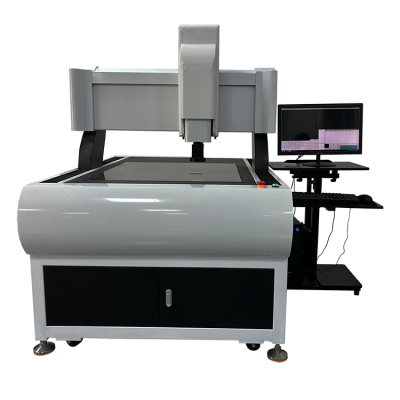

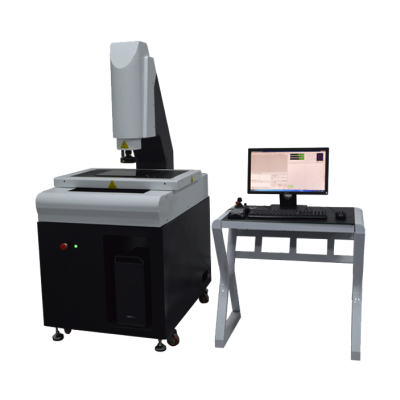

Image Measuring Instrument for Aerospace Composite Material Analysis

Technical parameter:

Model | DR-G301 | DR-G301-1 | DR-G301-2 | |

Table | Metal table size(mm) | 340 × 152 | 350×170 | 450 × 280 |

Glass table size(mm) | 196 × 96 | 246× 120 | 306× 196 | |

X coordinate travel (mm) | 150 | 200 | 250 | |

Y coordinate travel (mm) | 50 | 100 | 150 | |

Z coordinate travel (mm) | 90(Focusing) | 100( Focusing ) | 100( Focusing ) | |

Measuring accuracy (μm) | 3+L/50 | 3+L/75 | 3+L/75 | |

X, Y Block, Digital Resolution | 0.001mm | |||

Projection screen | Size (mm) | Ø312, Terms of Use>Ø300( Engraved with the word line m ) | ||

Rotation range | 0~360° | |||

Rotation Digital Resolution | 1' or 0.01° | |||

Mirror Matter | Magnification | 10X( Necessary ) 20X(Option) 50X ( Option ) 100X ( Option ) | ||

Line field of view in object (mm) | Ø30 Ø15 Ø6 Ø3 | |||

Work in object distance (mm) | 77.7 44.3 24.5 25.3 | |||

Data Processor | DC-3000 multi-function data processing system, all the Chinese showed they can do more sampling, coordinate rotation, point, line, distance, angle measurement | |||

Instrument lighting | Transmission and reflection of light source are: 24V, 150W halogen lamp | |||

Instrument Power | 110V/ 220V(AC), 50/60HZ, Total power 400W | |||

Cooling method | Forced air-cooled (3 axial fans) | |||

Dimensions | L × W × H (mm) | 792× 544 × 975 | 770 × 550× 1120 | 770 ×550× 1120 |

Weight | Unit Kg | 150 | 150 | 150 |

Options | Micro-printer, optical Edge Detector, M2D software; detailed description see Annex projector. | |||

Product Overview Related

Accurate Measurement: Emphasize that the instrument can realize high-precision image measurement in aerospace composite material analysis, for example, the measurement accuracy can reach how many microns level, highlighting its accuracy for composite material microstructure and size measurement.

Advanced technology: Mention the advanced imaging technology and image processing algorithms adopted by the product, such as the adoption of high-resolution digital imaging technology, artificial intelligence-based image recognition and analysis algorithms, etc., reflecting the scientific and technological content and advantages of the product.

Professional design: It is stated that the instrument is specially tailored and designed for the field of aerospace composite material analysis. Considering the special characteristics of aerospace materials (e.g. high strength, light weight, complex structure, etc.), professional optimization and design have been carried out in the function, structure and operation of the instrument.

Functional features related

Multi-dimensional measurement: elaborates that the instrument is able to analyze and measure composite materials from multiple dimensions, for example, it can not only measure the surface morphology and dimensional specifications of the material, but also detect the internal defects, porosity and other microstructural features to provide comprehensive material information.

Non-Contact Measurement: Emphasizes its non-contact measurement, which is very important for aerospace composites, a material that requires high surface integrity and accuracy, avoiding the damage and errors that may be caused by traditional contact measurement.

Fast and efficient: Highlighting the instrument's fast and efficient measurement, it is able to complete the measurement and analysis of a large number of samples in a short period of time to meet the aerospace industry's high efficiency needs for material testing, such as the number of samples that can be measured per hour.

Data processing and analysis function: Introducing the powerful data processing and analysis software equipped with the instrument, which can process, analyze and store the collected image data in real time, generate detailed reports and visualization charts, helping researchers and engineers to quickly and accurately obtain the key information of the material, and carry out quality control and performance evaluation.

Application Scenario Related

Aerospace Parts Inspection: Describe in detail the application of the instrument in the manufacturing process of aerospace parts, such as the material quality inspection of aircraft wings, engine blades and other key parts, to ensure that the parts meet the strict design and safety standards.

Material R&D and Improvement: explains how the instrument helps the R&D of aerospace composite materials, through the measurement and analysis of composite materials prepared by different formulas and processes, it provides data support and technical basis for the optimization and improvement of material performance.

Quality Monitoring and Guarantee: Emphasize the quality monitoring role of the instrument in the production process of aerospace materials, which can monitor the quality status of materials in real time, discover and solve potential quality problems in time, and guarantee the quality and safety of aerospace products.

Product Advantages and Values

Reliability and Stability: Elaborate the reliability and stability of the product under complex environmental conditions, such as being able to work normally in harsh environments such as high temperature, high humidity, strong radiation, etc., to ensure the accuracy and consistency of the measurement results, and to reduce the production delays and quality risks caused by equipment failure.

Enhancement of work efficiency and quality: summarize the practical benefits that the use of the instrument can bring to aerospace enterprises, such as improving production efficiency, reducing production costs, enhancing product quality and market competitiveness, etc., highlighting the investment value of the product.

Comply with industry standards and norms: Mention that the product complies with the relevant standards and norms of the international and domestic aerospace industry, such as ISO, ASTM and other standards, to ensure the authority and recognition of the measurement results, and provide enterprises with a reliable means of testing.

Customer cases and reputation related

Successful application cases: Cite some successful cases of domestic and foreign well-known aerospace enterprises or scientific research institutions using the instrument, detailing the results and benefits they have achieved in the process of using it, increasing the credibility and persuasiveness of the product.

Customer Evaluation and Feedback: Cite the customer's favorable comments and feedback on the product, such as the customer's recognition and praise of the instrument's measurement accuracy, ease of operation, after-sales service, etc., so that potential customers can better understand the actual use of the product and its value.

Technical support and service related。

Send Inquiry to This Supplier

You May Also Like

-

Lab-Use Micro Hardness Tester With 50X Lens & 99 Groups Data StorageUS$ 2000 - 3000MOQ: 1 Set

-

Multi-Function Hardness Testing Machine for Metal Sheets/Bars/TubesUS$ 2000 - 3000MOQ: 1 Set

-

Multi-Function Hardness Testing Machine for Metal Sheets/Bars/TubesUS$ 2000 - 3000MOQ: 1 Set

-

Compact Tabletop Rockwell Hardness Tester for Small Parts - 0.5% Measurement AccuracyUS$ 2000 - 3000MOQ: 1 Set

-

Automatic Brinell Hardness Tester Machine With 250kgf Test Force CapacityUS$ 2000 - 3000MOQ: 1 Set

-

High-Speed Vickers Screen Digital Hardness Tester for Ceramic Materials - 0.1μm PrecisionUS$ 2000 - 3000MOQ: 1 Set

-

3-in-1 Rockwell/Brinell/Vickers Hardness Tester for Metallurgical LabsUS$ 2000 - 3000MOQ: 1 Set

-

Automatic Turret Hardness Tester Machine With 5X Objective LensUS$ 2000 - 3000MOQ: 1 Set

-

Multi-Standard Hardness Tester Support ASTM E18/ISO 6508/JIS B7725US$ 2000 - 3000MOQ: 1 Set

-

Automatic Brinell Hardness Tester With Ball Indentor & MicroscopeUS$ 2000 - 3000MOQ: 1 Set