The main technical parameters

Item | DR-B238-1 |

Test range | A: 50-8000mN B: 8000~16000mN |

Standard arm | (104±1)mm |

Beginning angle for tearing | 27.5°±0.5° |

Tear distance | (43±0.5)mm |

Tear distance | (2.8±0.3)mm |

I. Equipment Overview

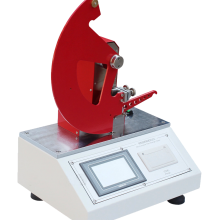

The Elmendorf Paper Tear Bursting Strength Test Equipment is a specialized instrument for evaluating the ability of paper to resist tearing and withstand internal pressure. It combines the Elmendorf tearing test principle and bursting strength test method to comprehensively analyze the performance of paper under the action of tearing force and internal pressure, providing important data support for paper quality control, production optimization and application selection.

Testing Principle

Tear Strength Test Principle (Elmendorf Method)

Based on the Elmendorf principle, a paper specimen with a defined cut is fixed on a fixture. By releasing the pendulum from a certain height, the cutting edge of the pendulum tears the paper along the cut. The energy consumed by the pendulum during the tearing process is related to the paper's ability to resist tearing, and the tearing strength of the paper is calculated using a specific formula based on the difference in height between the start and end positions of the pendulum, the mass of the pendulum, the moment of inertia, and other parameters. This method simulates the situation of paper being subjected to tearing force in actual use, and can more accurately reflect the tear resistance of paper.

Principle of Bursting Strength Test

The paper specimen sealed in a special container, and then gradually increase the pressure to the container, so that the paper to withstand the internal pressure. As the pressure increases, the paper ruptures when it reaches its endurance limit. The bursting strength of the paper is calculated by measuring the value of the pressure at which the paper ruptures, as well as the relevant dimensions of the paper and other parameters. Bursting strength reflects the resistance of the paper to withstand internal pressure, for some of the need for internal inflation or pressure environment of paper applications (such as balloon paper, packaging bags, etc.) is of great significance.

Third, the structure and characteristics of the equipment

Structure

Tear test part

Pendulum system: The pendulum is one of the core components, and its quality, shape and cutting edge design are precisely calculated and optimized. The shape and angle of the cutting edge must meet the requirements of the relevant standards to ensure that the tearing of paper can accurately simulate the actual use of the tearing situation. Different sizes of pendulums can be used to test paper with different tear strength ranges to extend the range of applications.

Fixture system: The fixture is used to firmly fix the paper specimen and prevent the specimen from moving or deforming during the test. The design of the fixture should be adapted to the size and shape of the paper, and there are corresponding fixtures for different types (such as flat paper, web cut specimens) and thicknesses of paper to ensure that the specimen is subjected to uniform force during the tearing process.

Measurement and display system: A high precision sensor is used to measure the energy change of the pendulum, the sensor converts the mechanical signal into electrical signal, which is then processed by the internal circuitry and microprocessor of the instrument, and finally the tear strength data is shown in digital form on the display screen. Some advanced equipments also have data storage and printing functions, which are convenient for users to record and analyze the test results.

Burst strength test section

Pressure generating system: It consists of gas source (e.g. air compressor or gas cylinder), pressure regulating device and pressure transmission pipeline, etc. The gas source provides the pressure source, the pressure regulating device and the pressure transmission pipeline. The gas source provides the pressure source, the pressure regulating device is used to accurately control the size of the pressure and the rate of increase, and the pressure transmission pipeline transmits the pressure uniformly to the test container to ensure that the paper specimen is tested under a stable pressure environment.

Test Vessel: Used to hold the paper specimen and withstand the internal pressure. The design and manufacture of the test vessel needs to ensure its sealing and pressure resistance, while also taking into account the installation and fixation of the specimen to ensure that the pressure is uniformly applied to the specimen. Vessel materials usually have good pressure resistance and chemical stability to prevent interference with test results.

Measurement and control system: A high-precision pressure sensor is used to measure the pressure change in the vessel. The sensor converts the pressure signal into an electrical signal, which is then processed and displayed by the control system. The control system can also set the upper limit of pressure, the speed of pressure increase and other parameters, and automatically record the relevant data when the specimen ruptures to ensure the accuracy and repeatability of the testing process.

Features

High-precision Measurement: Designed and manufactured in strict accordance with international standards (such as ISO 1974, ASTM D1922, etc.), the test results of both tear strength and burst strength are highly accurate and repeatable, providing reliable data support for paper quality control and product development.

Multi-functional integration: integrating the two testing functions of tear strength and burst strength, a single device can meet the performance testing needs of paper in different application scenarios, saving laboratory space and equipment procurement costs.

Simple operation: The operation process of the equipment is relatively simple and can be mastered by operators after a short period of training. For example, the installation of specimens, parameter settings and other operations are clearly indicated and labeled, reducing the possibility of operational errors.

Wide range of application: It can be used for tearing and bursting strength testing of various types of paper, including writing paper, printing paper, packaging paper, specialty paper, etc., meeting the needs of different industries and application scenarios.

Testing process

Sample Preparation

Tear strength test samples: Randomly cut out specimens of specified sizes from the paper to be tested, generally need more than one specimen to ensure the representativeness of the test results. The size of the specimen should meet the requirements of the relevant standards, and in the specimen in accordance with the prescribed method of making incisions, the shape, size and location of the incision have strict requirements.

Bursting Strength Test Specimen: Similarly, cut the specimen of suitable size from the paper to be tested and seal it in the test container to ensure good sealing and prevent air leakage in the testing process.

Installation of specimen

Tear Strength Test: Mount the prepared specimen on the fixture correctly, making sure that the specimen is firmly fixed and the direction of the cut is consistent with the direction of the cutting edge of the pendulum. For some special papers, it may be necessary to pay attention to the placement direction of the specimen to ensure the accuracy of the test results.

Bursting Strength Test: Connect the test vessel with sealed specimen to the pressure transmission pipeline correctly, check whether the connection part is well sealed, and make sure the pressure can be evenly transmitted to the specimen.

Setting parameters

Send Inquiry to This Supplier

You May Also Like

-

Drop Testing Machine for Food Product Packaging Drop ResilienceUS$ 2000 - 4000MOQ: 1 Set

-

Drop Testing Machine for Shock - Pre - Conditioned Drop TestUS$ 2000 - 4000MOQ: 1 Set

-

Drop Testing Machine for Industry Standard Compliance Drop InspectionUS$ 2000 - 4000MOQ: 1 Set

-

Paper Box Compression Performance Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Toy Packaging Cardboard Box Compression Performance Analysis Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Large Cardboard Box Compression Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Compression Testing Machine for Stacking Multi-layer Cardboard BoxesUS$ 2900 - 5500MOQ: 1 Set

-

Automatic Temperature and Humidity Control Holding Force Testing MachineUS$ 8750 - 12500MOQ: 1 Set

-

Coating Adhesion Constant Temperature and Humidity Retention Testing EquipmentUS$ 8750 - 12500MOQ: 1 Set

-

Automatic Temperature and Humidity Control Holding Force Testing MachineUS$ 8750 - 12500MOQ: 1 Set