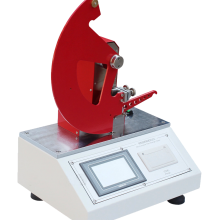

Elmendorf Tearing Force Tester for Film Package Tear Tester Paper Tear Strength Testing Machine

The main technical parameters

Item | DR-B238-1 |

Test range | A: 50-8000mN B: 8000~16000mN |

Standard arm | (104±1)mm |

Beginning angle for tearing | 27.5°±0.5° |

Tear distance | (43±0.5)mm |

Tear distance | (2.8±0.3)mm |

I. Instrument Overview

Elmendorf principle basis

Both the Elmendorf Tear Force Tester and the Paper Tear Strength Tester work on the Elmendorf principle. This principle measures the tearing properties of a material by utilizing the potential energy of a pendulum to be converted into the energy required to tear the specimen.

When the pendulum is released from a certain height, its cutting edge tears the material along a pre-made incision in the specimen, and the energy loss of the pendulum corresponds to the energy required to tear the material, allowing the tear strength of the material to be calculated.

Applicable material range

Mainly applicable to film and paper materials. For film packaging materials, such as food packaging film, plastic film, etc., it is possible to accurately measure the tearing conditions that may be encountered during packaging use. For paper, whether it is printing paper, packaging paper or specialty paper, can test its tear strength, which is very important for the quality control and performance evaluation of paper.

Second, the structure and characteristics of the instrument

Structure

Pendulum system: The pendulum is one of the core components of the instrument, with precise quality and shape design. The material and angle of the cutting edge have been specially treated to ensure that the tearing of the specimen can accurately simulate the tearing situation in actual use, and that the sharpness of the cutting edge can remain relatively stable under different test times.

Fixture system: Suitable fixtures are designed for film and paper. For film, the fixtures need to be able to fit tightly on the film surface to prevent the film from sliding during the test without causing additional damage to the film, such as indentation. For paper, the fixture should be able to hold the paper firmly and ensure that the force on the paper is uniform in the tearing direction.

Measuring system: A high-precision sensor is used to measure the energy change of the pendulum. The sensor converts the conversion of mechanical energy into electrical signals, which are then processed by the instrument's internal circuitry and microprocessor, and finally the tear strength data is shown digitally on the instrument's display.

Features

Highly accurate measurement: The tear strength of film and paper can be precisely measured with high accuracy and repeatability. This is very important for quality control and product development, and can help companies to ensure that their products comply with relevant standards and specifications.

Easy to operate: The instrument's operator interface is designed to be simple and intuitive, allowing the operator to quickly master the instrument's operation. Usually, it is only necessary to install the specimen on the fixture correctly, set the relevant parameters (such as test mode, unit, etc.), and then start the test program.

Multiple test modes: Different test modes can be selected according to different material properties and test requirements. For example, for different thicknesses and materials of film or paper, you can choose the appropriate energy range and test speed and other parameters to get the best test results.

Preparation of test samples

Film samples

Sampling: Randomly cut out a certain size specimen from the film roll or finished package. Generally speaking, the size of the specimen needs to meet the requirements of the relevant standards (such as ISO or ASTM standards) to ensure that the test results are comparable.

Notching: Notches are made in the specimen according to the specified method and size. The shape and size of the cutout has a significant impact on the test results. Standard cutout shapes, such as rectangular or circular portions, are usually used, and the depth of the cutout is also strictly defined.

Paper Samples

Sampling: Random samples are taken from rolls or stacks of paper. Sample sizes may vary for different types and uses of paper, but all follow the appropriate standard specifications.

Notching: Similar to film samples, precise notches are made in the paper specimen. Due to the characteristics of the fiber structure of paper, the production of incisions need to be more careful to avoid unnecessary damage to the paper fiber, affecting the test results.

Test Procedure

Installation of specimen

Mount the prepared film or paper specimen correctly on the fixture. For film, make sure that the film fits flat on the fixture surface without folds or bubbles; for paper, align the edges of the paper with the edges of the fixture and make sure that the paper is in the correct position in the tearing direction.

Setting parameters

Depending on the type of material (film or paper), the expected tear strength range, and the requirements of the relevant standard, set the appropriate test parameters on the instrument. These parameters may include the start angle of the pendulum (which affects the amount of energy released), the speed of the test (important for some speed-sensitive materials), the energy range, etc.

Conducting the test

The instrument's test program is initiated and the pendulum begins to release and tear the specimen along the incision. During the tearing process, the instrument automatically measures the energy loss of the pendulum and converts it into a tear strength value.

Data Recording and Analysis

The instrument directly displays the tear strength value obtained from the test. In order to obtain more reliable results, it is often necessary to test several specimens (usually not less than 5) and then calculate the average value, standard deviation and other statistical parameters of these data. By analyzing these data, it is possible to assess whether the tearing properties of the film or paper meet the quality requirements and to compare them with different batches or products from different suppliers.

V. Application Areas

Packaging industry

In the packaging industry of food, pharmaceuticals, daily necessities, etc., the Film Packaging Tear Force Tester and Paper Tear Strength Tester are used to test the tearing performance of packaging materials. For example, the aluminum foil composite film in food packaging needs to have a certain tear strength to prevent accidental breakage during transportation and storage; the wrapping paper of high-grade gift boxes needs to have a suitable tear strength, which not only ensures the aesthetics of the package, but also facilitates the operation of consumers when it is opened.

Paper Industry

Paper companies use these testing machines to control the quality of paper. By testing the tear strength of the paper, the papermaking process parameters can be adjusted, such as fiber ratios, degree of pulping, etc., in order to improve the overall quality of the paper. For specialty papers (e.g., art paper, anti-counterfeiting paper, etc.), tear strength is one of its important performance indicators, which directly affects the use value and market price of the paper.

Material R&D

In the development of new film and paper materials, these testers are an important tool for evaluating material performance. By testing the tear strength of materials under different formulations and production processes, R&D personnel can optimize the performance of the materials and develop new materials with better tear properties to meet the specific needs of different fields.

Send Inquiry to This Supplier

You May Also Like

-

Paper Package Clamp Compression Machine Cardboard Clamp Force Testing EquipmentUS$ 6000 - 12000MOQ: 1 Set

-

Drop Testing Machine With Adjustable Drop Height MechanismUS$ 2000 - 4000MOQ: 1 Set

-

Drop Testing Machine for Food Product Packaging Drop ResilienceUS$ 2000 - 4000MOQ: 1 Set

-

Drop Testing Machine for Shock - Pre - Conditioned Drop TestUS$ 2000 - 4000MOQ: 1 Set

-

Drop Testing Machine for Industry Standard Compliance Drop InspectionUS$ 2000 - 4000MOQ: 1 Set

-

Paper Box Compression Performance Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Toy Packaging Cardboard Box Compression Performance Analysis Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Large Cardboard Box Compression Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Compression Testing Machine for Stacking Multi-layer Cardboard BoxesUS$ 2900 - 5500MOQ: 1 Set

-

Automatic Temperature and Humidity Control Holding Force Testing MachineUS$ 8750 - 12500MOQ: 1 Set