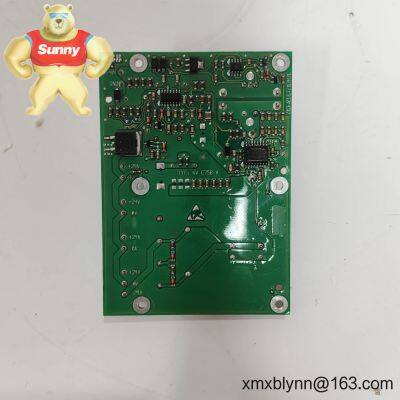

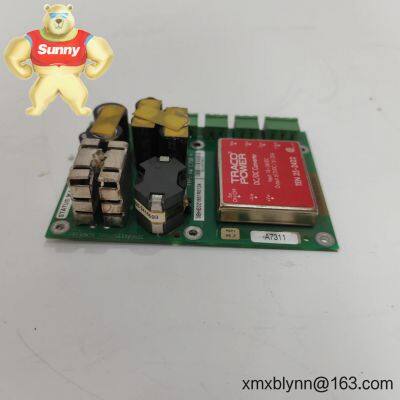

ABB 3BHE021951R0124 – OEM Control Board Module for ABB Industrial Drive and Control Systems

The ABB 3BHE021951R0124 is an original ABB board-level spare, typically used inside ABB drive/control cabinets as a plug-in controller or interface module. It’s designed for fast field replacement and stable operation in demanding process environments where downtime carries a real cost. From my experience, sites keep at least one unit on hand to shorten MTTR during unplanned stops.

Genuine ABB spare part – Ensures mechanical fit, electrical compatibility, and predictable behavior with existing ABB systems.

Plug-in form factor – Designed for quick swap-out in the control rack/backplane, minimizing production interruption.

Industrial-grade components – Built for cabinet environments with electrical noise, vibration, and 24/7 duty cycles.

Firmware/parameter compatibility – In most cases, revision-matched for straightforward commissioning with existing configurations.

Traceability – ABB part/serial labeling supports lifecycle management and maintenance recordkeeping.

| Brand / Model | ABB 3BHE021951R0124 |

| Product Type | Control/Interface PCB (OEM spare part) |

| Power Requirements | Supplied via host system backplane (24 VDC control power is typical) |

| Signal I/O | Depends on system configuration; usually includes board-edge and backplane connections specific to the target ABB platform |

| Communication | Platform-dependent (verify by board revision and installed system; may require firmware alignment) |

| Installation Method | Plug-in/rack-mounted inside ABB control/drive cabinet with ESD-safe handling |

| Operating Environment | Clean, ventilated cabinet; typical industrial control ambient (many sites run 0–55°C with non-condensing humidity) |

This model is commonly used as a service replacement in ABB drive and control platforms operating in continuous process industries. You might notice that maintenance teams prefer it for:

Steel, cement, and mining lines where medium-to-high power drives are critical

Pulp & paper, chemicals, and water treatment with 24/7 duty cycles

Oil & gas, marine, and utility applications requiring stable, deterministic control

One maintenance supervisor told us they swapped a 3BHE021951R0124 during a scheduled micro-stop and had the line back within 30 minutes, mostly because the board fit exactly and parameters synced without surprises.

Reduced downtime – Drop-in compatibility speeds changeover, which in many cases is the main cost driver.

Lifecycle alignment – Matches ABB’s hardware/firmware ecosystem, helping avoid integration quirks seen with non-OEM parts.

Reliable sourcing – Traceable manufacturing and known revisions; easier compliance with site QA procedures.

Total cost control – Predictable maintenance planning and less engineering time during commissioning.

Pre-checks: Confirm model 3BHE021951R0124 against your BOM and controller firmware. Back up parameters and recipes before any swap.

Cabinet environment: Maintain clean airflow, proper grounding, and stable 24 VDC control power. Avoid conductive dust; verify shielding/earthing.

Handling: Use ESD protection. Seat the board fully in the backplane and secure latches/screws. If fiber or keyed connectors are present, check orientation.

Commissioning: Power up, load or verify configuration, then run built-in diagnostics. Observe status LEDs and alarm logs for a few cycles.

Routine care: Keep filters clean, inspect connectors annually, and schedule firmware updates when recommended by ABB for your platform.

Spares strategy: Stock one unit per critical cabinet, especially for lines with tight OEE targets. It seems to be the pragmatic approach many plants take.

Manufactured under ABB’s quality system (ISO 9001); environmental management typically aligned to ISO 14001.

RoHS compliance generally applies to current revisions; confirm by part label if your site requires formal documentation.

CE/UL conformity is handled at the complete system level; this board is supplied as a service spare for ABB platforms.

Warranty: commonly 12 months from shipment for new units; terms may vary by supply channel and region.

Send Inquiry to This Supplier

You May Also Like

-

ABB 3BHE033067E0102 – Control/Interface Board for ABB Industrial Drive SystemsNegotiableMOQ: 1 Combo

-

ABB 3BHE033067R0103 – Control/Interface Board for ABB Drive and Control CabinetsNegotiableMOQ: 1 Combo

-

ABB 3BHE027632R0101 – Industrial Control PCB for Drive and Excitation PlatformsNegotiableMOQ: 1 Combo

-

ABB 3BHE033068P106 – Control Board Assembly for ABB Drive and Excitation SystemsNegotiableMOQ: 1 Combo

-

ABB 3BHE050077R0102 – Industrial Control Module for Drive and Automation SystemsNegotiableMOQ: 1 Combo

-

ABB 3BHL000382P0101 GVC700AE01 – IGCT Gate Unit for Medium-Voltage Drive and Converter StacksNegotiableMOQ: 1 Combo

-

ABB 3BHL000384P0101 – Control/Interface Board for ABB Low-Voltage DrivesNegotiableMOQ: 1 Combo

-

ABB 3BHL000392P0001 IGCT Module – Press-pack Power Device for Medium-voltage Drive StacksNegotiableMOQ: 1 Combo

-

ABB 3BHL000986P3105 IGCT Thyristors Module – Robust Medium-voltage Switching for Drives and ConvertersNegotiableMOQ: 1 Combo

-

ABB 3BSC980004R784 – 800xA / AC 800M System Spare for Dependable Process UptimeNegotiableMOQ: 1 Combo