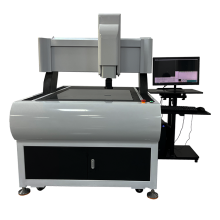

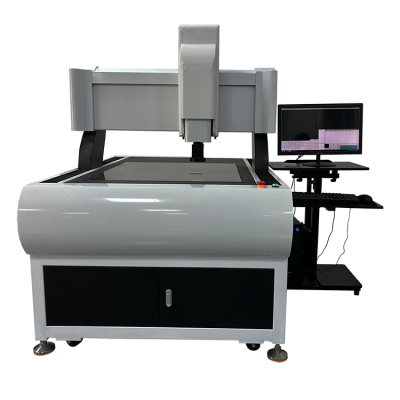

Image Measuring Instrument for Automotive Component Dimensional Control

Technical parameter:

Model | DR-G301 | DR-G301-1 | DR-G301-2 | |

Table | Metal table size(mm) | 340 × 152 | 350×170 | 450 × 280 |

Glass table size(mm) | 196 × 96 | 246× 120 | 306× 196 | |

X coordinate travel (mm) | 150 | 200 | 250 | |

Y coordinate travel (mm) | 50 | 100 | 150 | |

Z coordinate travel (mm) | 90(Focusing) | 100( Focusing ) | 100( Focusing ) | |

Measuring accuracy (μm) | 3+L/50 | 3+L/75 | 3+L/75 | |

X, Y Block, Digital Resolution | 0.001mm | |||

Projection screen | Size (mm) | Ø312, Terms of Use>Ø300( Engraved with the word line m ) | ||

Rotation range | 0~360° | |||

Rotation Digital Resolution | 1' or 0.01° | |||

Mirror Matter | Magnification | 10X( Necessary ) 20X(Option) 50X ( Option ) 100X ( Option ) | ||

Line field of view in object (mm) | Ø30 Ø15 Ø6 Ø3 | |||

Work in object distance (mm) | 77.7 44.3 24.5 25.3 | |||

Data Processor | DC-3000 multi-function data processing system, all the Chinese showed they can do more sampling, coordinate rotation, point, line, distance, angle measurement | |||

Instrument lighting | Transmission and reflection of light source are: 24V, 150W halogen lamp | |||

Instrument Power | 110V/ 220V(AC), 50/60HZ, Total power 400W | |||

Cooling method | Forced air-cooled (3 axial fans) | |||

Dimensions | L × W × H (mm) | 792× 544 × 975 | 770 × 550× 1120 | 770 ×550× 1120 |

Weight | Unit Kg | 150 | 150 | 150 |

Options | Micro-printer, optical Edge Detector, M2D software; detailed description see Annex projector. | |||

PCB circuit board inspection image measuring instrument: the perfect combination of precision measurement and efficient inspection

In the field of modern electronics manufacturing, the quality control of PCB circuit boards is crucial. As an advanced precision measurement tool, image measuring instrument provides an efficient and accurate solution for PCB circuit board inspection. This article will provide you with a detailed introduction to the unique advantages and application value of this instrument.

I. Product Overview

PCB circuit board inspection image measuring instrument is a set of optical imaging, image processing and precision measurement technology in one of the high-precision testing equipment. It is capable of non-contact measurement of tiny parts and complex lines on circuit boards, realizing precise evaluation of size, shape, position and other parameters. Through advanced image measurement technology, the instrument can quickly capture the image of the circuit board and analyze the data with professional measurement software, thus providing a reliable basis for quality control and process optimization.

Second, the technical parameters

Optical system: Equipped with high-resolution optical lens and advanced lighting system to ensure clear imaging.

Sensor: High pixel CCD or CMOS sensor is used to capture high quality images.

Measuring range: Depending on the model, it can cover the measuring range of different sizes to meet diversified inspection needs.

Measurement accuracy: With micron-level measurement accuracy, it can meet the high-precision inspection requirements of PCB circuit boards.

Software system: Built-in powerful measurement software, supporting automatic measurement, data recording, statistical analysis and other functions to improve inspection efficiency.

Operation Steps

Sample Preparation: Fix the PCB to be tested on the working table of the measuring instrument to ensure that its position is stable and easy to measure.

Equipment calibration: turn on the measuring instrument, system calibration, including the calibration of the optical system and the calibration of the sensor to ensure the accuracy of the measurement.

Measurement Setting: According to the characteristics and inspection requirements of the circuit board, select the appropriate measurement mode and parameter settings, such as illumination intensity and magnification.

Image Acquisition: Through the operation and control interface, start the image acquisition function to obtain a clear image of the circuit board.

Data Measurement and Analysis: Use the tool function of the measurement software to perform size measurement, shape analysis and other operations on the captured image. The software will automatically calculate and record the measurement data, and at the same time provide statistical analysis results of the data to facilitate the user's evaluation of the measurement results and decision-making.

Report Generation: After the measurement is completed, the measurement software can generate a detailed measurement report, which includes measurement data, analysis results, image screenshots, etc. Users can export the report to different formats according to their needs, so as to facilitate archiving, sharing and further discussion.

Application Areas

Electronics manufacturing industry: used to inspect PCB circuit boards of various electronic products to ensure that their dimensional accuracy and quality meet the standards.

Semiconductor industry: high-precision measurement of semiconductor devices in the process of chip manufacturing and packaging.

Automotive electronics industry: testing the circuit board of automotive electronic components to ensure their reliability and safety.

Aerospace industry: to meet the needs of aerospace electronic products for high-precision and high-reliability testing.

V. Advantageous features

High-precision measurement: using advanced optical imaging technology and high-resolution sensors to achieve micron-level measurement accuracy, ensuring the accuracy of the test results.

Non-contact measurement: avoids the damage that traditional contact measurement may cause to the circuit board, and at the same time improves the measurement efficiency.

Automated operation: Equipped with automatic focusing, automatic measurement, automatic data recording, etc., which reduces human error and improves inspection efficiency.

Powerful software functions: the measurement software provides rich measurement tools and analysis functions, supports CAD data comparison, and facilitates users to carry out complex measurements and quality control.

Wide applicability: able to adapt to different sizes and shapes of PCB circuit board inspection, to meet the inspection needs of a variety of industries.

Image measuring instrument plays an irreplaceable role in PCB circuit board inspection. It can not only quickly and accurately measure the parameters of the circuit board, but also help manufacturers to find potential problems in the production process, improve product quality and production efficiency. Choose a high-performance image measuring instrument, is for your business to build a strong quality defense, enhance market competitiveness.

Send Inquiry to This Supplier

You May Also Like

-

High Precision Brinell Hardness Tester Machine for Steel Alloy - Free ShippingUS$ 2000 - 3000MOQ: 1 Set

-

Auto-Rotary Vickers Hardness Tester With 0.1μm Resolution & Data ExportUS$ 2000 - 3000MOQ: 1 Set

-

Lab-Use Micro Hardness Tester With 50X Lens & 99 Groups Data StorageUS$ 2000 - 3000MOQ: 1 Set

-

Multi-Function Hardness Testing Machine for Metal Sheets/Bars/TubesUS$ 2000 - 3000MOQ: 1 Set

-

Multi-Function Hardness Testing Machine for Metal Sheets/Bars/TubesUS$ 2000 - 3000MOQ: 1 Set

-

Compact Tabletop Rockwell Hardness Tester for Small Parts - 0.5% Measurement AccuracyUS$ 2000 - 3000MOQ: 1 Set

-

Automatic Brinell Hardness Tester Machine With 250kgf Test Force CapacityUS$ 2000 - 3000MOQ: 1 Set

-

High-Speed Vickers Screen Digital Hardness Tester for Ceramic Materials - 0.1μm PrecisionUS$ 2000 - 3000MOQ: 1 Set

-

3-in-1 Rockwell/Brinell/Vickers Hardness Tester for Metallurgical LabsUS$ 2000 - 3000MOQ: 1 Set

-

Automatic Turret Hardness Tester Machine With 5X Objective LensUS$ 2000 - 3000MOQ: 1 Set