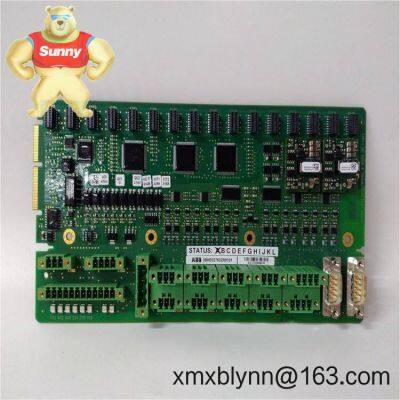

ABB 3BHE027632R0101 – Industrial Control PCB for Drive and Excitation Platforms

The ABB 3BHE027632R0101 is an original OEM control board used inside ABB drive and excitation cabinets, typically as a core interface for I/O processing and system coordination. From my experience, it’s specified as a direct, drop‑in replacement in installed bases where uptime matters, helping maintenance teams restore functionality fast without re-engineering the cabinet.

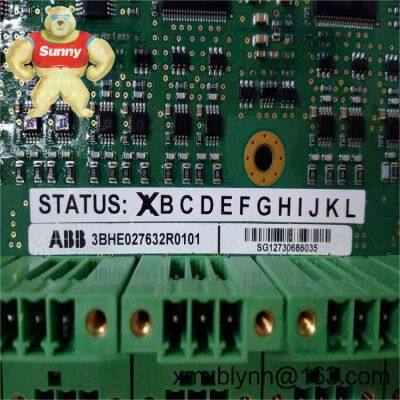

You might notice that the R0101 suffix denotes a defined hardware revision, which usually signals stable compatibility across the same platform generation. That consistency is exactly what many service teams are looking for during planned outages.

OEM-grade replacement: Ensures form, fit, and function in ABB cabinets with no mechanical modifications.

Stable signal handling: Designed for reliable analog/digital I/O processing and control logic in demanding environments.

Galvanic isolation where required: Helps protect upstream controllers and field wiring, reducing nuisance trips.

Conformal coating (commonly found on ABB boards): Adds environmental robustness against dust and humidity.

On-board diagnostics indicators: LEDs typically aid fault tracing and quick power-up checks.

Consistent revision control (R0101): Aids lifecycle planning and simplifies spares standardization.

| Brand / Model | ABB 3BHE027632R0101 |

| Form Factor | Board-level control module for installation inside ABB drive/excitation cabinets |

| Power Requirements | 24 VDC control power (typical for ABB control boards; check system rating) |

| Operating Temperature | Typically 0 to +55 °C, cabinet/environment dependent |

| Signal I/O | Backplane and header connections for analog/digital I/O, as defined by host system |

| Communication Interfaces | Platform-specific (often backplane bus and/or fiber link in ABB systems) |

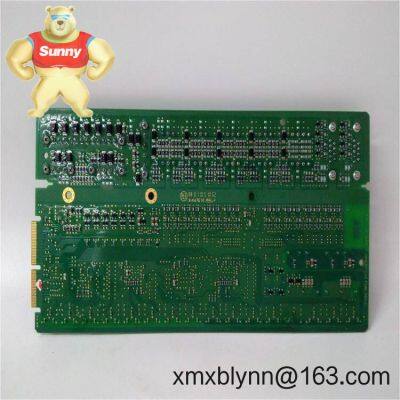

| Installation Method | Slides into card guides or mounts on standoffs within the original cabinet location |

In many cases, the 3BHE027632R0101 is deployed in ABB platforms tied to heavy-duty applications where downtime costs real money. Typical environments include:

Drive cabinets for process lines in metals, paper, and chemicals

Excitation and rectifier systems in power generation and utility substations

Marine propulsion and large pumping systems

Mining conveyors, hoists, and material handling rigs

Reliability that maintenance teams trust: Built for 24/7 operation in harsh cabinets, with the right isolation and noise immunity.

Compatibility and faster recovery: Drop-in fit helps avoid rewiring or PLC logic changes in most retrofit scenarios.

Cost control: Replacing a failed board typically saves far more than swapping an entire drive or excitation rack.

Serviceability: Clear labeling and status LEDs make fault-finding quicker, so crews can move on to production sooner.

A maintenance supervisor told us their team swapped this board during a scheduled stop on a mill stand, powered back up, and the unit went green immediately—no parameter chase, no re-commissioning hassle. Not every case is that smooth, but it’s a good reference point.

Installation & MaintenanceCabinet conditions: Follow ABB cabinet standards—clean, dry enclosure with adequate ventilation; avoid conductive dust.

ESD practice: Handle the PCB with grounding strap and ESD-safe packaging; avoid touching component leads.

Wiring and seating: Use existing harness/backplane connectors; ensure full seating in card guides and secure fasteners.

Firmware/parameter alignment: Match board revision and firmware to the host system where applicable, then verify I/O mapping.

Routine care: Periodic dust removal with dry air (low pressure), connector inspection, and check diagnostic LEDs during startups.

Safety: Isolate control power and wait for discharge times before handling; follow site LOTO procedures.

CE-marked and RoHS compliant components typical for ABB control boards

Manufactured under ISO 9001 quality systems

UL compliance applicable to the overall system/cabinet in many installations

Standard manufacturer warranty: typically 12 months from shipment, subject to terms

Note: Specific interfaces and ratings can vary by platform and firmware package. If you’re matching a failed unit, cross-check the full part code and revision against your system’s parts list.

Send Inquiry to This Supplier

You May Also Like

-

ABB 3BHL000986P3105 IGCT Thyristors Module – Robust Medium-voltage Switching for Drives and ConvertersNegotiableMOQ: 1 Combo

-

ABB 3BSC980004R784 – 800xA / AC 800M System Spare for Dependable Process UptimeNegotiableMOQ: 1 Combo

-

ABB 3BSE018126R1 – Original ABB Module for 800xA/AC 800M and S800 I/O SystemsNegotiableMOQ: 1 Combo

-

ABB 3BSE024387R4 – S800 I/O System Component for ABB 800xA / AC 800M InstallationsNegotiableMOQ: 1 Combo

-

ABB 3BSE038415R1 AO810V2 – 8‑Channel Analog Output Module for S800 I/ONegotiableMOQ: 1 Combo

-

ABB 3HAC025338-006 – OEM Robot Cable Assembly for IRC5/IRB SystemsNegotiableMOQ: 1 Combo

-

ABB 3HNA025019-001 – Robotics Spare Part for IRC5/FlexPendant System MaintenanceNegotiableMOQ: 1 Combo

-

ABB 500AIM02 (1HDF 930412 X010) – Analog Input Module for ABB 500‑series Drive/Control PlatformsNegotiableMOQ: 1 Combo

-

ABB 500AIM02 (1MRB150022R001) – Multi‑channel Analog Input Module for 500‑series Control RacksNegotiableMOQ: 1 Combo

-

ABB 500BIM01 (1MRB150024R0002) – Binary Input Module for ABB 500‑series Control and Drive SystemsNegotiableMOQ: 1 Combo