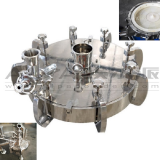

Lithium Cobalt Oxide Powder Disc Jet Mills Air Jet Mill Micronizer for Sale

Lithium Cobalt Oxide Powder Disc Jet Mills Air Jet Mill Micronizer for Sale

Widely used in chemical, pharmaceutical, cosmetics, intermediates, food and other industries.

1.Available particle size D50:1.5-45μm, mostly suitable for depolymerization;

2.The jet mill is suitable for dry grinding of various materials with Moh’s hardness below 9, especially for the materials with high hardness, high purity and high added value;

3.The grinding process is completed by the collision of the materials themselves., Fully self-grinding, So The device is durable and the purity of products is high in contrast;

4.Key parts like inner liner, classifying wheel and nozzle are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final product;

5.PLC control system, easy operation;

6.Optional explosion-proof design, can also be upgraded to nitrogen circulation system to meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials.

Disc Jet Mills Working Principle

MQP Spiral Jet Mill(Disc Jet Mill) works with cyclone separator, dust collector and suction fan to form a complete grinding system.

Compressed air flow after filtration and drying would go into milling chamber from nozzles, and meet in the center area, where material would be impacted and ground and sheared.

Milled powder would go up to the classifying chamber by the air flow from suction fan.

The high-speed rotation of classifier wheel would create a strong centrifugal force to separate coarse powder and fine powder.

Qualified fine powder would go through the wheel vane then into the cyclone separator or dust collector, while mixture of coarse powder and fine powder would fall down to the milling chamber to be milled again.

Lithium Cobalt Oxide Applications

Lithium cobalt oxide is one of the important components of lithium batteries. These lithium-ion batteries and their development products are common in the consumer electronics field. They are one of the most common types of rechargeable batteries in portable electronic devices, with high energy density, no memory effect, and only slow charge loss when not in use. In addition to consumer electronics, more and more advanced lithium-ion batteries are becoming more and more popular, which can be used in military, pure electric vehicles and aerospace applications.

(abbreviation: ALPA / Equity Code: 171033)

In the fields of ultrafine grinding and classification in the pharmaceutical, food, chemical, mineral, new materials, solid waste treatment and other industries, ALPA has mature and fully customized solutions and helps you design the ideal system to meet your needs.

Q: What service do you supply?

2). We supply sample processing tests in our test station where are equipped with our various machine products, to help clients compare performances of different types of machines or process.

3). We supply project engineering, automation engineering and civil engineering.

4). We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Q:How can I trust on your quality?

A: 1). All of the machine be tested successfully in Weifang workshop before shipment.

2). We supply one year warranty for all equipment and lifelong after-sales service.

3). We can test your material in our equipment before place the order, to ensure our equipment is suitable for your project.

4). Our engineers will go to your factory to install and debug the equipment, they will not be back until these equipment can produce qualified products.

Q:Does your company provide Engineers Abroad Service?

A: Sure, we provide it. And we can provide free training for on-site workers.

Q:How to train our staff about operation and maintenance?

A: We will provide detailed technical instructive pictures to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.

Send Inquiry to This Supplier

You May Also Like

-

Barite Powder Grinding Air Jet Mill Machine for 2-45microns Ultrafine GrindingUS$ 19999 - 80000MOQ: 1 Set

-

Silicon Powder High Purity Ultrafine Grinding Production Line Air Jet MillUS$ 10000 - 90000MOQ: 1 Set

-

2-150 Microns Powder Milling Systems Fluidized Bed Opposed Jet Mill for SaleUS$ 10000 - 90000MOQ: 1 Set

-

1.5-150 Micron Powder Grinding Pulverizer Fluidized Bed Spiral Jet Mill MicronizationUS$ 10000 - 90000MOQ: 1 Set

-

Ultrafine Grinding Technology Milling Particle Size Micronizer Jet MillUS$ 9999 - 90000MOQ: 1 Set

-

Boron Nitride Powder Making Machine Fluidized Bed Opposed Jet Mill MicroniserUS$ 9999 - 90000MOQ: 1 Set

-

Silicon Oxide Powder Ultrafine Grinding Micronizer Jet MillUS$ 9999 - 90000MOQ: 1 Set

-

White Carbon Black Ultrafine Grinding High Purity Steam Air Jet MillUS$ 9999 - 90000MOQ: 1 Set

-

Calcite Powder Grinding Machine ACM Air Classifying MillUS$ 9999 - 90000MOQ: 1 Set

-

Sulfur Powder ACM Grinding Machine Air Classifier Mill MachineryUS$ 9999 - 90000MOQ: 1 Set