Testing Machine Specification:

Capacity | Simply Supported Beams:7.5, 15, 25, 50J | Izod Beams:2.75J、5.5J |

| Impact velocity | 3.5m/s, 2.9m/s or specified | |

| Test angle | 150° | |

| Impact blade angle | 30°±l° | |

| Distance between jaw and support line | 60mm, 70 mm,95mm | |

| Blade filleted radius | R=2±0.5mm | R=0.8mm±0.2mm |

| Display | LCD Touch Screen | |

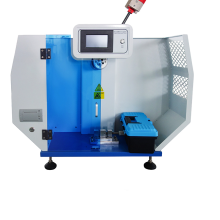

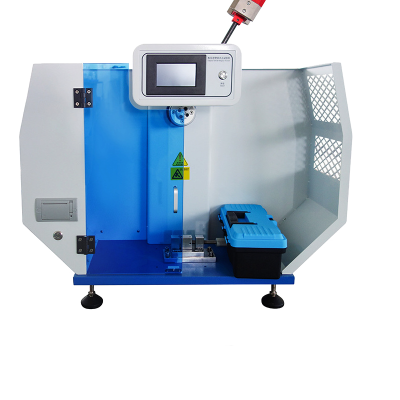

| Model | GC-XJL-5/5.5D | |

| Power | AC220V±10%, 50/60Hz | |

I. Impact Tester Overview

1. Test Principle

-Definition

Definition: Impact testing is used to determine the notched impact strength of materials (especially plastics and polymers) and to assess their impact resistance by the energy of fracture at the notch of a sample impacted by a pendulum.

Test criteria:

ASTM D256: Standard notched specimen size is 63.5 x 12.7 x 3.2 mm with a notch depth of 2.54 mm.

ISO 180: International standard with similar specimen size, but some parameters are slightly different.

2. Equipment Composition

Pendulum system: a pendulum with adjustable energy (usually in the range of 1-25 J) that impacts the sample after release.

Sample fixture: Holds the sample vertically to ensure that the notch is aligned with the impact edge.

Energy display unit: measures the difference in energy before and after the impact of the pendulum and calculates the impact strength in kJ/m² or ft-lb/in.

Safety shield: prevents splashing of debris and guarantees safe operation.

II. Applications in plastics testing

1. Applicable materials

Engineering plastics: ABS, PC (polycarbonate), nylon (PA), POM (polyacetal), etc.

Thermoplastics: PP, PE, PVC, etc.

Composite materials: glass fiber reinforced plastics, carbon fiber composites.

2. Testing purpose

Quality control: to verify that the impact resistance of plastic products meets industry standards (e.g. automotive, electronic housings).

Material R&D: Compare the effects of different formulations or processes on material toughness.

Failure analysis: Evaluate changes in material brittleness at low temperatures or after aging.

3. Test Steps

1.

Sample preparation:

Cut the specimen according to the standard size and machine a standard notch (V or U shape).

Adjust the temperature and humidity (e.g., 23°C/50% RH, or low-temperature ambient testing).

2. Calibrate the equipment:

Check the no-load energy loss of the pendulum (should be ≤1%).

Calibrate the energy scale to zero.

3. Test the operation:

Clamp the sample vertically with the notch back to the pendulum.

Release the pendulum to impact the sample and record the fracture energy.

4. Calculate the results:

Impact strength = Fracture energy (J) / Remaining thickness at notch (m)

III. Key factors affecting test results

Factor

Description

Notch machining accuracy

Notch shape (V-type/U-type) and depth (2-2.5mm) need to be in strict compliance with the standard, otherwise the data deviation is significant.

Temperature and humidity

Low temperatures (e.g. -30°C) increase material brittleness and require the use of environmental chambers to control test conditions.

Sample Orientation

Injection molded plastics may be anisotropic and the test direction (parallel/perpendicular flow direction) should be marked.

Pendulum Energy Selection

Too high an energy will result in complete breakage of the sample, too low an energy will not fracture, the appropriate range should be estimated based on the material.

Suggestions for equipment selection

1. Core parameters

Energy range: according to the material impact strength selection (such as general-purpose plastics selection 0-10 J, engineering plastics selection 10-25 J).

Pendulum pre-lift angle: usually 150 ° or greater, to ensure that the impact velocity is constant.

Data Acquisition: Digital display is preferred to pointer type, supports data export (e.g. USB or networking).

Send Inquiry to This Supplier

You May Also Like

-

High Temperature Differential Thermal AnalyzerUS$ 6000 - 8000MOQ: 1 Set

-

High Temperature Differential Thermal AnalyzerUS$ 6000 - 8000MOQ: 1 Set

-

Dsc Touch Screen Differential Scanning CalorimeterUS$ 6000 - 8000MOQ: 1 Set

-

Differential Scanning Calorimetry Analysis AnalyzerUS$ 6000 - 8000MOQ: 1 Set

-

High Sensitivity 0.001 Differential Scanning Calorimeter DSC With Cooling SystemUS$ 6000 - 8000MOQ: 1 Set

-

Differential Scanning Calorimeter (DSC) With Liquid Nitrogen CoolingUS$ 6000 - 8000MOQ: 1 Set

-

Differential Scanning Calorimeter (DSC) With Liquid Nitrogen CoolingUS$ 6000 - 8000MOQ: 1 Set

-

Type Differential Scanning Calorimeter for Polymer MaterialUS$ 6000 - 8000MOQ: 1 Set

-

Thermal Gravimetric Analyzer Dsc Differential Scanning CalorimeterUS$ 6000 - 8000MOQ: 1 Set

-

Diamond Dsc Differential Scanning CalorimeterUS$ 6000 - 8000MOQ: 1 Set