Special Silicone RTV2 Flowable Silicone Rubber for European Component Molds The Service Life of the Mold is 50 or More Times.

Special silicone RTV2 flowable silicone rubber for European component molds The service life of the mold is 50 or more times.

Inquiry about the purchase of RTV2 silicone rubber: WhatsApp: +86 13662816580

In the mold-making process of European-style components (such as plaster lines, relief ceiling panels, Roman column decorations, etc.), RTV2 silicone rubber is widely used due to its good fluidity, high replication accuracy, excellent elasticity, and excellent aging resistance. The operation process can be divided into the following steps: pre-preparation, prototype processing, silicone rubber mixing, injection/masking, curing, demolding, and mold adjustment. Here are the detailed methods and precautions:

1. Preparations: Clarify requirements and materials/tools

1. Core materials selection

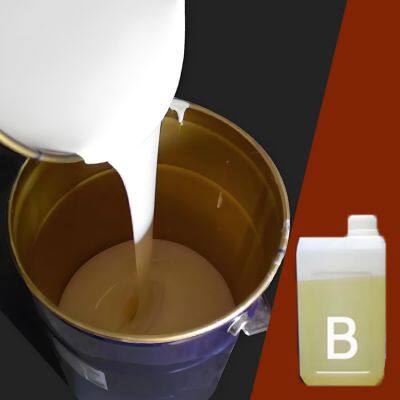

RTV2 silicone rubber: Select the model based on the size and complexity of the component. For small and precise components, choose the high-flow type (for easy filling of details); for large components, choose the high-hardness type (combined with reinforcing materials to enhance strength). The common hardness range is Shore A 20-50.

Auxiliary materials:

Curing agent (RTV2 B component, mixed with A component in a certain ratio, usually 10:1 or 5:1, strictly follow the instructions);

Demolding agent (Vaseline, silicone oil, special demolding wax, to avoid silicone rubber adhering to the prototype);

Reinforcing materials (glass fiber cloth, glass fiber mat, used for large molds to resist tearing);

Mold frame (wooden board, PVC board made, to fix the prototype and limit the flow range of the silicone rubber).

Send Inquiry to This Supplier

You May Also Like

-

High-quality RTV2 Silicone Rubber Composite Material for Manufacturing Cement Wall TilesNegotiableMOQ: 3 Kilograms

-

Composite Material Liquid Silicone Rubber is Used for Manufacturing Mold Carving and Mold DuplicationNegotiableMOQ: 3 Kilograms

-

Solder-cured Liquid Silicone Rubber - Special Glue for Decorative Model Molds - Room Temperature Curing With Low ShrinkageUS$ 3.8MOQ: 50 Kilograms

-

Decorative Model Mold Tin-cured Liquid Silicone Rubber. It Sets Quickly at Room Temperature. Free Sample Available.US$ 3.8MOQ: 50 Kilograms

-

The AB Two-component Flowerpot Casting Silicone Rubber Liquid Mold Material Cures Quickly and the Details Are Well RestoredUS$ 4.5MOQ: 1 Kilogram

-

DIY Flower POTS, AB Two-component Liquid Mold Silicone Rubber Suitable for Cement Resin Material, Easy DemoldingUS$ 4.5MOQ: 1 Kilogram

-

A Must-have for DIY Candles! The Liquid Silicone Rubber Mold Material is Easy to Operate and DemoldUS$ 3.8MOQ: 1 Kilogram

-

A Handcrafted Magic Tool for Candle Molds Made of Silicone Rubber That is Easy to Remove and Heat-resistantUS$ 3.8MOQ: 1 Kilogram

-

High-elasticity Candle Mold Making Liquid Silicone Rubber Vulcanization at Room TemperatureUS$ 4MOQ: 50 Kilograms

-

Candle Model-specific Liquid Silicone Rubber Two-component AB Glue is Easy to Demold Without BubblesUS$ 4MOQ: 50 Kilograms