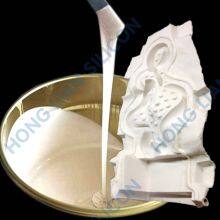

Special Materials for Wall Tiles, Cement Components and Moldings RTV2 Two-component Silicone Rubber - Low Shrinkage and Easy to Handle

Special materials for wall tiles, cement components and moldings RTV2 Two-component Silicone Rubber - Low Shrinkage and Easy to Handle

If you need any information about RTV2 liquid silicone rubber, please contact us via WhatsApp at +86 13662815680.

The wall tile and cement component molds are manufactured using RTV two-component silicone rubber because it possesses several characteristics suitable for this application scenario. The details are as follows:

Excellent fluidity: After mixing, the RTV two-component silicone rubber has excellent fluidity, which can automatically fill all corners of the mold. For complex-shaped and detailed wall tile and cement components, it can precisely replicate their appearance and details, such as patterns, lines, etc.

Low shrinkage rate: Its shrinkage rate can be controlled within 0.1%-0.3%, ensuring the dimensional accuracy of the mold, resulting in stable dimensions of the produced wall tile and cement components that meet design requirements and reducing dimensional deviations caused by mold shrinkage.

High tear resistance: The RTV two-component silicone rubber has a high tear resistance, and it is not easily damaged during demolding, capable of withstanding multiple demolding operations, thereby increasing the lifespan of the mold and reducing production costs.

Corrosion resistance: Cement during the curing process produces alkaline substances, and the RTV two-component silicone rubber has good acid and alkali resistance, capable of resisting the alkaline corrosion of cement, ensuring the performance and lifespan of the mold.

Simple operation: RTV two-component silicone rubber usually cures and solidifies at room temperature, requiring no heating or pressurization equipment. Just mix the A and B components in a certain proportion evenly and proceed with the pouring or mold application operation. The operation process is simple and easy for workers to master.

High simulation performance: After curing, the silicone rubber has good elasticity and flexibility, capable of realistically replicating the shape and details of the original model. The produced molds can produce wall tile and cement components almost identical to the prototype.

Adjustable curing time: By adjusting the dosage of the curing agent, the curing time of the RTV two-component silicone rubber can be controlled, meeting the needs of different production rhythms and improving production efficiency.

Send Inquiry to This Supplier

You May Also Like

-

The AB Two-component Flowerpot Casting Silicone Rubber Liquid Mold Material Cures Quickly and the Details Are Well RestoredUS$ 4.5MOQ: 1 Kilogram

-

DIY Flower POTS, AB Two-component Liquid Mold Silicone Rubber Suitable for Cement Resin Material, Easy DemoldingUS$ 4.5MOQ: 1 Kilogram

-

A Must-have for DIY Candles! The Liquid Silicone Rubber Mold Material is Easy to Operate and DemoldUS$ 3.8MOQ: 1 Kilogram

-

A Handcrafted Magic Tool for Candle Molds Made of Silicone Rubber That is Easy to Remove and Heat-resistantUS$ 3.8MOQ: 1 Kilogram

-

High-elasticity Candle Mold Making Liquid Silicone Rubber Vulcanization at Room TemperatureUS$ 4MOQ: 50 Kilograms

-

Candle Model-specific Liquid Silicone Rubber Two-component AB Glue is Easy to Demold Without BubblesUS$ 4MOQ: 50 Kilograms

-

Figurine/resin Handicraft Mold, Liquid Mold, Silicone Rubber, Fine Texture, High Fidelity, Softness and Hardness SelectableUS$ 3.5MOQ: 1 Kilogram

-

Special Liquid Mold Silicone for Candles/gypsum Products, Easy Demolding, no Residue, and Rapid Curing at Room TemperatureUS$ 3.5MOQ: 1 Kilogram

-

Room-temperature Vulcanized Silicone Rubber for Architectural Models,Low Shrinkage Rate and Multiple Moldings RequiredNegotiableMOQ: 50 Kilograms

-

High and Low Temperature Resistant RTV2 Liquid Silicone Rubber - Specially for Mold Carving and Mold Making - Does Not Deform After Multiple UsesNegotiableMOQ: 50 Kilograms