Bulk Discount! Tear Strength Testers for Global Packaging Suppliers

The main technical parameters

Item | DR-B238-1 |

Test range | A: 50-8000mN B: 8000~16000mN |

Standard arm | (104±1)mm |

Beginning angle for tearing | 27.5°±0.5° |

Tear distance | (43±0.5)mm |

Tear distance | (2.8±0.3)mm |

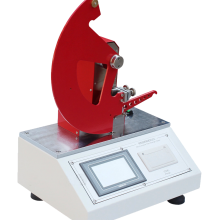

Tear Strength Testers for Global Packaging Suppliers: Specialized Testing Equipment to Safeguard Packaging Material Quality

In the global packaging industry, the performance of packaging materials is crucial to protecting products, ensuring transportation safety and enhancing user experience. Among them, tear strength, as one of the key indicators of the quality of packaging materials, is directly related to the reliability and durability of packaging during use. As a leading global packaging supplier, we are proud to introduce this high-performance tear strength tester to provide accurate and reliable tear strength testing solutions for the packaging industry.

I. Product Overview

This Tear Strength Tester is an advanced testing equipment specially designed for packaging materials, aiming to accurately measure the tear strength of various packaging materials under different conditions. It combines international advanced testing technology and precise manufacturing process, and strictly follows the relevant global standards and specifications to ensure the accuracy and reliability of the test results. Whether it is paper, plastic film, composite materials or other packaging materials, the tester provides a comprehensive and accurate tear strength assessment, offering strong quality assurance for packaging suppliers and manufacturers.

II. Core Advantages

(i) Wide applicability

- Compatible with a wide range of materials: the tester has excellent versatility and can be adapted to the testing of various types of packaging materials. Whether it is common paper, corrugated cardboard, plastic films (such as polyethylene, polypropylene, polyvinyl chloride, etc.) or complex composite materials, the tester is able to conduct accurate tear strength tests. This makes it an indispensable and versatile test equipment in the packaging industry, meeting the needs of different customers and different materials testing.

- Different Packaging Forms Support: Considering the diversity of packaging forms, the tester is designed with a flexible fixture system that can accommodate packaging samples of different shapes and sizes. Whether it is sheet material, roll material or molded packaging products, it can be easily tested to ensure that accurate tear strength data can be obtained in a variety of practical application scenarios.

(ii) High-precision measurement system

- Advanced sensor technology: Equipped with high-precision force sensors and displacement sensors, these sensors utilize leading international sensing technology with extremely high sensitivity and resolution. The force sensor can accurately capture small force changes during the tearing process with a measurement accuracy of ±0.05%FS (full scale), ensuring accurate measurement of the tearing force. The displacement sensor tracks the displacement of the specimen in real time, providing detailed data support for analyzing the tearing characteristics of the material, with a displacement measurement accuracy of ±0.01mm.

- Precise control system: Adopting advanced digital control system, it can precisely control and adjust the testing process. Through the preset test parameters, such as tearing speed, loading mode, etc., the system can automatically control the operation of the test equipment to ensure the consistency and stability of the test conditions. At the same time, the control system also has real-time data acquisition and analysis functions, which can timely detect and correct abnormalities in the testing process to ensure the accuracy and repeatability of the test results.

(C) High-speed and efficient testing

- Fast test speed: In order to meet the needs of mass production and quality inspection, the tester has high-speed testing capabilities. Its test speed can be adjusted in a wide range according to customer needs, up to [X] mm / s (here you can set the specific speed according to the actual product). High-speed testing not only greatly reduces the testing time of individual samples and improves testing efficiency, but also better simulates the high-speed stretching situation in the actual production process, making the test results closer to the actual application scenarios.

- Automated testing process: In order to further improve testing efficiency and reduce human error, the tester adopts an automated testing process. Users only need to place the sample on the fixture, set the test parameters, the instrument will automatically complete the tearing process, and real-time recording and displaying test data. The whole testing process without human intervention, easy and fast operation, greatly improving the accuracy and repeatability of the test.

(Intelligent data analysis and management

- Powerful data analysis function: the instrument has built-in professional data analysis software, which can process and analyze the test data in real time. Users can intuitively view the tear force curve, tear strength value and other key data through the software interface, and carry out data statistics and analysis. The software also supports data storage and export function, which is convenient for users to further analyze and study the test results, such as drawing trend graphs, comparing the performance differences between different batches of products, etc.

- Data management and traceability: In order to meet the needs of quality management and traceability, the tester is equipped with perfect data management functions. All test data are automatically recorded and stored in the internal database of the instrument, and users can quickly query and retrieve the historical test data according to the sample number, test date, tester and other information. At the same time, the software also supports data backup and recovery functions to ensure data security and integrity.

Application Fields

- Packaging material manufacturers: for quality control of raw materials and product quality testing, to ensure that the production of packaging materials in line with quality standards and performance requirements. By accurately measuring the tear strength, the enterprise can optimize the production process, improve product quality and market competitiveness.

- Manufacturers of packaging products: Tear strength tests are conducted on raw materials and finished packaging products to assess the performance of packaging under different usage environments. This helps manufacturers to select suitable packaging materials, design reasonable packaging structures, and improve product protection and user experience.

- Third-party testing organizations: Provide professional quality testing services for the packaging industry, conducting tear strength tests for various packaging materials according to international standards and customer requirements. Testing organizations can rely on the accuracy and reliability of the tester to provide customers with fair and authoritative test reports, to protect the fair trade in the market and the rights and interests of consumers.

Strict quality control and perfect after-sales service

(A) Comprehensive quality inspection system

We have established a comprehensive quality inspection system, from raw material procurement, production and processing to product assembly and factory inspection, each link is under strict control. During the production process, we adopt advanced production equipment and testing methods to carry out strict quality testing of each component to ensure that it meets the relevant standards and requirements. After the product is assembled, we will also carry out comprehensive performance test and stability test, only through all the tests of the product can be sold, so as to ensure that each tear strength tester has excellent quality and reliability.

Send Inquiry to This Supplier

You May Also Like

-

Elmendorf Tear Film Strength Digital Resistance Paper Tearing Machine Test Tester Equipment TestingUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Tearing Force Tester for Film Package Tear Tester Paper Tear Strength Testing MachineUS$ 2000 - 3000MOQ: 1 Set

-

Professional Paper Elmendorf Tearing Resistance Strength Tester Tear Strength Test Equipment Machine Burst TesterUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Paper Tearing Bursting Strength Test EquipmentUS$ 2000 - 3000MOQ: 1 Set

-

Temperature and Humidity Adhesive Tape Retentivity TesterUS$ 8750 - 12500MOQ: 1 Set

-

Laboratory Packaging Drop Double Wing Drop Test MachineUS$ 3000 - 5500MOQ: 1 Set

-

Computer Servo Control Carton Compression Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Paper Package Clamp Compression Machine Cardboard Clamp Force Testing EquipmentUS$ 6000 - 12000MOQ: 1 Set

-

Drop Testing Machine With Adjustable Drop Height MechanismUS$ 2000 - 4000MOQ: 1 Set

-

Drop Testing Machine for Food Product Packaging Drop ResilienceUS$ 2000 - 4000MOQ: 1 Set