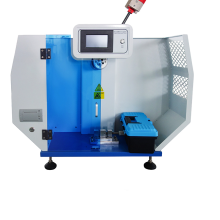

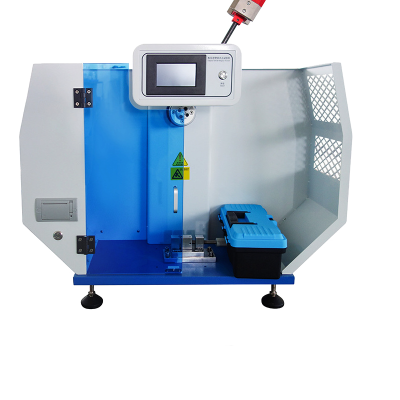

metal Material Impact Resistance Test Testing Machine Specification:

Capacity | Simply Supported Beams:7.5, 15, 25, 50J | Izod Beams:2.75J、5.5J |

| Impact velocity | 3.5m/s, 2.9m/s or specified | |

| Test angle | 150° | |

| Impact blade angle | 30°±l° | |

| Distance between jaw and support line | 60mm, 70 mm,95mm | |

| Blade filleted radius | R=2±0.5mm | R=0.8mm±0.2mm |

| Display | LCD Touch Screen | |

| Model | GC-XJL-5/5.5D | |

| Power | AC220V±10%, 50/60Hz | |

I. Core Standards for Impact Testing of Metals

ASTM E23

Standard notched specimen (Charpy V-type or U-type), the size of 10 × 10 × 55 mm, the test energy range is usually 150-400 J. The notched specimen can be used for impact testing of carbon steel, alloy steel, cast steel and other materials at low or high temperatures.

It is suitable for low, normal or high temperature impact testing of carbon steel, alloy steel, cast iron and other materials.

ISO 148-1

International standard, the specimen size is similar to ASTM E23, but some test parameters (such as pendulum speed) are slightly different.

GB/T 229

Chinese national standard, compatible with the Charpy impact test for metal materials.

Second, the core components of the metal impact resistance testing machine

1. Equipment Module

Module Technical Requirements

Pendulum system - Energy range: 150-500 J (can be expanded to higher energy).

- Pendulum pre-lift angle ≥ 150 °, impact speed of 5-5.5 m / s.

Specimen Fixture - Simple beam support (span 40mm), notched back to the pendulum.

- Automatic centering device ensures accurate positioning of the specimen.

Environmental control - optional high and low temperature chamber (-196℃~+200℃), liquid nitrogen cooling or electric heating.

- Temperature uniformity ±1℃ (low temperature test).

Data Acquisition System - Microcomputer control, touch screen display impact energy, temperature and other parameters.

- Automatic calculation of impact absorption energy (KV/J), support data export (Excel/PDF).

Safety Protection - Fully enclosed protective cover + safety interlocking device.

- Emergency brake button and debris collection device.

Third, the test process (ASTM E23 as an example)

Specimen preparation:

According to the standard processing V-notch specimen (notch depth of 2mm, the bottom radius of 0.25mm), the surface without scratches.

Low-temperature test specimens need to be cooled in liquid nitrogen or alcohol bath and insulation (such as -40 ℃ insulation for 10 minutes).

Equipment Calibration:

Calibrate the energy scale using a standard specimen (e.g., NIST traceable steel sample) with an error of ≤±1%.

Check the no-load energy loss of the pendulum (should be ≤ 0.5%).

Test Execution:

Place the specimen horizontally in the fixture with the notch back to the direction of the pendulum impact.

Release the pendulum to impact the specimen and record the fracture energy and fracture morphology.

Result Analysis:

Impact absorbed energy (KV): directly read the microcomputer display value (unit: Joule J).

Fracture morphology: Evaluate the ratio of fibrous (ductile) to crystalline (brittle) fracture.

IV. Maintenance and calibration

1.

Routine maintenance:

Regularly lubricate the pendulum bearings and guide rails and clean the specimen fixture.

◦

Check the shield interlock function to ensure that the safety device is effective.

2.

Calibration requirements:

Verify energy accuracy (error ≤ ±1%) with a standard specimen every month.

Commission third party calibration (ISO 17025 standard) annually, including energy sensors and temperature probes.

V. Precautions

Specimen processing:

Notches must be machined with a special milling cutter to avoid burrs or cracks (otherwise data deviations are significant).

Low temperature specimen transfer needs to be rapid (≤ 5 seconds) to prevent temperature regain.

Safe operation:

Close the guard during testing and prohibit operation within the swinging range of the pendulum.

Freeze-proof gloves and goggles are required for liquid nitrogen cryogenic testing.

Send Inquiry to This Supplier

You May Also Like

-

High Sensitivity 0.001 Differential Scanning Calorimeter DSC With Cooling SystemUS$ 6000 - 8000MOQ: 1 Set

-

Differential Scanning Calorimeter (DSC) With Liquid Nitrogen CoolingUS$ 6000 - 8000MOQ: 1 Set

-

Differential Scanning Calorimeter (DSC) With Liquid Nitrogen CoolingUS$ 6000 - 8000MOQ: 1 Set

-

Type Differential Scanning Calorimeter for Polymer MaterialUS$ 6000 - 8000MOQ: 1 Set

-

Thermal Gravimetric Analyzer Dsc Differential Scanning CalorimeterUS$ 6000 - 8000MOQ: 1 Set

-

Diamond Dsc Differential Scanning CalorimeterUS$ 6000 - 8000MOQ: 1 Set

-

ISO Laboratory 500C TGA DSC STA Thermal Analyzer DSC Differential Scanning Calorimeter PriceUS$ 6000 - 8000MOQ: 1 Set

-

Differential Scanning Calorimeter Calorimetry Price Industrial Instrument CalorimeterUS$ 6000 - 8000MOQ: 1 Set

-

Computerized Double Column Tensile Testing MachineUS$ 3999 - 9999MOQ: 1 Set

-

Computer Control Tensile Test Equipment Universal Tensile Strength Testing MachineUS$ 1000 - 3500MOQ: 1 Set