- Guangdong Derui testing equipment Co., Ltd

-

Dongguan, Guangdong, China

- Main products: Aging Test Chamber, Temperature and Humidity Test Chamber, High and Low Temperature Circulatory Test Chamber, Rapid Temperature Change Test Chamber, Saline Water Spray Tester, Packaging and transportation Tester, Vibration Tester, Tensile Tester, Furniture tester

Home > Products > UNIVERSAL TEST EQUIPMENT > CE ISO 17025 Certified Image Measuring Instrument for Precision Metrology

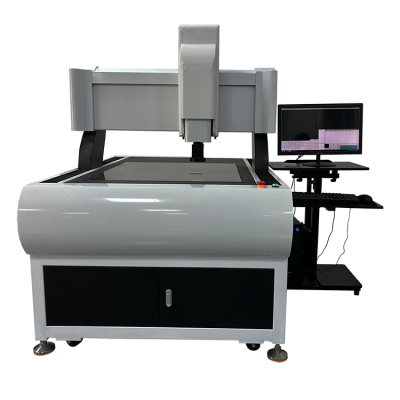

CE ISO 17025 Certified Image Measuring Instrument for Precision Metrology

- 100 Set / Sets per Month

- shenzhen

- T/T L/C D/P Other

- 7 days

You May Like

-

Image Measuring Instrument for PCB Circuit Board Inspection

-

Image Measuring Instrument for Automotive Component Dimensional Control

-

Image Measuring Instrument for Aerospace Composite Material Analysis

-

Image Measuring Instrument for Aerospace Composite Material Analysis

-

Image Measuring Instrument for Aerospace Composite Material Analysis

-

Image Measuring Instrument for Glass & Optics Surface Defect Detection

Product Details

| Brand Name | Deruitest | Place of Origin | China | |

| Model Number | DR-G301 | Power | Other, 220V | |

| Usage | Other |

Product Description

Technical parameter:

Model | DR-G301 | DR-G301-1 | DR-G301-2 | |

Table | Metal table size(mm) | 340 × 152 | 350×170 | 450 × 280 |

Glass table size(mm) | 196 × 96 | 246× 120 | 306× 196 | |

X coordinate travel (mm) | 150 | 200 | 250 | |

Y coordinate travel (mm) | 50 | 100 | 150 | |

Z coordinate travel (mm) | 90(Focusing) | 100( Focusing ) | 100( Focusing ) | |

Measuring accuracy (μm) | 3+L/50 | 3+L/75 | 3+L/75 | |

X, Y Block, Digital Resolution | 0.001mm | |||

Projection screen | Size (mm) | Ø312, Terms of Use>Ø300( Engraved with the word line m ) | ||

Rotation range | 0~360° | |||

Rotation Digital Resolution | 1' or 0.01° | |||

Mirror Matter | Magnification | 10X( Necessary ) 20X(Option) 50X ( Option ) 100X ( Option ) | ||

Line field of view in object (mm) | Ø30 Ø15 Ø6 Ø3 | |||

Work in object distance (mm) | 77.7 44.3 24.5 25.3 | |||

Data Processor | DC-3000 multi-function data processing system, all the Chinese showed they can do more sampling, coordinate rotation, point, line, distance, angle measurement | |||

Instrument lighting | Transmission and reflection of light source are: 24V, 150W halogen lamp | |||

Instrument Power | 110V/ 220V(AC), 50/60HZ, Total power 400W | |||

Cooling method | Forced air-cooled (3 axial fans) | |||

Dimensions | L × W × H (mm) | 792× 544 × 975 | 770 × 550× 1120 | 770 ×550× 1120 |

Weight | Unit Kg | 150 | 150 | 150 |

Options | Micro-printer, optical Edge Detector, M2D software; detailed description see Annex projector. | |||

CE ISO 17025 Certified Image Measuring Instruments: Excellence in Precision Measurement

In the field of modern industrial production and quality control, accurate measurement technology is a key factor in ensuring product quality and performance. CE ISO 17025 certified image measuring instrument, as a representative device for precision measurement, combines advanced optical imaging technology and high-precision measurement system to provide reliable dimensional measurement solutions for various industries. In this article, we will discuss the characteristics, advantages, application areas and usage of this measuring instrument to help you fully understand this precision measurement tool.

I. Product Overview

CE ISO 17025 certified image measuring instrument is a high-precision measuring device that integrates optical imaging, image processing and precision measurement. It accurately projects the image of the measured object onto the sensor through the advanced optical system and high-resolution imaging technology, and then analyzes and processes the image with professional measuring software, thus realizing the precise measurement of the object's size, shape, position and other parameters. The measuring instrument complies with the ISO/IEC 17025:2017 standard jointly formulated by the International Organization for Standardization and the Institute of Electrical and Electronic Engineers, which signifies that it has reached the international advanced level in terms of measurement capability, data processing and quality control, and is able to provide users with accurate, reliable and traceable measurement results.

Technical Parameters

Optical system: Equipped with high-precision optical lens and lighting system to ensure clear and accurate imaging.

Sensor: High-resolution CCD or CMOS sensor is adopted to capture high-quality images.

Measuring range: Depending on the model, the measuring range can cover different sizes to meet diversified measurement needs.

Measurement Accuracy: Extremely high measurement accuracy, up to the micron level, suitable for measurement tasks with stringent accuracy requirements.

Software system: Built-in powerful measurement software, supporting automatic measurement, data recording, statistical analysis and other functions, to improve the measurement efficiency and convenience of data management.

Operation Steps

Sample preparation: Fix the sample to be measured on the working table of the measuring instrument to ensure that its position is stable and easy to measure.

Equipment calibration: Turn on the measuring instrument and carry out system calibration, including the calibration of the optical system and the calibration of the sensor to ensure the accuracy of the measurement.

Measurement Setting: According to the characteristics of the sample and the measurement requirements, select the appropriate measurement mode and parameter settings, such as illumination intensity, magnification, and so on.

Image Acquisition: Through the operation control interface, start the image acquisition function to obtain a clear image of the sample.

Data Measurement and Analysis: Use the tool function of the measurement software to perform size measurement, shape analysis and other operations on the acquired image. The software will automatically calculate and record the measurement data, and at the same time provide the statistical analysis results of the data, which is convenient for the user to evaluate and make decisions on the measurement results.

Report Generation: After the measurement is completed, the measurement software can generate a detailed measurement report, which includes measurement data, analysis results, image screenshots, etc. Users can export the report to different formats according to their needs, so as to facilitate archiving, sharing and further discussion.

Application Areas

Mechanical manufacturing industry: used to measure the size, shape and positional tolerance of various mechanical parts to ensure that the processing accuracy of the parts meets the design requirements.

Electronic and electrical appliances industry: in the production process of electronic components, circuit boards, etc., the size and spacing of tiny parts are measured accurately to ensure product quality and performance stability.

Automobile manufacturing industry: Measure the size and shape of automobile parts to ensure the assembly accuracy and overall performance of the parts, and improve the safety and reliability of the car.

Aerospace field: to meet the demand for high precision measurement of aerospace parts, to ensure that the manufacturing accuracy and quality control of aircraft parts meet strict standards.

Precision mold manufacturing: help mold manufacturers accurately measure the size and shape of molds, ensure the manufacturing accuracy and service life of molds, and improve the molding quality of products.

V. Advantageous Features

High-precision Measurement: With advanced optical imaging technology and high-resolution sensors, it is capable of achieving micron-level measurement accuracy, providing reliable data support for precision manufacturing and quality control.

Efficient data processing: the built-in measurement software has powerful data processing capabilities, can quickly and automatically complete the measurement task and generate detailed measurement reports, greatly improving the measurement efficiency and convenience of the workflow.

Wide range of application adaptability: Suitable for a wide range of sample types, whether metal, plastic or composite materials, etc., can be easily coped with, to meet the measurement needs of different industries and application scenarios.

Compliance with international standards: CE and ISO 17025 certifications ensure that the equipment complies with international standards in terms of measurement capability, data processing and quality control, providing users with accurate, reliable and traceable measurement results, which helps to enhance the competitiveness of users' products in the market and quality reputation.

Good Repeatability and Stability: The use of high-quality optical components and stable mechanical structure design ensures the repeatability and stability of the measurement results, even in a long period of continuous measurement, it can also maintain a high degree of accuracy in the measurement performance, which provides a stable measurement basis for the quality control and optimization of the production process.

VI. Summary

Contact Us

- Guangdong Derui testing equipment Co., Ltd

- Contact nameLI Chat Now

- AddressRoom 113, 1st Floor, No. 3, Shugang Avenue, Hongmei Town, Dongguan, Guangdong

Product Categories

| ENVIRONMENTAL TEST CHAMBER | UNIVERSAL TEST EQUIPMENT | FURNITURE TEST EQUIPMENT | PAPER PACKAGING TEST EQUIPMENT |

| Test equipment for cartons and packages |

New Products

-

Digital Hardness Tester for Metal/Rockwell/HRC with LCD Screen & CE Certificate

-

High Precision Brinell Hardness Tester Machine for Steel Alloy - Free Shipping

-

Auto-Rotary Vickers Hardness Tester with 0.1μm Resolution & Data Export

-

Lab-Use Micro Hardness Tester with 50X Lens & 99 Groups Data Storage

-

Multi-Function Hardness Testing Machine for Metal Sheets/Bars/Tubes

-

Multi-Function Hardness Testing Machine for Metal Sheets/Bars/Tubes

-

Compact Tabletop Rockwell Hardness Tester for Small Parts - 0.5% Measurement Accuracy

-

Automatic Brinell Hardness Tester Machine with 250kgf Test Force Capacity

-

High-Speed Vickers Screen Digital Hardness Tester for Ceramic Materials - 0.1μm Precision

-

3-in-1 Rockwell/Brinell/Vickers Hardness Tester for Metallurgical Labs

-

Automatic Turret Hardness Tester Machine with 5X Objective Lens

-

Multi-Standard Hardness Tester Support ASTM E18/ISO 6508/JIS B7725

-

Automatic Brinell Hardness Tester with Ball Indentor & Microscope

-

Dual Scale Rockwell Hardness Tester (HRC & HRB) - Plug & Play Design

-

Bulk Order Discount - Professional Hardness Testers for Global Suppliers

-

Digital Martindale Abrasion Tester for Textile/Leather - ASTM D4966 & ISO 12947

-

Industrial Martindale Tester for Automotive Seat Fabric - 9kPa Load & Data Export

-

Textile Factory Martindale Tester with 12 RPM Speed & 1000h Durability

-

OEM Service Customized Martindale Abrasion Machine with Brand Logo Printing

-

High-Speed Martindale Tester for Shoes/Synthetic Leather - 25mm Stroke

-

Touchscreen Martindale Abrasion Tester for Quality Control Labs - Plug & Play

-

Bulk Order Discount - Martindale Testers for Textile Suppliers (MOQ 5 Sets)

-

Dual-Mode Martindale Tester (Circular/Linear Motion) for R&D Centers

-

All-in-One Martindale Kit: Tester + Abrasive Paper + Sample Cutter + Tools

Popular Searches

- digital tester

- Resistance Tester

- electrical instrument

- test instrument

- lab equipment

- analysis instrument

- laboratory instrument

- Asphalt Mixture Mixer

- launch x431 master

- x431

- Gloss Meter

- Resistance Meter

- digital instrument

- dc load bank

- testing equipment

- testing machine

- battery load bank

- Circuit Tester

- Impact Tester

- lab instrument

- weather station

- gps receiver

- laboratory instruments

- test equipment

- laboratory equipment

- electronic timer

- electronic meter

- electronic instrument

- Electricity Meter

- data collector

Recommended Products

- WTB-CUP series computerized cupping testing machine

- GRP Gre Pipe Cyclic Hydraulic Test Systems

- GRP Pipe Ring Stiffness Testing Machines

- Glass Reinforced Polyester Split Disc Testing Machine

- GRP Pipe Gre Pipe Hdb Pdb Long-Terms Testing System

- continuous pellet compression testing static pellet compression test dynamic pellet compression test

- pellet fracture load testing pellet load vs deformation curve bulk density and strength test for pellets

- high-accuracy pellet compression machine supplier pellet crushing strength measurement pellet breaking force test

- pellet strength testing equipment price quote customized pellet compression testing solutions export pellet testing machines worldwide

- lab pellet strength testing machine for sale how to test pellet compressive strength pellet compression tester for laboratory

- standardized pellet mechanical strength test pellet compression tester supplier and manufacturer

- EN ISO 4700 iron ore pellet strength test ASTM pellet crush strength testing machine ISO standard pellet compression tester

Find Similar Products By Category

- Instruments & Meters > Test Instrument > Test Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

LI

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

LI

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile