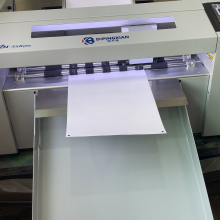

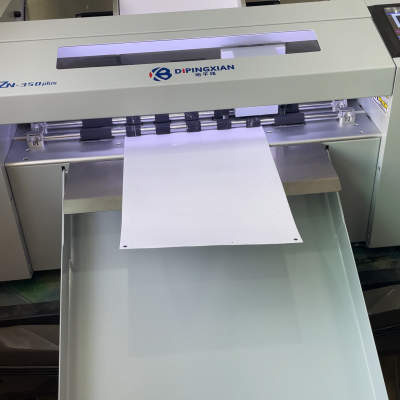

Shanghai Xiangbao XB-ZN350 Ultra-high Speed Die-cutting Machine

Machine features: Currently China's (fastest) die-cutter

High-performance servo motor: ZN-350 X and Y are controlled by high-precision overspeed servo motors, which are faster, have higher accuracy, smaller sound, and have better stability. The control is more accurate. The overspeed servo motor realizes closed-loop control of position, speed and torque; avoids the problem of stepping motor losing steps during long-term operation. It is suitable for occasions where high-speed response requirements are required.

High stability beam ZN-350 adopts a high-precision beam design, referring to the Japanese Tiewang cross beam running structure. At the same time, the car adopts a lightweight structure of all aluminum and is fixed with eight-point support. The support points are supported by steel bars. It is difficult to deform and wear for a long time. The car uses Japanese NSK bearings to run. It is durable. The high-precision beam greatly improves the operating accuracy and stability of the machine, ensuring that the machine does not shake during high-speed operation and has better stability.

High-precision car ZN-350 cuts are controlled by a voice coil motor (voice coil motor). The voice coil motor has high precision and high speed, and is faster response speed. It is durable, wear-resistant and long service life. In this way, the cutting material has more precise and stable cutting force control, and is not easy to have shallow depth. The inconsistency ensures the pass rate of the finished product, effectively eliminates the phenomenon of waste of materials, and realizes unattended.

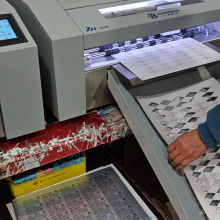

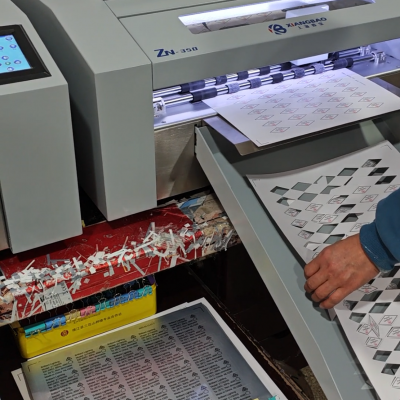

High-resolution CCD camera ZN-350 uses a high-resolution CCD high-definition camera, which is used to accurately detect marking points (corners are compatible with dots), and can accurately detect marking points on color and reflective materials. It can be typesetted according to customer needs, thereby saving materials and reducing production costs. It can also support lighting brightness adjustment. The light brightness can be adjusted freely according to different materials to increase the accuracy of recognition. The camera can scan 4 marking points in less than 3 seconds, saving production time, improving work efficiency, and reducing costs.

QR code system ZN-350 can automatically read the QR code printed on the material. You only need to add the QR code when making the file and print out the QR code file. The machine will automatically read the QR code file and accurately cut it. This function can effectively reduce the time to find files and improve work efficiency. In addition, ZN-350 can also support network QR code reading. When making QR code files, save the QR code file to the specified computer folder. Select QR code to read in the plug-in. The machine will automatically read the specified QR code folder and automatically find the QR code for accurate cutting. This will improve work efficiency.

Intelligent software: The ZN-350 operation software adopts CDR and AI+ plug-in mode, generates corner lines and dot marking points with one click, and double marking points are recognized. The plug-in automatically generates marking points based on the paper size and content, typed in one click, and generates outlines with one click. The software automatically optimizes the cutting path, which is convenient for user operations, is simple and fast. It improves user work efficiency. At the same time, the machine optimizes the paper pickup method. When the paper pickup fails, the paper will be automatically returned. The paper feed will be repeated three times again to ensure the smoothness of the paper feed.

Multiple transmissions: The ZN-350 operation software adopts remote control of network cable, WIF1, USB disk, and USB data cable. It can support one computer to connect to multiple machines to synchronously send operations. Up to 100 machines can be connected to one machine at the same time. One machine can use multiple computers to send remotely. Each computer can send the machine separately, without the need for a special computer to operate. For graphic advertising stores, the machine location can be placed at will, and remotely sent by network ports and WIFI, and does not use traditional USB data cables to connect the machine, making it more convenient to use. You can also use a USB drive to operate offline without using a network or USB cable. Through the printer, marking points and patterns are printed out, and the machine automatically feeds paper, automatically positions, automatically cuts, and automatically outputs paper, realizing automatic operation.

Humanized function design: The ZN-350 has a count skip recording function. When the user puts more materials into the machine for cutting, the user does not need to look at the machine. There will be counts after the machine is cut. If there is a material that fails to scan the material in the middle, the machine will automatically spit out the material and record the number of scans in the settings. The user only needs to check the number of skip parts after the machine is cut, to determine whether there is any problem with the cutting, which saves customers time and realizes unmanned duty of the machine. Improve work efficiency

High-quality materials: The ZN-350 motherboard chip uses ST imported chip, which has high performance, low power consumption, durability and very good stability. X and Y running belts are made of imported Pioneer belts, with good transmission stability, higher accuracy, durability and very strong stability. The paper feed adopts a thickened barrier gauge with a thickness of 9 mm. In the case of large batches of paper removal, the barrier is not easy to loosen, and the paper is not easy to skew and smooth.

Easy to repair: The ZN-350 has three sets of sensors, using Sharp sensors, which have high sensing sensitivity, long life and the state of the sensor can be observed in the machine settings. When problems arise, it is convenient for users to discover problems and repair them in time.

Technical parameters:

Model: XB-ZN350

Display mode: 4-inch color touch screen

Material cutting range: Width: 200-350mm.200-800mm (to increase the length, you need to extend the paper tray yourself)

Mechanical accuracy: 0.01254mm

Fastest cutting speed: 1600mm/s

Maximum pressure: 1000g

Minimum cutting pattern: 5mm diameter circle

The thickest material that can be cut is 350g

Feeding time: 2 seconds

Transmission method: network cable, WIF, U disk, USB data cable

Paper capacity: 180 sheets (0.2 thickness)

Language: Chinese, English, Spanish, Danish, Turkish, Hungarian

Voltage: Support 110V/220V (automatic voltage conversion)

Operating software: AI (CS6-2023), coreidraw (x4-x8.2017-2023) (continuously updated)

Operating environment: Temperature: 10°to 35°

Humidity: 35 to 75% RH

Computer system: Windows7-10

Dimensions (mm): Non-expanded size: length 480mm width 770 height 340 (length x width x height)

Expanded size: length 1160mm width 770 height 500

Weight: 55KG (volume weight converted to 62 kg)

Packing size: length 570mm width 870mm height 600mm

Send Inquiry to This Supplier

You May Also Like

-

Shanghai Xiangbao XB-ZN2501 High-speed Die Cutting MachineNegotiableMOQ: 1 Piece

-

Shanghai Xiangbao Intelligent Digital Die Cutting MachineUS$ 1380 - 2200MOQ: 1 Piece

-

Shanghai Horizon XB-ZN360plus Double-heads Fully Automatic Die Cutting MachineNegotiableMOQ: 1 Piece

-

Shanghai Xiangbao XB-AR9000H Flagship Edition Binding MachineUS$ 3070 - 3352MOQ: 1 Piece

-

Shanghai Xiangbao XB-AT552-09EP Dual Hydraulic Heavy Duty Paper Cutting Machine (with Blowing Beads)NegotiableMOQ: 1 Piece

-

Shanghai Xiangbao XB-V80TF Hydraulic Semi-automatic Laminating MachineNegotiableMOQ: 1 Piece

-

Shanghai Xiangbao XB-AT5810EP Hydraulic Paper Cutting MachineUS$ 2788 - 3352MOQ: 1 Piece

-

Shanghai Horizon XB-Z50TF Fully Automatic Laminating Machine (reduce Manual and Improve Efficiency)US$ 2788 - 3352MOQ: 1 Piece

-

Shanghai Xiangbao XB-AT551-09EP Ultimate Edition Hydraulic Paper CutterUS$ 2358 - 2828MOQ: 1 Piece

-

Shanghai Xiangbao XB-AR10000H Heavy Duty Glue Binding MachineUS$ 4198 - 5605MOQ: 1 Piece