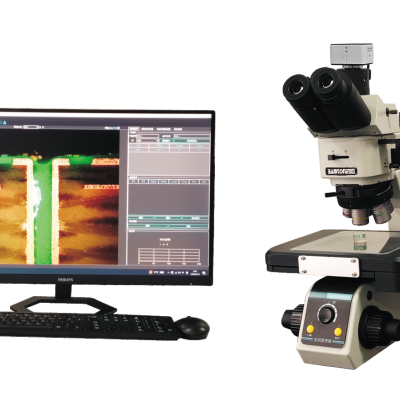

1、Product Introduction:

The metallographic microscope system integrates traditional optical microscopes with computers (digital cameras) through photoelectric conversion. It not only enables microscopic observation through eyepieces but also allows real-time dynamic image viewing on computer screens. The computerized metallographic microscope further supports editing, saving, and printing of required images.

2、applied range:

Bamtone Technology's microscope solutions make industrial inspection easier, more convenient, and more efficient. When these microscopes are successfully integrated into production lines, addressing ergonomic concerns like operational comfort and wafer safety becomes crucial – areas we focus on resolving. We provide innovative concepts, solutions, and technical support for industries including semiconductor wafers, flat-panel displays, and electronic devices. The systems' functions can be freely configured to meet professional requirements in industrial inspection and metallographic analysis, with broad applications ranging from medical institutions, laboratories, research institutes, and universities for observation, teaching, research, clinical trials, and routine medical testing, to factories and laboratories for material analysis and identification.

3、Product features and characteristics:

1. All optical components are specially treated and coated with special film layers.

2. Flexible and compact structure, suitable for various environments of microscopic observation.

3. Professional metallographic objective lens, high magnification objective lens adopts semi-reducing technology.

4. Clear, sharp and high contrast images can be obtained under various observation methods.

5. The standard reflective LED light source can be adjusted to perform surface observation (reflection observation) or backlight observation (transmission observation).

6. The compact structure design is selected, the appearance is grand and stable, and the operation is more flexible.

7. It integrates various observation functions such as bright field, dark field, polarization and DIC differential interference, which can be selected according to practical applications.

8. High eye point large field of view flat field of view eyepiece, refractive power can be adjusted.

9. The field of view is more flat and wide, with clear and bright edges that ensure a comfortable visual experience. It provides a broader observation range across platforms, enhancing work efficiency. The wider diopter adjustment range accommodates diverse user needs.

10. Other magnification and field of view can be selected, and pointers, micrometers and adjustable vision can be added according to different needs.

11. The polarization system consists of polarizer plates and analyzer plates, designed for optical detection. In semiconductor and PCB inspection processes, it effectively eliminates stray light to enhance image clarity. The 360-degree rotating analyzer allows convenient observation of specimens under various polarization angles without moving the sample.

12. On the basis of orthogonal polarization, DIC differential interference contrast observation can be carried out by inserting DlC prism. DIC technology can make the small height difference on the surface of the object produce a distinct relief effect and greatly improve the image contrast.

13. Using high-performance differential interference components, the fine height difference that cannot be detected under bright field observation can be converted into high contrast light and shadow difference and expressed in the form of three-dimensional relief. It is widely used in LCD conductive particles, precision disk surface scratch detection and other fields.

14. Can measure the size of any geometric figure on a plane (angle, length, diameter, radius, distance from a point to a line, ratio of two circles, etc.).

15. Various geometric dimensions can be annotated on the actual workpiece in real time image.

16. Take a picture: Take a picture of the object, including the size indicated.

17. Image stitching: Two or more images taken after shooting can be stitched into a single panoramic image.

18. Report output: The measurement results are output in a table, which can be customized according to your own report.

4、Technical indicators and parameters:

project | Main parameters of the equipment |

product model | Bamtone/M60 |

optical system | Infinite far chromatic aberration correction optical system |

Optical magnification | 50x-500x (optional 1000x) |

industrial camera | Standard 6 megapixels, USB3.0, chip size 1/1.8 inch, maximum view 2.96*1.96 (5x) |

observing tube | As shown, the infinite hinge tee observation tube has a interpupillary distance adjustment of 50mm~76mm and a two-stage splitting ratio binoculars: three eyes =100:0 |

eyepiece | High eye point wide field of view eyepiece SWH10X-H/23mm, adjustable vision |

5X objective | Infinite distance semi-attenuating bright and dark field objective 45MM visible light metallographic objective 5X NA0.15 WD14.8mm |

10X objective | Infinite distance semi-attenuating bright and dark field objective 45mm visible light metallographic objective 10X NA0.30 WD8.5mm |

20Xobjective | Infinite distance semi-decay bright and dark field objective 45MM visible light metallographic objective 20X NA0.45 WD11.9mm |

50X objective | Infinite distance semi-attenuating bright and dark field objective 45MM visible light metallographic objective 50X NA0.75 WD3.0mm |

100X objective | Infinite distance semi-decay bright and dark field objective 45MM visible light metallographic objective 100X NA0.80 WD3.0mm (optional) |

revolving nosepiece | Objective lens turntable encoding system, with coded zoom objective lens turntable, real-time synchronous automatic switching software test ratio |

Light source on the rack | A retroreflective light fixture with a low-hand-position coarse coaxial focusing mechanism. Features a 35mm coarse adjustment stroke and 0.001mm fine-tuning precision. Includes anti-slip adjustment tension control and random upper limit protection. Integrated with a 100-240V wide-voltage system, it employs digital dimming technology with adjustable light intensity settings and reset functions. |

stage | 4 inch cargo platform, platform area 310*240mm, moving stroke: 100mmX100mm mechanical platform, X, Y direction coaxial adjustment |

collecting mirror | Swing-out achromatic condenser lens (N.A.0.9) |

epi-illuminator | Lighting device for bright and dark fields, with variable aperture, field of view aperture, adjustable center, with filter slots, with polarizer/compensator slots, |

lamphouse | 10W adjustable LED light chamber, transparent and reflective universal, predetermined center |

Camera interface | Photography camera accessories: 0.5X, C-type interface, adjustable focus, standard 0.5X interface |

Polarizing components | Biasing plate, 360-rotating biasing plate |

computer | Custom industrial computer, processor: I5 6500, Kingston 8G memory, Kingston 240G SSD, Dell mouse and keyboard, WIN10 64-bit system. |

display device | HD AOC 23.8 inch HDMI display |

Measurement software | Standard configuration: class microscope analysis software, photography, measurement, image splicing, automatic adjustment of encoding zoom, report output, etc |

scaleplate | High precision micrometer, grid value 0.01mm |

5、Configuration scheme:

number | substance | unit | quantity | remarks | |

1 | microscope | unit | 1 | Standard: Bamtone/M60, light and dark field transitive model | |

2 | objective | unit | 5 | Standard: infinity semi-reducing long-range bright and dark field objective, 5X,10X,20X,50X | |

3 | Polarization plate | Combos | 1 | Standard: tilt mirror insert, 360-rotating tilt mirror insert. | |

4 | Digital dimming system | Combos | 1 | Standard: digital dimming system, with light storage function. | |

5 | Microscope software | Combos | 1 | Standard: Bamtone microscope analysis software | |

6 | Calibration scale | Units

| 1 | Standard: high precision micrometer, grid value 0.01mm | |

7 | desktop computer | Combos | 1 | Standard: Custom industrial computer, processor: I5 6500, Kingston 8G memory, Kingston 240G SSD, Dell mouse and keyboard, WIN10 64-bit system. | |

8 | display device | Combos | 1 | Standard: HD AOC 23.8 inch HDMI display. | |

9 | industrial camera | Units | 1 | Standard: 6 megapixels, USB3.0, chip size 1/1.8 inch, maximum view 2.96*1.96 (5x) | |

10 | CTV camera interface | Units | 1 | Standard: 0.5 times CTV | |

11 | operating specification | Units | 1 | Standard: Simplified Chinese version | |

12 | certificate | Units | 1 | standard configuration | |

The following are optional accessories | |||||

1 | Automatic zoom system | Combos | 1 | The automatic zoom system can control the microscope objective to switch magnification in the software | |

2 | DIC differential interference plate | Units | 1 | Optional differential interference plate (electrical particle explosion and protrusion detection) | |

3 | CCD camera | Units | 1 | 6.3 megapixels, USB3.0, chip size 1/1.8 inch, maximum view 2.95*1.97 (5x) | |

4 | CCD camera | Units | 1 | 12 megapixels, USB2.0, chip size 1/2.3 inch, maximum view 2.38*1.88 (5x) | |

5 | CCD camera | Units | 1 | 20 megapixels, USB3.0, chip size 1/1.8 inch, maximum view 2.87*2.15 (5x) | |

6 | CCD camera | Units | 1 | 5.1 megapixel color chip camera, USB2.0, chip size 1/2.5 inch, maximum view 2.28*1.71 (5x) | |

7 | objective | Units | 1 | Infinite far semi-decay distance bright and dark field objective 100X. | |

6、List of breakable parts/consumables:

number | apellation | specifications | classification | instruction |

1 | industrial camera | 6 megapixels | quick-wear part | breakable |

2 | LED lamp bulb | 12V | expendable | Normal life aging |

3 | display screen | AOC 23.8 inch | quick-wear part | breakable |

4 | Calibration scale | G value 0.01mm | quick-wear part | Glass products, fragile |

Send Inquiry to This Supplier

You May Also Like

-

Desktop Hole Copper Surface Test T70US$ 8435MOQ: 1 Combo

-

Ion Contamination Tester Ict7563US$ 9880MOQ: 1 Combo

-

Ion Pollution Tester Bamtone/Ict3020US$ 9700MOQ: 1 Combo

-

Ion Contamination Tester Bamtone Ict4063US$ 9850MOQ: 1 Combo

-

Bamtone T90 Automatic Copper Thickness Inspection MachineUS$ 42055MOQ: 1 Combo

-

Automatic Current Withstand Tester Bamtone HCT80US$ 49000MOQ: 1 Combo

-

Bamtone MCT Series Multi-channel Copper Thickness Testing SystemNegotiableMOQ: 1 Combo

-

China Bamtone Technology TDR Impedance Analyzer High Bandwidth Impedance Test 20G BandwidthUS$ 42060MOQ: 1 Combo

-

China Bamtone Technology TDR Impedance Analyzer High Bandwidth Impedance Test 15G BandwidthUS$ 21030MOQ: 1 Combo

-

Bamtone/M60 Metallographic MicroscopeNegotiableMOQ: 1 Combo