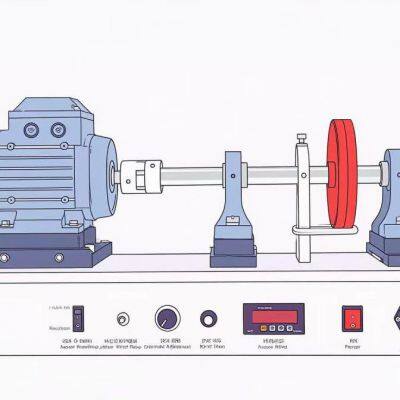

PT5000 Turbine Sliding Bearing System Simulation Test Bed

≥1 Combos

- T/T L/C PayPal D/P Western Union Other

- 15 days

You May Like

Product Details

| Certification | ISO9001, CCC | Condition | New | |

| Customized | Customized | Warranty | 1 Year |

Product Description

Simulador de fallas de equilibrio y rodamientos

Product Description:

The sliding bearing simulation test bench is a scaled down model similar to a steam turbine generator in a power plant. This is an experimental device that enables you to gain practical experience on the dynamic behavior of turbine rotors and the oil film phenomenon of sliding bearings, and to study vibration control methods.

This simulation test bench is a model that simulates a two-stage turbine, namely a low-pressure (low pressure) turbine and an IP (medium pressure) turbine. There are 8 blades on each side of each rotor stage, for a total of 16 blades. The LP part is resonance, which can generate up to the second critical velocity mode. By using an electric motor instead of a turbine generator, resonance can be clearly identified by performing a waterfall diagram of rotor vibration during start stop testing. By applying different clearances of bearings or shapes of sliding bearings, we study under what conditions oil film vortex and oil film oscillation occur, and adjust the lubricating oil pressure, temperature, and preload force appropriately to simulate and reproduce oil film vortex and oil film oscillation, and find conditions to control oil film vortex and oil film oscillation.

Similar to a steam turbine, a simulation test bench equipped with a long axis rotor can use sliding bearings to reproduce all kinds of vibration phenomena occurring in the rotor. You can test the mechanical vibration phenomena that occur in the rotor, such as unbalance, shaft misalignment, blade friction and seal friction, looseness, and fluid phenomena. The series is specifically designed to test oil film phenomena based on the design and operating conditions of sliding bearings. Installing multiple rotor discs instead of turbine blades on the shaft can produce the second mode (the second critical speed), which can reproduce the fluid phenomenon (oil whirl and oil oscillation) of sliding bearings. Oil film vortex and oil film oscillation are important unstable phenomena in rotor supported oil film bearings. It is necessary to adjust the bearing load (rotor disk weight), bearing clearance (bearing seat selection), and oil pressure (oil supply valve adjustment) appropriately. If selected, oil film vortex and oil film oscillation can be simulated, and the waterfall diagram can clearly identify the characteristic signals of oil film vortex and oil film oscillation vibration.

One of the key concepts in rotor dynamics is to predict the behavior of the rotor by identifying key and high points. Use a proximity eddy current probe installed in a 90 ° direction and a key speed phase to analyze the axis trajectory based on the phase relationship between these two points.

Configuration:

Compact, all components are installed on the base plate.

Shaft: 30mm diameter, 1200mm long modulated straight steel shaft.

1.5KW variable frequency drive with built-in multifunctional programmable controller.

Motor: 3-phase 1.5KW, equipped with a power plug for easy installation and disassembly.

Speed display, outputting 1 pulse per rotation to simulate TTL signal.

Two bearing seats: built-in sliding bearings, two holes close to eddy current sensors, and one hole for installing a temperature sensor.

Rolling bearings can be used to replace sliding bearing designs.

90 ° installation of eddy current sensors (4 proximity eddy current sensors, 1 key direction sensor).

Function:

The rotor shaft is designed specifically for fluid sliding bearing rotor dynamics simulation.

Study the optimal equipment for rotor dynamics with various sliding bearings.

Lubricating oil system: pressure and temperature are controllable.

Install proximity eddy current probes in each bearing seat.

Separate the bracket bearing seat for easy replacement of the sliding bearing seat.

Provide various sliding bearing seats to study oil film phenomena.

By installing the jack screws, it is easy to align the shaft.

By installing a dial gauge, it is easy to return to normal operating conditions after misalignment testing.

Basic Technical Parameters:

| electrical machinery | 3-phase 3.7 kW 2-pole 220/380V 50/60Hz AC |

| frequency converter | Delta VVVF driver VFD300 380V3.7 kW 3-phase input |

| speed range | Variable speed range of 100-7000rpm |

| display instrument | RPM, Oil pressure, bearing temperature, motor current 7-segment LED display screen, maximum 20/second. |

| Output terminal | Displacement output: 8, phase, temperature, pressure, speed output: 1 pulse/rotation, 12V TTL, RPM DC output |

| sliding bearing | Circular, length: 30 millimeters and circular, length: 30 millimeters and diameter: 40 millimeters. 40.1, 40.25, 40.5 Mm, 40.1-40.5mm elliptical, 40.1mm pit type bearing seat. |

| Oil circulation lubrication system | Pump, pressure gauge, fuel tank, check valve, temperature sensor |

| Rotor disk | Rotor disc diameter, 460-200mm, 16, 36, 24 or 18-M8 holes, used for unbalance and on-site balancing, Used for imbalance and on-site balancing |

| size | 3200 x 1000 x 1300 mm |

Contact Us

- Kunshan Hanjilong Measurement & Control Technology Co., Ltd.

- Contact nameCHAN Chat Now

- Phone86-512-57566265

- Addresskunshanjiandelu, Suzhou, Jiangsu

Product Categories

| Mechanical Fault Simulator | Bearing Fault Simulator | Drivetrain Diagnostics Simulator | motor fault diagnosis simulator |

| Prognostic Simulator |

New Products

-

WFD800plus Wind Turbine Fault Test Station

-

PT500plus Rotor Parallel Shaft Gear Mechanism Test Bench

-

PT680 Generator Fault Simulation Test Bench

-

FRT1000 Rotor Dynamics Simulator

-

PT400MINI Machinery Fault Simulator Micro Version

-

PT300MiNi Portable Vibration Simulator

-

SAT300 Shaft Alignment Trainer

-

PT400pro Machine Vibration&Gearbox Simulator

-

PT500 Drive Train Diagnostics Simulator

-

PT3000-RH Turbine Unit Lubrication Monitoring System Experiment Station

-

Bearing Prognostic Simulator

-

PT400MINI BEARING GEARS FAULT SIMULATOR

-

Machinery Fault Simulation Machine Vibration Analysis Trainer

-

Shaft Alignment Trainer SAT300

-

PT500-DPS Gear Full Life Test Stand

-

FRT2000 High-speed Flexible Rotor Machinery Fault & Rotor Dynamics Simulator

-

PT300SAT Balancing Alignment Simulator

-

PT200 Vibration Analysis Training System Gearbox Prognostics Simulator

Recommended Products

- PT400MINI BEARING GEARS FAULT SIMULATOR

- Bearing Prognostic Simulator

- PT3000-RH Turbine Unit Lubrication Monitoring System Experiment Station

- PT500 Drive Train Diagnostics Simulator

- PT700 Machinery Fault & Rotor Dynamics Simulator

- PT800 Machinery Fault Simulator-Magnum

- PT900 Dual-rotor System Fault Simulator

- PT500pro Machine Vibration & Gearbox Simulator

- BTS100 Bearing Prognostic Simulator

- PT500 Drivetrain Diagnostics Simulator

- WFD1000 Wind-turbine Simulator

- PT580 Water Pump Test Bench

Find Similar Products By Category

- Office Supplies > Demonstrational & Teaching Utensil > Mechatronics Training Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

CHAN

Hi there! Welcome to my shop. Let me know if you have any questions.

CHAN

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile