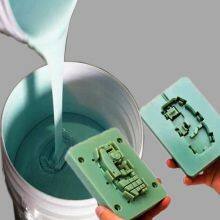

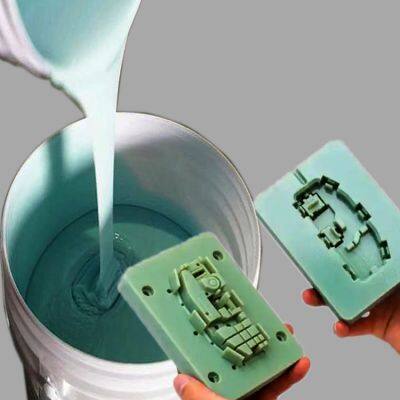

Customized Liquid Silicone Rubber for Complex Resin Mold Making and Mold Duplication. 20A Free Sample Production.

Order consultation for liquid silicone rubber: Contact the factory via WhatsApp: +86 13662816580

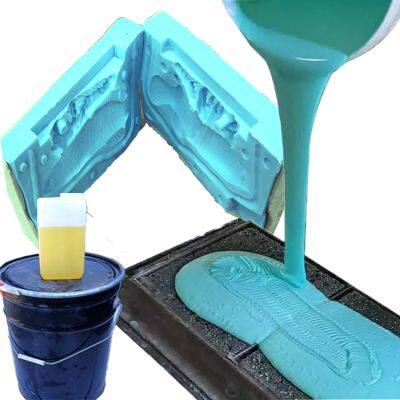

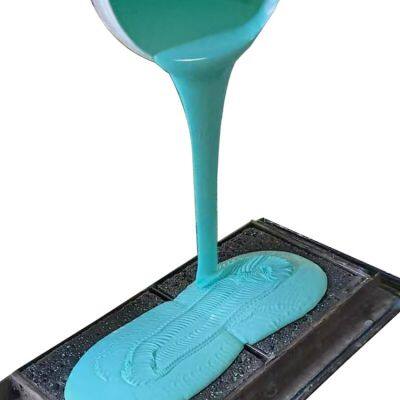

In the resin mold replication process, liquid silicone rubber is one of the core materials for making molds. It possesses excellent elasticity, replication accuracy, and demolding performance, enabling efficient batch or small-batch replication of complex resin products (such as figurines, handicrafts, industrial parts, etc.). The following provides a detailed introduction from aspects such as characteristics, types, usage process, and selection points:

1. Core characteristics of liquid silicone rubber used in resin mold replication

Liquid silicone rubber (LSR) is a two-component (A/B formulation) material composed of base rubber (containing silicone oil, silica, etc.) and crosslinking agents, catalysts, etc. After curing, it forms an elastic mold. The core reason why it is suitable for resin mold replication lies in:

High replication accuracy: Excellent fluidity (down to 500 mPa·s), capable of penetrating the fine textures on the surface of the prototype (such as patterns and inscriptions below 0.1mm), and completely replicating details after curing, especially suitable for complex shapes (such as hollowing, uneven textures, multi-surface structures).

Excellent demolding performance: After curing, the surface is smooth, has low compatibility with resins (epoxy resin, PU resin, unsaturated resin, etc.), and can be easily demolded without frequent use of demolding agents, reducing damage to the product surface.

Chemical resistance compatibility: Has good corrosion resistance to most resins (especially neutral resins),due to the curing agent and solvent in the resin, prolonging the mold life.

Balance of elasticity and toughness: after curing is usually in the range of 10-60A (customizable), with adjustable softness and hardness — soft silicone rubber (10-30A) is suitable for thin-walled, easily deformed products for demolding; hard silicone rubber (40-60A) is suitable for large parts, high-hardness resins (such as epoxy resin), enhancing mold durability.

Operational convenience: After mixing the two components, it can be molded by pouring, brushing, spraying, etc., without the need for high-temperature and high-pressure equipment. It can cure at room temperature (around 25℃) without heating to accelerate the process, with a short production cycle (usually 4-24 hours for curing).

Send Inquiry to This Supplier

You May Also Like

-

Durable Candle Mold Silicone Rubber, With Low Shrinkage Rate, Raw Material for DIY Handmade MoldsUS$ 3.8MOQ: 50 Kilograms

-

Special Materials for Wall Tiles, Cement Components and Moldings RTV2 Two-component Silicone Rubber - Low Shrinkage and Easy to HandleUS$ 3.8MOQ: 50 Kilograms

-

The Cement Component Mold is Preferably Manufactured With AB Liquid Silicone Rubber, Which is Corrosion-resistant, Tear-resistant and Easy to Demold.US$ 3.8MOQ: 50 Kilograms

-

High-quality RTV2 Silicone Rubber Composite Material for Manufacturing Cement Wall TilesNegotiableMOQ: 3 Kilograms

-

Composite Material Liquid Silicone Rubber is Used for Manufacturing Mold Carving and Mold DuplicationNegotiableMOQ: 3 Kilograms

-

Solder-cured Liquid Silicone Rubber - Special Glue for Decorative Model Molds - Room Temperature Curing With Low ShrinkageUS$ 3.8MOQ: 50 Kilograms

-

Decorative Model Mold Tin-cured Liquid Silicone Rubber. It Sets Quickly at Room Temperature. Free Sample Available.US$ 3.8MOQ: 50 Kilograms

-

The AB Two-component Flowerpot Casting Silicone Rubber Liquid Mold Material Cures Quickly and the Details Are Well RestoredUS$ 4.5MOQ: 1 Kilogram

-

DIY Flower POTS, AB Two-component Liquid Mold Silicone Rubber Suitable for Cement Resin Material, Easy DemoldingUS$ 4.5MOQ: 1 Kilogram

-

A Must-have for DIY Candles! The Liquid Silicone Rubber Mold Material is Easy to Operate and DemoldUS$ 3.8MOQ: 1 Kilogram