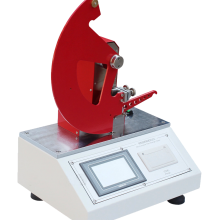

Digital Tear Tester for Plastic Packaging - 0-100N Range ±0.1% Accuracy

The main technical parameters

Item | DR-B238-1 |

Test range | A: 50-8000mN B: 8000~16000mN |

Standard arm | (104±1)mm |

Beginning angle for tearing | 27.5°±0.5° |

Tear distance | (43±0.5)mm |

Tear distance | (2.8±0.3)mm |

In the plastic packaging industry, the tearing properties of packaging materials are one of the most important indicators for assessing their quality and usability. To ensure that plastic packaging can effectively protect products during transportation, storage and use, it is vital to accurately measure its tear strength. We are proud to introduce this digital tear tester for plastic packaging, which provides an accurate and reliable tear performance testing solution for the plastic packaging industry with advanced technology and excellent performance.

I. Product Overview

This digital tear tester is an advanced testing equipment specially designed for plastic packaging materials, aiming to accurately measure the tear strength of plastic packaging under different conditions. It combines modern digital technology with precision mechanical design to quickly and accurately obtain tearing performance data, providing strong support for plastic packaging research and development, production and quality control. By simulating the tearing situation in the actual use scenario, the tester helps users to deeply understand the mechanical properties of plastic packaging materials, optimize the packaging design and production process, and improve the market competitiveness of products.

Core Advantages

(A) High-precision measurement system

- Advanced sensor technology: Equipped with high-precision force sensors and displacement sensors, these sensors adopt international leading sensing technology with extremely high sensitivity and resolution. They can real-time and accurately monitor the force and displacement changes during the tearing process, ensuring the accuracy and reliability of the measurement data. Even under small changes in tearing force, the sensors can respond quickly and provide accurate measurement results, providing a solid foundation for subsequent data analysis.

- Precise control system: Adopting advanced digital control system, it is able to control and regulate the testing process precisely. Through the preset test parameters, such as tearing speed, loading mode, etc., the system can automatically control the operation of the test equipment to ensure the consistency and stability of the test conditions. At the same time, the control system also has real-time data acquisition and analysis functions, which can detect and correct abnormalities in the testing process in a timely manner to ensure the accuracy and repeatability of the test results.

(ii) Diversified testing modes

- Multiple tear simulation: the tester supports multiple tear simulation, including single tongue tear, trouser tear, trapezoidal tear, etc., to meet the testing needs of different types of plastic packaging materials. Users can choose the appropriate tearing method according to the specific material properties and testing requirements, so as to reflect the tearing performance of the material more realistically.

- Flexible sample size adaptation: In order to adapt to different sizes and shapes of plastic packaging samples, the tester is equipped with an adjustable fixture system. Users can flexibly adjust the distance and position of the fixture according to the actual size of the samples to ensure that the samples can be firmly clamped during the testing process, avoiding the sliding or deformation of the samples that may affect the test results.

(Digital operation and data analysis

- Intuitive operation interface: The tester is equipped with a simple and intuitive digital operation interface, all the operation buttons and function menus are well laid out and easy to understand and operate. Even inexperienced users can familiarize themselves with the operation of the instrument in a short period of time and easily complete the testing tasks. Detailed operation tips and help documents are provided on the operation interface, which are convenient for users to refer to at any time to ensure the accuracy and standardization of operation.

- Powerful data analysis function: the instrument has built-in professional data analysis software, which can process and analyze the test data in real time. Users can intuitively view the tear force curve, tear strength value and other key data through the software interface, and carry out data statistics and analysis. In addition, the software also supports data storage and export functions, which is convenient for users to further analyze and study the test results.

(D) Humanized design concept

- Convenient operation process: In order to improve testing efficiency and reduce human error, the tester adopts an automated testing process. Users only need to place the sample on the fixture, set the test parameters, press the start button, the instrument will automatically complete the tearing process, and real-time recording and displaying test data. The whole testing process requires no manual intervention, which greatly improves the accuracy and repeatability of the test.

- Easy to maintain and repair: The design of the tester has fully considered the maintenance and repair needs of users. The instrument adopts modularized design, each component is easy to disassemble and replace, which is convenient for users to carry out routine maintenance and troubleshooting. At the same time, the instrument's shell is made of high-quality materials with good protection performance, which can effectively prevent dust, moisture and other external factors from affecting the instrument and prolong the service life of the instrument.

Third, the field of application

- Plastic packaging manufacturers: used for quality control of raw materials and product quality testing, to ensure that the production of plastic packaging in line with quality standards and performance requirements. Through accurate measurement of tear strength, enterprises can optimize the production process, improve product quality and market competitiveness.

- Food, pharmaceutical and other industries: The tearing performance of packaging materials is evaluated to ensure that the packaging can effectively protect the product during transportation, storage and use. For example, in the food industry, good tearing performance can prevent the packaging from rupturing during the opening process, ensuring the hygiene and safety of food.

- Scientific research institutions and universities: to carry out research and development work on plastic packaging materials and provide experimental basis for the design and performance optimization of new materials. Researchers can use the tester to study the tearing mechanism of materials in depth and explore new material formulations and processing techniques.

Send Inquiry to This Supplier

You May Also Like

-

Fabric Tear Resistance Meter Electronic Textile Paper Elmendorf Tearing Strength TesterUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Tearing Strength Tester ISO 1974 ASTM D1922 D1424 for Testing Fabric Tear ResistanceUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Tear Film Strength Digital Resistance Paper Tearing Machine Test Tester Equipment TestingUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Tearing Force Tester for Film Package Tear Tester Paper Tear Strength Testing MachineUS$ 2000 - 3000MOQ: 1 Set

-

Professional Paper Elmendorf Tearing Resistance Strength Tester Tear Strength Test Equipment Machine Burst TesterUS$ 2000 - 3000MOQ: 1 Set

-

Elmendorf Paper Tearing Bursting Strength Test EquipmentUS$ 2000 - 3000MOQ: 1 Set

-

Temperature and Humidity Adhesive Tape Retentivity TesterUS$ 8750 - 12500MOQ: 1 Set

-

Laboratory Packaging Drop Double Wing Drop Test MachineUS$ 3000 - 5500MOQ: 1 Set

-

Computer Servo Control Carton Compression Testing MachineUS$ 2900 - 5500MOQ: 1 Set

-

Paper Package Clamp Compression Machine Cardboard Clamp Force Testing EquipmentUS$ 6000 - 12000MOQ: 1 Set