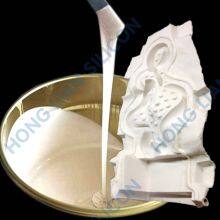

Special Silicone RTV2 Two-component Mold Adhesive for Large-scale European-style Component Moldings Relief Mold Making Mold Glue

Special silicone RTV2 two-component mold adhesive for large-scale European-style component moldings Relief mold making mold glue

Order inquiry for liquid silicone rubber contact via WhatsApp: +86 13662816580

RTV2 Silicone Rubber Mixing: Key to Influencing Mold Performance

1. Mix A and B components in proportion

Mix according to the specified ratio (e.g. 100:2), weigh A component (base rubber) and B component (curing agent) accurately using clean containers. Avoid deviation in proportion (excessive curing agent will cause the mold to become brittle, while insufficient will result in incomplete curing).

Stir in the same direction during mixing, do not stir too fast (to avoid the generation of a large number of bubbles), and let the mixing time be ≥ 3 minutes to ensure uniform color (no white spots or stripes).

2. Defoaming treatment

Manual small batch: After mixing, let it stand for 5-10 minutes, gently stir with a glass rod to allow the surface bubbles to rise and burst;

Batch production: Use a vacuum defoaming machine (vacuum degree - 0.09MPa) to treat for 2-3 minutes until all bubbles disappear (be careful to avoid silicone rubber overflow).

Key: Complex detailed components must be defoamed; otherwise, the mold will have bubble holes, affecting the accuracy of the finished product.

IV. Injection / Brushing: Choose the process based on the shape of the component

1. Injection method (suitable for small, three-dimensional components, such as stem head decorations, relief small items)

Pour the defoamed silicone rubber slowly along the edge of the mold frame, do not pour too fast (to avoid entrapping bubbles), until the silicone rubber completely covers the prototype, thickness ≥ 1cm (the edges can be slightly thicker to enhance it).

If the prototype has deep grooves, small holes, etc., fill them with a small amount of silicone rubber manually first, then pour the entire silicone rubber, and gently brush the details with a brush to remove the bubbles.

After pouring, gently tap the mold frame or flat plate to allow the bubbles to float to the surface and burst.

2. Brushing method (suitable for large, flat / curved components, such as plaster lines, wall relief)

Step 1: Brush the "detail layer" - Take a small amount of silicone rubber, evenly apply it to the prototype surface, focus on filling the detailed areas thoroughly, thickness about 0.5mm.

Step 2: Reinforcement layer - After the detail layer is semi-cured (about 30 minutes, not sticky to the hand), lay a layer of fiberglass cloth (cut to the size of the mold frame), use a brush dipped in silicone rubber to press the cloth down, avoid wrinkles and bubbles.

Step 3: Thickening layer - Repeat the layering and brushing 2-3 times, total thickness controlled at 3-5mm (adjust according to the size of the component), ensure the overall strength of the mold, edges can be appropriately thickened to 10mm.

Send Inquiry to This Supplier

You May Also Like

-

Composite Material Liquid Silicone Rubber is Used for Manufacturing Mold Carving and Mold DuplicationNegotiableMOQ: 3 Kilograms

-

Solder-cured Liquid Silicone Rubber - Special Glue for Decorative Model Molds - Room Temperature Curing With Low ShrinkageUS$ 3.8MOQ: 50 Kilograms

-

Decorative Model Mold Tin-cured Liquid Silicone Rubber. It Sets Quickly at Room Temperature. Free Sample Available.US$ 3.8MOQ: 50 Kilograms

-

The AB Two-component Flowerpot Casting Silicone Rubber Liquid Mold Material Cures Quickly and the Details Are Well RestoredUS$ 4.5MOQ: 1 Kilogram

-

DIY Flower POTS, AB Two-component Liquid Mold Silicone Rubber Suitable for Cement Resin Material, Easy DemoldingUS$ 4.5MOQ: 1 Kilogram

-

A Must-have for DIY Candles! The Liquid Silicone Rubber Mold Material is Easy to Operate and DemoldUS$ 3.8MOQ: 1 Kilogram

-

A Handcrafted Magic Tool for Candle Molds Made of Silicone Rubber That is Easy to Remove and Heat-resistantUS$ 3.8MOQ: 1 Kilogram

-

High-elasticity Candle Mold Making Liquid Silicone Rubber Vulcanization at Room TemperatureUS$ 4MOQ: 50 Kilograms

-

Candle Model-specific Liquid Silicone Rubber Two-component AB Glue is Easy to Demold Without BubblesUS$ 4MOQ: 50 Kilograms

-

Figurine/resin Handicraft Mold, Liquid Mold, Silicone Rubber, Fine Texture, High Fidelity, Softness and Hardness SelectableUS$ 3.5MOQ: 1 Kilogram