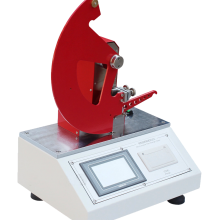

Tear Strength Tester for Textile/Film - ASTM D1424 & ISO 13937 Certified

The main technical parameters

Item | DR-B238-1 |

Test range | A: 50-8000mN B: 8000~16000mN |

Standard arm | (104±1)mm |

Beginning angle for tearing | 27.5°±0.5° |

Tear distance | (43±0.5)mm |

Tear distance | (2.8±0.3)mm |

This Tear Strength Tester is a state-of-the-art testing equipment specially designed for textile and film materials, aiming to accurately measure the tear strength of materials under different conditions.It strictly follows the international standards of ASTM D1424 and ISO13937, and combines modern technology with precision manufacturing techniques to provide the textile and film industry with accurate and reliable tear strength test data, helping users to evaluate material performance, optimize production processes and ensure product quality.

Core Advantages

(A) Standard certification, authoritative and reliable

- ASTM D1424 certification: ASTM D1424 is the American Society for Testing and Materials (ASTM) developed on the textile tear strength test standard method. Our testers are designed and calibrated in strict accordance with this standard to ensure that the testing process and results meet the requirements of ASTM D1424. This certification allows our testers to be widely recognized worldwide, providing users with an authoritative basis for testing.

- ISO13937 Certification: ISO13937 is a standard issued by the International Organization for Standardization (ISO) for the testing of the tearing properties of textiles and films. By obtaining ISO13937 certification, our testers further prove their reliability and compatibility in the international market. Whether in the domestic or international market, testing with our tester ensures that your products comply with international standards, providing a strong guarantee that your products will enter the international market.

(ii) High-precision Measuring System

- Advanced sensor technology: Equipped with high-precision force sensors and displacement sensors, these sensors utilize the latest sensing technology and materials with extremely high sensitivity and resolution. They can real-time and accurately monitor the force and displacement changes during the tearing process to ensure the accuracy and reliability of the measurement data. The sensors respond quickly and provide accurate measurements even under small changes in tearing force, providing a solid foundation for subsequent data analysis.

- Precise mechanical structure: The tester adopts a precise mechanical structure design to ensure stability and accuracy during the testing process. From the design of the fixture to the optimization of the transmission system, every detail is carefully polished to reduce the interference of external factors on the test results. For example, the fixture adopts special materials and surface treatment process, which can firmly clamp the sample to avoid sliding or deformation during the test process, thus ensuring the accuracy of the tear force measurement.

(iii) Diversified testing modes

- Multiple tear simulation: The tester supports multiple tear simulation, including single tongue tear, trouser tear, trapezoidal tear, etc., which can meet the testing needs of different types of textiles and film materials. Users can choose the appropriate tearing method according to the specific material characteristics and testing requirements, so as to reflect the tearing performance of the material more realistically.

- Flexible Test Parameter Setting: In order to adapt to different materials and test conditions, the instrument provides flexible test parameter setting function. Users can adjust the tearing speed, fixture spacing, sample size and other parameters to meet individual testing needs. This flexibility allows the tester to perform well in different application scenarios, providing users with more testing options.

(D) Humanized design concept

- Intuitive operation interface: The tester is equipped with a simple and intuitive operation interface, and all operation buttons and function menus are well laid out and easy to understand and operate. Even inexperienced users can familiarize themselves with the operation of the instrument in a short time and complete the test tasks easily. Detailed operation tips and help documents are also provided on the operation interface, which are convenient for users to refer to at any time to ensure the accuracy and standardization of operation.

- Automated testing process: In order to improve testing efficiency and reduce human error, the instrument adopts an automated testing process. Users only need to place the sample on the fixture, set the test parameters, the instrument will automatically complete the tearing process, and real-time recording and displaying test data. The entire testing process does not require human intervention, which greatly improves the accuracy and repeatability of the test.

Send Inquiry to This Supplier

You May Also Like

-

Multi-Material Tear Tester (Plastic/Rubber/Paper)US$ 2000 - 3000MOQ: 1 Set

-

Fabric Tear Resistance Meter Electronic Textile Paper Elmendorf Tearing Strength TesterUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Tearing Strength Tester ISO 1974 ASTM D1922 D1424 for Testing Fabric Tear ResistanceUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Tear Film Strength Digital Resistance Paper Tearing Machine Test Tester Equipment TestingUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Tearing Force Tester for Film Package Tear Tester Paper Tear Strength Testing MachineUS$ 2000 - 3000MOQ: 1 Set

-

Professional Paper Elmendorf Tearing Resistance Strength Tester Tear Strength Test Equipment Machine Burst TesterUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Paper Tearing Bursting Strength Test EquipmentUS$ 2000 - 3000MOQ: 1 Set

-

Temperature and Humidity Adhesive Tape Retentivity TesterUS$ 8750 - 12500MOQ: 1 Set

-

Laboratory Packaging Drop Double Wing Drop Test MachineUS$ 3000 - 5500MOQ: 1 Set

-

Computer Servo Control Carton Compression Testing MachineUS$ 2900 - 5500MOQ: 1 Set