defects at different speeds. Fault gear testing, oil circulation system testing, rotor dynamic balance testing module, start stop testing, and shaft friction testing can also be conducted separately or in combination with various defects in a safe and controllable environment. As an innovative experimental platform for studying the fault characteristics of rotating machinery, it fully meets the extensive needs of teaching simulation and scientific research users.

Configuration:

The test bench is mainly composed of three-phase asynchronous motors, frequency converters, double support bearings, dynamic balancing rotor discs, oil circulation systems, shafts, two-stage transmission gear sets, planetary gearboxes, magnetic powder load torque adjustment mechanisms, shock-absorbing foundation bases, adjustable magnetic powder load brake components, etc.

Function:

•Fault bearing simulation: bearing inner race fault, bearing outer race fault, bearing rolling element fault, bearing cage fault, and comprehensive bearing fault.

•Gear fault simulation: missing teeth, broken teeth, wear, cracks.

•Simulation of planetary gear faults: missing gear, broken gear, wear, cracks.

•Oil circulation lubrication simulation and rotor dynamic balancing.

•Common mechanical failures: mechanical looseness, friction, and misalignment during testing.

•Identification of bearing fault frequency at different speeds.

•Test bench start stop test.

•Research on the vibration characteristics of the test bench under different torque loads.

Basic Technical Parameters:

Item | Description |

Drive motor power | ABB1.5kW,110V-220V |

Axis size | Diameter 30 mm, Chrome plated rust prevention |

Rolling bearing | PH206 deep groove ball rolling bearing, inner diameter 30mm, integrated bearing assembly with connected seats, convenient for replacing faulty bearings |

Type of faulty bearing | Inner race fault, outer race fault, cage fault, rolling element fault, comprehensive fault |

Powder brake | 0-50 N. M adjustment range |

Gear parameters | 2-level 3-axis spur gearbox, transmission ratio of 4.97:1, fault types: broken gear, wear, missing gear, cracks, convenient for switching meshing faulty gears |

Planetary gear box | Reduction ratio: 1:10, single pole transmission |

Rotation adjustment range | 0-1750rpm |

Production | Acrylic transparent cover protection, magnetic switch safety protection |

Size | 1680mm*530mm*510mm |

Contact Us

- Kunshan Hanjilong Measurement & Control Technology Co., Ltd.

- Contact nameCHAN Chat Now

- Phone86-512-57566265

- Addresskunshanjiandelu, Suzhou, Jiangsu

Product Categories

| Mechanical Fault Simulator | Bearing Fault Simulator | Drivetrain Diagnostics Simulator | motor fault diagnosis simulator |

| Prognostic Simulator |

New Products

-

BTS200 Bearing Prognostic Simulator

-

WFD800plus Wind Turbine Fault Test Station

-

PT500plus Rotor Parallel Shaft Gear Mechanism Test Bench

-

PT680 Generator Fault Simulation Test Bench

-

FRT1000 Rotor Dynamics Simulator

-

PT400MINI Machinery Fault Simulator Micro Version

-

PT300MiNi Portable Vibration Simulator

-

SAT300 Shaft Alignment Trainer

-

PT400pro Machine Vibration&Gearbox Simulator

-

PT500 Drive Train Diagnostics Simulator

-

PT3000-RH Turbine Unit Lubrication Monitoring System Experiment Station

-

Bearing Prognostic Simulator

-

PT400MINI BEARING GEARS FAULT SIMULATOR

-

Machinery Fault Simulation Machine Vibration Analysis Trainer

-

Shaft Alignment Trainer SAT300

-

PT500-DPS Gear Full Life Test Stand

-

FRT2000 High-speed Flexible Rotor Machinery Fault & Rotor Dynamics Simulator

-

PT300SAT Balancing Alignment Simulator

-

PT200 Vibration Analysis Training System Gearbox Prognostics Simulator

-

SAT500 Shaft Alignment Trainer Portable Vibration Simulator

-

PT100 Bearing Fault Simulator-alenian Machinery Fault Simulator

-

PT300 Machinery Fault Simulator–Lite

-

PT300PRO Machine Vibration Simulator

-

PT500mini Machinery Fault Simulator

Recommended Products

- PT400MINI BEARING GEARS FAULT SIMULATOR

- Bearing Prognostic Simulator

- PT3000-RH Turbine Unit Lubrication Monitoring System Experiment Station

- PT500 Drive Train Diagnostics Simulator

- PT700 Machinery Fault & Rotor Dynamics Simulator

- PT800 Machinery Fault Simulator-Magnum

- PT900 Dual-rotor System Fault Simulator

- PT500pro Machine Vibration & Gearbox Simulator

- BTS100 Bearing Prognostic Simulator

- PT5000 Turbine Sliding Bearing System Simulation Test Bed

- WFD1000 Wind-turbine Simulator

- PT580 Water Pump Test Bench

Find Similar Products By Category

- Office Supplies > Demonstrational & Teaching Utensil > Mechatronics Training Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

CHAN

Hi there! Welcome to my shop. Let me know if you have any questions.

CHAN

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile