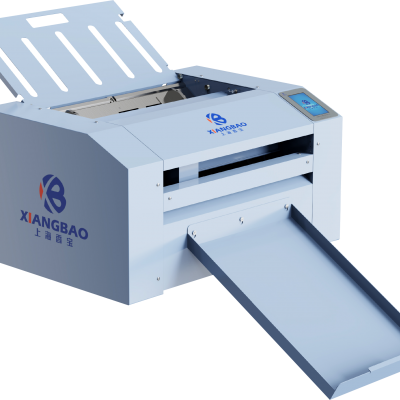

Shanghai Xiangbao Intelligent Digital Die Cutting Machine

WIFI remote control can support the synchronous transmission operation of one computer connected to multiple machines, and can be connected to up to 100 machines at the same time. It can also be sent remotely with multiple computers for one machine. Each computer can send and operate the machine separately without the need for a special computer to operate. For graphic advertising stores, the machine location can be placed at will, and remotely sent by WIFI, and the machine does not need to be connected to the machine with traditional USB data cable, making it more convenient to use. You can also use a USB drive to operate offline without using a network or USB cable. Through the printer, marking points and patterns are printed out, and the machine automatically feeds paper, automatically positions, automatically cuts, and automatically outputs paper, realizing automatic operation.

The paper feed size 320X700mm is suitable for a wide range of paper, high-pressure cutting and high-definition camera scanning, which is suitable for a wider range of materials and has better paper jam cutting effect. The three modes of transmission meet the use of different environments. The machine supports six languages and has a wider range of operational applicability.

The operation software adopts the CDR+ plug-in mode, and generates corner marking points with one click. The plug-in automatically generates marking points according to the size and content of the paper. It can automatically generate a QR code. The machine automatically recognizes the file cutting according to the QR code. It can cut files of different contents at the same time, and keep scanning and cutting much more accurately. Reasonably design marking points, with a minimum margin of 5mm, saving maximum cutting material, and automatically adjust the position of marking points according to the typesetting and printing needs. The scanning method adopts camera positioning, with a wider scanning range and a higher success rate. It can identify more than ten different materials, such as: coated paper self-adhesive, kraft paper self-adhesive, PVC self-adhesive, fragile self-adhesive, etc., which greatly increases the recognition rate and cutting accuracy, making scanning faster.

The two sides of the platform use double-linked centered paper feeding, and the thickened baffle is positioned simultaneously. The baffle on both sides of the paper feeding for a long time will not loosen, and the paper blocking is more stable, ensuring that the paper feeding will not tilt, and cutting is more accurate. The centered paper feeding ensures the consistency of pressure on both sides.

Adopt a dual paper feed system, with two wheels of paper feeding in the center, and two wheels of auxiliary paper feeding. The feed pressure can be adjusted freely to meet the smooth paper removal of paper with different thicknesses. The machine adopts anti-double-shot programming to effectively reduce the phenomenon of double-shots. Increase the large cowhide feeding wheel to increase friction, avoid double sheets, and ensure smooth paper feeding. Heavy Dual Dual Row Paper Pressing Roller, 20 springs have a pressure, a greater pressure, a more stable paper pressing, and paper removal is not easy to tilt. It realizes continuous cutting of single sheets and stable paper feeding. There is no need to manually operate the paper loading sheets and can work without being on duty. The paper feeding has been upgraded to an enlarged paper tray to ensure smoother paper loading and smoother paper handling. It can place about 150 sheets of paper at a time. Reduce the number of paper loading and save labor. Increase and widen drawer-type paper bins, design user-friendly paper pickup methods, to save space

For different materials, the brightness of LED lights can be adjusted at will to improve the scanning success rate. Effectively protect the eyes when watching the cut effect. High-performance precision structure, built-in automatic air suction device, the paper is smoother, ensuring more uniform paper pressure and more accurate cutting.

Production parameters:

Model :Shanghai Xiangbao Intelligent Die Cutting MachineDisplay :Method Color Touch Screen

Cutting Width :320mm ;Paper Feed Length: 700mm

Cutting Accuracy: 0.01mm

Speed :800mm/s

Pressure : 160 (approximately 2000g)

Voltage: Support 110V/220V

Paper Loading Capacity :150 sheets

Transmission Method :WIFI, USB Disk, USB Data Cable

Operation Software :Ai (CS6 2018/2019) CorelDRAW (x4-x8, 2017-2019)

Computer System :Windows 7-10, Plug-in does not support Apple system

Net weight: 61KG

with wooden box: 64 kg

Expanded size :Length 1040mm*Width 710mm*Height 530mm

Unexpanded size :Length 520mm*Width 710mm*Height 390mm

Packaging box size : 840*630*620mm

Send Inquiry to This Supplier

You May Also Like

-

Shanghai Xiangbao 7553 Multi-function Digital Proofing Die Cutting MachineNegotiableMOQ: 1 Piece

-

Shanghai Xiangbao XB-1007 Automatic High-speed Flat-plate Die Cutting MachineNegotiableMOQ: 1 Piece

-

Shanghai Xiangbao XB-ZN2501 High-speed Die Cutting MachineNegotiableMOQ: 1 Piece

-

Shanghai Xiangbao XB-V58T Flagship Model Laminating MachineUS$ 492 - 971MOQ: 1 Unit

-

Shanghai Xiangbao XB-100D Automatic Folding and Stitching MachineUS$ 2225 - 2788MOQ: 1 Piece

-

Shanghai Xiangbao XB-S31T Ultra-Quiet StitcherUS$ 328 - 540MOQ: 1 Unit

-

Shanghai Xiangbao XB-AT900EP Flagship-version Electric Paper CutterUS$ 1239 - 1380MOQ: 1 Piece

-

Shanghai Horizon XB-AR1000H Flagship Version Automatic Glue Binding MachineUS$ 5183 - 5605MOQ: 1 Piece

-

Shanghai Xiangbao XB-V68T Heavy-duty Hydraulic Laminating MachineUS$ 1943 - 2225MOQ: 1 Piece

-

Shanghai Xiangbao XB-AT900EP Heavy Duty Electric Paper Cutting MachineUS$ 1661 - 2225MOQ: 1 Piece