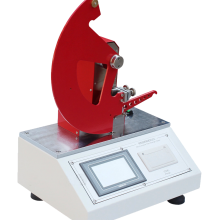

Elmendorf Tear Film Strength Digital Resistance Paper Tearing Machine Test Tester Equipment Testing

The main technical parameters

Item | DR-B238-1 |

Test range | A: 50-8000mN B: 8000~16000mN |

Standard arm | (104±1)mm |

Beginning angle for tearing | 27.5°±0.5° |

Tear distance | (43±0.5)mm |

Tear distance | (2.8±0.3)mm |

About the Elmendorf Tear Film Strength Digital Resistance Paper Tear Machine Tester (Test Equipment)

I. Equipment Overview

1. Versatile use

- This test equipment is mainly used to test the tear strength of film, paper and other materials. It is based on the Elmendorf principle, whereby a specific mechanical device applies a tearing force to the sample and measures the associated energy or force value to derive a tear strength index.

2. Digital Display Features

- Adopting digital display technology provides higher accuracy and intuitive reading compared to the traditional dial reading method. The operator can read the test data more accurately, and the equipment can usually display the value of tear strength directly, reducing the workload of manual calculation.

Second, the test principle related to

1. Film and paper tear test principle

- For film and paper, the equipment also uses a specimen with a cut-out. The pendulum is released from a certain height and its cutting edge tears the sample along the incision. During the tearing process, the device measures the energy consumption of the pendulum or directly measures the change in force during the tearing process. The tearing strength is calculated according to a predetermined formula, taking into account the relevant parameters of the pendulum (e.g. mass, moment of inertia, etc.) as well as the dimensions of the sample.

- When testing films, due to their thin thickness and flexibility, the equipment may require special designs or adjustments to fixtures, pendulums, etc. to ensure that the tearing force can be accurately applied and the results measured. For paper, we should consider the fiber direction of the paper, grams and other factors on the tear strength, the test parameters of the equipment settings and operation also need to be adapted accordingly.

Three, the structure of the equipment components

1. Pendulum assembly

- Pendulum is the key component to generate the tearing force, and its quality and shape are precisely designed. For film and paper testing, the cutting edge of the pendulum may be finer and smoother to minimize additional damage to the sample and to ensure that the tearing process meets standard requirements. Components such as the rotating shaft of the pendulum also have a high degree of precision to ensure stability and repeatability of the pendulum movement.

2. Clamping system

- Fixtures are designed differently for the different characteristics of film and paper. For film, the fixture needs to be able to firmly clamp the film without causing excessive deformation or damage to the film, usually with a certain degree of elasticity of the fixture or a special clamping method. For paper, the fixture should ensure that the paper will not slip out of the fixture during the tearing process, and be able to evenly transmit the tearing force.

3. Digital measurement and control system

- Sensors are included to detect the movement and energy changes of the pendulum. The sensor transmits the collected data to the control system, which processes and converts this data into a tear strength value shown on a digital display. At the same time, the control system can also set the test parameters, such as specimen size, test mode (film or paper mode, etc.), data recording mode, etc.

Four, the test process

1. Sample preparation

- For film and paper, the sample sampling method has certain requirements. Generally, a specimen of a specified size is cut randomly from the material and a standardized cut is made in the specimen. For example, specimen sizes for paper may have specific length and width requirements based on different standards, and the length of the cutout is specified accordingly.

2. Mounting the sample

- Mount the prepared sample correctly on the fixture, making sure that the sample is positioned accurately and that the direction of the notch is consistent with the direction of movement of the pendulum cutting edge. For thin-film samples, be careful to avoid defects such as wrinkles or bubbles during the mounting process, so as not to affect the test results.

3. Equipment setup and testing

- According to the sample type (film or paper) in the digital control system of the equipment to set the appropriate parameters, such as selecting the appropriate test mode, range, etc.. Then release the pendulum for tearing test, the equipment automatically records and calculates the tear strength data.

4. Data processing and analysis

- The equipment directly displays the tear strength value, and the operator can calculate the average value and analyze the data statistically according to the results of multiple tests to evaluate whether the tearing performance of the film or paper meets the requirements.

Send Inquiry to This Supplier

You May Also Like

-

Computer Servo Control Carton Compression Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Paper Package Clamp Compression Machine Cardboard Clamp Force Testing EquipmentUS$ 6000 - 12000MOQ: 1 Set

-

Drop Testing Machine With Adjustable Drop Height MechanismUS$ 2000 - 4000MOQ: 1 Set

-

Drop Testing Machine for Food Product Packaging Drop ResilienceUS$ 2000 - 4000MOQ: 1 Set

-

Drop Testing Machine for Shock - Pre - Conditioned Drop TestUS$ 2000 - 4000MOQ: 1 Set

-

Drop Testing Machine for Industry Standard Compliance Drop InspectionUS$ 2000 - 4000MOQ: 1 Set

-

Paper Box Compression Performance Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Toy Packaging Cardboard Box Compression Performance Analysis Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Large Cardboard Box Compression Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Compression Testing Machine for Stacking Multi-layer Cardboard BoxesUS$ 2900 - 5500MOQ: 1 Set