Baosteel B18R055 Oriented Silicon Steel High Magnetic Susceptibility and Low Iron Loss

I. Products

Baosteel orientated silicon steel B18R055 belongs to the magnetic domain refinement laser scribing series products, the thickness is 0.18mm, is currently the world's lowest iron loss of one of the orientated silicon steel, its typical iron loss value of P1.7/50 is only 0.54 W/kg, the magnetic performance index is significantly better than the same type of products in the international market, than the highest grade of two grades higher than the international market.

The product adopts Baosteel's self-developed low-temperature manufacturing process, and through precise control of grain orientation (the direction of grain arrangement is the same as the rolling direction), it achieves high magnetic permeability (J800 T up to 1.91) and low residual magnetic induction, which significantly reduces the energy loss in the alternating magnetic field.

II. Main uses

1. Transformer core: especially suitable for manufacturing super first-class energy-efficiency distribution transformers (such as S15-M-200/10, S15-M-400/10), its low iron loss characteristics can meet the requirements of no-load loss reduction of 20% -30%, to help ‘dual-carbon’ goal of power grid energy-saving transformation.

2. Motor cores: used in high-efficiency motors (e.g. new energy vehicle drive motors, industrial motors) to improve motor efficiency and reduce energy waste by optimising electromagnetic properties.

3. ultra-high voltage transmission equipment: such as ±1100kV ultra-high voltage DC converter transformers, replacing imported materials, breaking international monopolies, and supporting major national projects (e.g., the West-to-East Electricity Transmission and the Three Gorges Project).

It is estimated that if the national high energy-consuming transformers are upgraded with B18R055, the annual power saving can reach 90 billion degrees, close to the annual power generation of the Three Gorges Power Station.

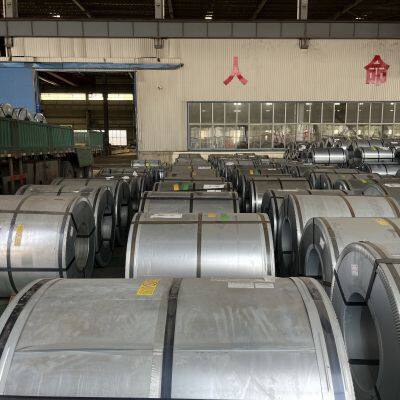

III. Storage and maintenance

1. Environmental control:

- The storage area needs to be kept sealed to ensure that the temperature difference between the steel coil temperature and the dew point of the storage area is ≥5°C to avoid moisture condensation leading to rust.

- If stored for more than half a year, the integrity of the packaging needs to be checked, and coils damaged in transport should be resealed and wrapped with rust-proof paper.

2. Rust treatment:

- Coils found to be rusty should be used on a priority basis to avoid further oxidation.

- If necessary, sealing treatment can be carried out and professional anti-rust coating is chosen to protect the edges.

3. Handling specification:

- Avoid collision or scratching the surface coating during lifting, which will affect the electromagnetic performance.

IV. Payment modalities

Only support T/T payment, the implementation of the FOB standard, the first to determine the variety and grade of silicon steel, sign the contract prepayment of 40%, in the delivery period the goods ready to send to the designated domestic port (such as Tianjin Port), after settlement of the final payment, the goods loaded on the ship.

summaries

With its excellent magnetic properties (low iron loss, high permeability) and advanced production process, Baosteel B18R055 has become a core material for efficient power equipment, and is widely used in transformers, motors and extra-high-voltage applications. Its storage needs to follow strict moisture-proof and sealing specifications to guarantee long-term stability. The promotion of this product not only enhances the international competitiveness of domestic high-end.

Send Inquiry to This Supplier

You May Also Like

-

Baosteel B20R070 Orientated Silicon Steel, Silicon Steel for Primary Energy-efficient TransformersUS$ 2870 - 2882MOQ: 1 Ton

-

Baosteel B20R075 Low Iron Loss High Magnetic Susceptibility Oriented Silicon SteelUS$ 2760 - 2773MOQ: 1 Ton

-

Baosteel B20R080 Oriented Silicon Steel 0.80W/kg Low Iron Loss and High Magnetic Induction Transformer Core MaterialUS$ 2515 - 2523MOQ: 1 Ton

-

Baosteel's World's First Capacity Oriented Silicon Steel B23R070US$ 3060 - 3070MOQ: 1 Ton

-

B23R075 Low Iron Loss High Magnetic Susceptibility Transformer Energy Saving Special SteelUS$ 2735 - 2742MOQ: 1 Ton

-

Baosteel B23R080 High Performance Transformer Silicon Steel, Iron Loss ≤ 0.8W/kgUS$ 2605 - 2617MOQ: 1 Ton

-

Baosteel B23R085 Low Iron Loss, High Magnetic Susceptibility Ultra-thin Oriented Silicon SteelUS$ 2525 - 2539MOQ: 1 Ton

-

Baosteel B23R090 0.23 Thickness Energy Consumption in Accordance With EU StandardsUS$ 2485 - 2492MOQ: 1 Ton

-

Baosteel B27R080 0.27mm Thick Energy-saving and Environmentally Friendly Transformer Materials of ChoiceUS$ 2795 - 2804MOQ: 1 Ton

-

Baosteel B27R085 UHV DC Transmission SteelUS$ 2635 - 2648MOQ: 1 Ton