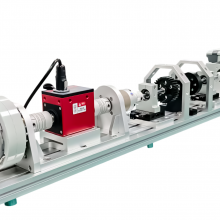

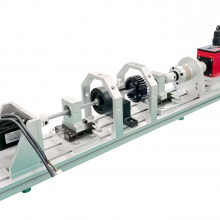

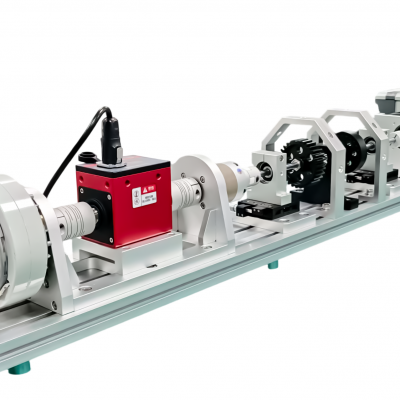

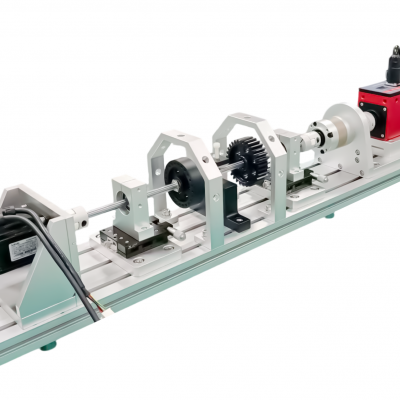

PT200 Vibration Analysis Training System Gearbox Prognostics Simulator

VALENIAN-PT200 Vibration Analysis Training System is a multi-functional mechanical fault simulation experimental equipment developed for rotor dynamics of rotating machinery and related scientific research projects in colleges and universities as well as research institutes. This test bench features a simple structure, convenient assembly and disassembly, easy operation and stable performance. It can be flexibly equipped with sensors for measuring mechanical parameters such as vibration, rotational speed, noise and displacement. It can also simulate the vibration state of rotating machinery during transient processes of acceleration and deceleration as well as steady-state operation conditions, and various common faults of rotating machinery, such as rotor dynamic balance test, bearing fault test, rotor misalignment test and mechanical looseness test. In addition, it can be optionally equipped with faulty planetary gear components and conduct fault feature analysis for various common rotating machinery faults.

It can be used with multi-channel data acquisition instruments and analysis software developed by Valenian Company to form a multi-purpose and comprehensive experimental system platform, providing researchers engaged in rotor dynamics and related rotating machinery research projects with a good experimental analysis environment and stable fault signal output.

Experimental research contents:

Carry out experiments to simulate common rotor mechanical faults: such as shaft misalignment, rotor unbalance, rotor rub-impact, and looseness of mechanical foundation.

Research on rolling bearing faults: different fault forms of supporting bearings, such as bearing inner ring fault, bearing outer ring fault, bearing cage fault, bearing rolling element fault, bearing comprehensive fault, etc.

Research on planetary gearbox faults: faults of sun gear, planetary gear and large gear ring, with fault types including missing tooth, wear, broken tooth and crack.

Simulation of different working conditions: vibration characteristics of bearings when the motor is in acceleration and deceleration states, and performance of vibration data of faulty bearings under different load states.

Single fault or multiple faults can be introduced simultaneously to study their mutual coupling effects.

Learn and carry out non-contact eddy current sensor measurement technology.

Research on fault signal feature recognition and signal feature processing can be conducted.

Carry out torque loading experiments on rotor shafting to study the influence of torque load on the vibration of bearings and rotors.

Supporting bearing inner ring fault, bearing outer ring fault, bearing cage fault, bearing rolling element fault, and bearing comprehensive fault.

Planetary gearbox fault research: faults of sun gear, planetary gear, and large gear ring, with fault types including missing tooth, wear, broken tooth, and crack.

The test bench system is mainly composed of a high-strength aluminum profile platform, a 0.4KW servo drive motor, a motor mounting bracket, a 10MM straight steel shaft, 6300 deep groove ball rolling bearings, an adjustable eccentric bearing seat, a speed measuring gear plate, a dynamic balance rotor disk, a coupling, a planetary gearbox, a visual torque and speed meter, a portable electrical control box unit, etc.

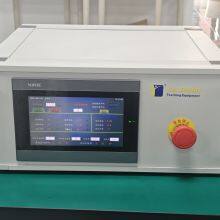

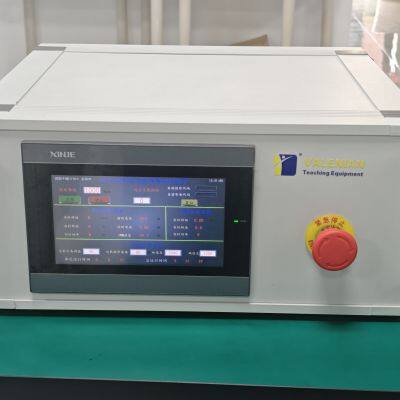

Servo motor, servo driver, 7-inch touch screen human-machine interface unit, PLC, analog module, heat dissipation unit, loader control unit, switching power supply module, and rotor control system box (high-strength aluminum alloy).

Send Inquiry to This Supplier

You May Also Like

-

PT400 Vibration Demo Equipment Gear Fault SimulatorUS$ 3599MOQ: 1 Combo

-

PT650 Motor Fault Diagnosis SimulatorUS$ 3999MOQ: 1 Combo

-

PT560 Fluid Pump Valve Module Test BenchUS$ 3980MOQ: 1 Combo

-

PT580 Water Pump Test BenchUS$ 3699MOQ: 1 Combo

-

WFD1000 Wind-turbine SimulatorUS$ 2699MOQ: 1 Combo

-

PT500 Drivetrain Diagnostics SimulatorUS$ 2999MOQ: 1 Combo

-

PT5000 Turbine Sliding Bearing System Simulation Test BedUS$ 2599MOQ: 1 Combo

-

BTS100 Bearing Prognostic SimulatorUS$ 3800MOQ: 1 Combo

-

PT500pro Machine Vibration & Gearbox SimulatorUS$ 3980MOQ: 1 Combo

-

PT900 Dual-rotor System Fault SimulatorUS$ 3800MOQ: 1 Combo