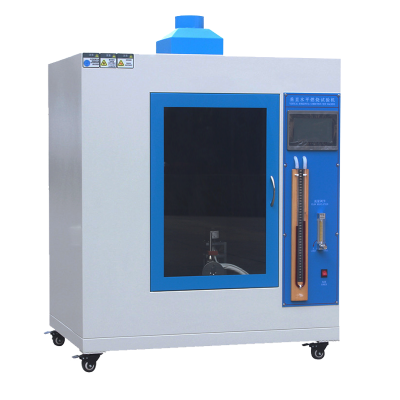

Vertical Combustion Tester CE Marked for EU Market Compliance

STANDARD FEATURES

Burning Chamber Capacity | ≥0.75m³ with glass observation door |

Burning Angle | 20 。, 45 。, 90 。 (ie 0 。) adjustable |

Flame Time | 0 ~ 99 minutes 99 seconds can be set |

After Flame Time | 0 ~ 99 minutes 99 seconds can be set |

After Glow Time | 0 ~ 99 minutes 99 seconds can be set |

Burner Dimensions | The inner diameter of the nozzle is Ø9.5±0.3mm, the effective length of the nozzle is 100±10mm, and there is an air adjustment hole |

Combustion Gas | LPG gas (Customize) |

Flame Height | Adjustable from 20mm to 175mm as standard |

Features | It is also equipped with lighting device, air extraction device, gas flow regulating valve, gas pressure gauge, gas pressure regulating valve, gas flow meter, gas U-shaped pressure gauge and sample fixture |

Power | AC 220v 50HZ |

Vertical Flame Tester with CE marking: meets EU market access requirements

I. Product Overview

The Vertical Flame Tester with CE certification is a precision device designed to evaluate the burning performance of various materials when exposed to a small flame ignition source. It is capable of simulating burning conditions in actual use, providing a reliable assessment of a material's fire performance. Through rigorous testing, the equipment helps to ensure that the materials meet the EU market access requirements, which is an important reference for the flame retardant performance of materials.

Testing Standards and Methods

The equipment is mainly tested according to the following standards:

IEC 60695: Fire hazard test standard developed by the International Electrotechnical Commission, covering a variety of test methods, including the scorch wire/hot wire based test and the small flame test.

EN 50379: European standard that specifies test methods and requirements for the combustion performance of wire and cable materials.

UL 94: Underwriters Laboratories' flammability test standard for plastic materials, widely used in the electrical and electronic industry.

Application Areas

Electrical and electronic industry: testing the flame retardancy of electronic equipment shells, circuit boards and other materials.

Building materials industry: Evaluate the flame retardancy of insulation materials and engineering plastics.

Automobile manufacturing industry: Flame retardant testing of automobile interior materials to improve the safety of vehicles.

Plastic industry: Evaluate the flame retardancy of various plastic materials.

Product Advantages

High precision: Equipped with precise gas control system and high sensitivity sensor to ensure the accuracy and repeatability of test results.

High degree of automation: equipped with automatic ignition, timing, recording data and other functions to reduce human error and improve testing efficiency.

Safe and Reliable: Designed with safety protection mechanisms such as fireproof board, fireproof window and leakage protection to guarantee the safety of operators and equipment.

Easy to operate: adopting intuitive touch screen interface, providing friendly operation experience, so that users can get started quickly.

V. Operation Process

Sample Preparation: Prepare the test samples according to the standard requirements to ensure that their size and thickness comply with the regulations.

Equipment Calibration: Calibrate the equipment before testing to ensure that all parameters are set correctly.

Environmental control: Perform the test under the specified temperature and humidity conditions to ensure the accuracy of the results.

Test Execution: Hang the sample vertically in the tester, apply the flame according to the standard requirements, and observe and record the burning situation.

Evaluation of results: Judge whether the material complies with the relevant standards according to the test results, focusing on checking the combustion time and drippings.

VI. Conclusion

The Vertical Combustion Tester with CE certification is an ideal tool to ensure the flame retardancy of materials. It provides accurate data support for R&D and quality control by simulating a real burning environment. Choosing our products is choosing the precise control of material combustion performance and strict quality control of products.

Send Inquiry to This Supplier

You May Also Like

-

Image Measuring Instrument for Aerospace Composite Material AnalysisUS$ 3000 - 5000MOQ: 1 Set

-

Image Measuring Instrument for Aerospace Composite Material AnalysisUS$ 3000 - 5000MOQ: 1 Set

-

Image Measuring Instrument for Aerospace Composite Material AnalysisUS$ 3000 - 5000MOQ: 1 Set

-

Image Measuring Instrument for Glass & Optics Surface Defect DetectionUS$ 3000 - 5000MOQ: 1 Set

-

Digital Hardness Tester for Metal/Rockwell/HRC With LCD Screen & CE CertificateUS$ 2000 - 3000MOQ: 1 Set

-

High Precision Brinell Hardness Tester Machine for Steel Alloy - Free ShippingUS$ 2000 - 3000MOQ: 1 Set

-

Auto-Rotary Vickers Hardness Tester With 0.1μm Resolution & Data ExportUS$ 2000 - 3000MOQ: 1 Set

-

Lab-Use Micro Hardness Tester With 50X Lens & 99 Groups Data StorageUS$ 2000 - 3000MOQ: 1 Set

-

Multi-Function Hardness Testing Machine for Metal Sheets/Bars/TubesUS$ 2000 - 3000MOQ: 1 Set

-

Multi-Function Hardness Testing Machine for Metal Sheets/Bars/TubesUS$ 2000 - 3000MOQ: 1 Set