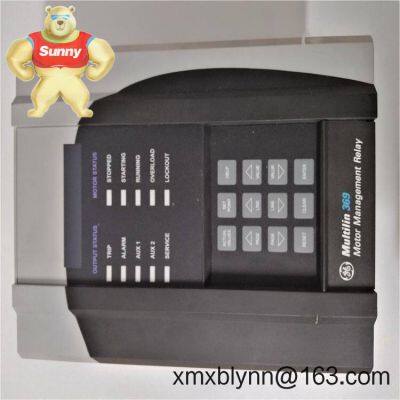

GE Multilin 369-HI-R-M-0-0-0-0 Motor Management Relay – High-range Control Power, RTD Thermal Monitoring, and Full Metering for Critical Motors

The GE Multilin 369-HI-R-M-0-0-0-0 is a proven motor management relay designed to protect and monitor medium and large AC motors in demanding industrial environments. With the “HI” high-range control power, the “R” RTD module, and the “M” metering package, this build gives maintenance and operations teams a solid blend of protection, diagnostics, and power-quality insight—without adding optional fieldbus cards you may not need.

From my experience, this configuration fits well on pumps, fans, compressors, and conveyors where thermal stress and process upsets can creep in unexpectedly. You might notice that it simplifies startup inhibit and jam/stall protection while giving you clean Modbus access for SCADA trending.

Key FeaturesHigh-range control power (HI) – Typically 70–265 Vac or 90–300 Vdc, so it rides through a wide utility or UPS footprint without an auxiliary supply.

Comprehensive motor protection – Thermal model overload, jam/stall, underload, phase loss/unbalance, ground fault, restart inhibition, and start-time supervision, covering most day-to-day risks.

RTD thermal monitoring (R) – Up to 12 RTD channels commonly used for stator, bearing, and ambient temperature tracking; typically supports Pt100 for precise thermal protection.

Full metering package (M) – Three-phase voltage inputs enable real-time V, kW, kVAR, PF, and energy; ideal for load studies and identifying mechanical issues masked as electrical.

Event and data logging – Time-stamped alarms and trips with trend data help teams pinpoint root causes faster, especially during intermittent faults.

Built-in RS-485 (Modbus RTU) – Straightforward integration to PLC/SCADA systems; this specific build omits optional Ethernet/fieldbus cards for a simpler, cost-conscious deployment.

Rugged, panel-mounted design – Fits neatly on cabinet doors, with rear terminal wiring; typically used in MCC buckets or standalone motor panels.

| Brand / Model | GE Multilin 369-HI-R-M-0-0-0-0 Motor Management Relay |

| Function | Protection, monitoring, and metering for three-phase AC motors |

| Control Power (HI) | Typically 70–265 Vac or 90–300 Vdc |

| Signal Inputs / Outputs | Three-phase current via CTs; three-phase voltage inputs (M option); up to 12 RTDs (R option); multiple digital inputs & relay outputs |

| Communication Interfaces | RS-485 (Modbus RTU). No optional Ethernet/Profibus/DeviceNet in this build (0-0-0-0) |

| Operating Temperature | −20°C to +60°C typical |

| Installation Method | Panel/cabinet door mount; rear terminal connections; suited for MCC applications |

| Dimensions & Weight | Standard 369 form factor; refer to the datasheet for exact cutout and weight |

| Approvals (typical) | CE, UL/cUL, CSA; RoHS where applicable |

The 369-HI-R-M is commonly deployed on low- and medium-voltage motors via CT/VT secondaries. It’s a practical fit for:

Water & wastewater – Sludge pumps, high-service pumps, aeration blowers; jam protection reduces unplanned callouts.

Oil & gas / Petrochemical – Booster pumps, cooling tower fans, compressor drives where thermal stress needs close watching.

Mining & aggregates – Conveyors and crushers; stall detection and underload help catch broken belts or blocked intakes.

Pulp & paper / Metals – Process motors where voltage metering and PF tracking can highlight power-quality problems early.

General manufacturing – HVAC and utility motors in MCCs; straightforward RS-485 links to existing PLCs.

Balanced feature set – RTDs plus voltage metering in one unit; in many cases this avoids separate temperature modules and stand-alone meters.

Lower integration effort – Native Modbus RTU keeps wiring simple; no need to wrestle with extra comms cards when you don’t need them.

Operational reliability – The high-range power supply tolerates typical plant variations, which seems to reduce nuisance dropouts.

Maintenance-friendly – Clear event logs and trending shorten troubleshooting time during startups or process upsets.

Total lifecycle cost – Consolidating protection and metering typically cuts panel space and future spares stocking.

“We used the 369-HI-R-M on two 250 kW process pumps. The jam detection saved a seal after debris got into the line, and the RTD channels finally gave us visibility on bearing temps.” — Maintenance Supervisor, food plant

Installation & MaintenancePanel and cabinet – Mount on a rigid, ventilated door or panel; maintain clearance for heat dissipation and service access.

Wiring practices – Use properly burdened CTs/VTs; keep RTD and control wiring separated from power to minimize noise; follow shield and grounding best practices.

Configuration – Set motor FLA, start profiles, jam/stall thresholds, RTD types (typically Pt100), and comms parameters before energization.

Safety – De-energize and verify isolation before servicing; observe arc-flash procedures in MCCs.

Routine checks – Review event logs quarterly, verify RTD readings against handheld measurements, clean vents, and apply firmware updates where available.

Commissioning tip – Trend voltage and current during the first week; abnormal PF drift often flags mechanical issues early.

Conforms to major industrial approvals such as CE and UL/cUL; CSA compliance is common for this series.

RoHS compliance is supported on most recent production, depending on region and date codes.

Manufacturer’s limited warranty (typically 2 years). Extended service and repair programs are often available.

If you’re standardizing on Modbus and need integrated RTD and metering without extra complexity, the 369-HI-R-M-0-0-0-0 is usually the sweet spot. If you later decide on Ethernet or a different fieldbus, the family supports variants with those options as well.

Send Inquiry to This Supplier

You May Also Like

-

GE 531X304IBDASG1 Inverter Bridge Driver Card – Reliable Gate Drive and Protection for GE Industrial DrivesNegotiableMOQ: 1 Combo

-

GE 531X305NTBANG1 Terminal Board – Reliable Field I/O Termination for GE Drive SystemsNegotiableMOQ: 1 Combo

-

GE 531X305NTBAPG1 – NTBA Terminal Board for Field I/O Termination in Legacy GE Drives and Control SystemsNegotiableMOQ: 1 Combo

-

GE 531X307LTBAHG1 LAN Terminal Board – Reliable Field I/O and LAN Termination for Legacy GE Drive SystemsNegotiableMOQ: 1 Combo

-

GE 531X307LTBAJG1 LAN Terminal Board – Reliable Field Wiring Interface for GE Drive NetworksNegotiableMOQ: 1 Combo

-

GE Multilin 750-P1-G1-S1-HI-A20-G – Feeder Protection Relay for Reliable MV/LV DistributionNegotiableMOQ: 1 Combo

-

GE PAC8000 8521-HC-MT – HART Maintenance Access for Remote Field I/ONegotiableMOQ: 1 Combo

-

GE LV5F30-NF – Low-voltage AC Drive for Reliable Motor Control in Pumps, Fans, and ConveyorsNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-0 – Motor Management Relay for Reliable Three‑Phase Motor ProtectionNegotiableMOQ: 1 Combo

-

GE Multilin 369-HI-0-M-0-E-0 Motor Management Relay – Intelligent Protection and Monitoring for Critical MotorsNegotiableMOQ: 1 Combo