Wedge Wire Screen Tube Has Strong Corrosion Resistance, SS Johnson Wire Wrapped Screen

Product Spotlights

Wedge Wire Screen Tube has Strong Corrosion Resistance, SS Johnson Wire Wrapped Screen

Products name:Well screen(water filter)

Contact Person: Star Lee 86-0-13315867171

MSN: feiyatrade@hotmail.com

E-mail: starlee@feiyaguoji.com

The continuous-slot well screen is widely used throughout the world for water, oil, and gas wells, and is the dominant screen type used in the water well industry.

Continuous-Slot Well Screen is made by winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights. Slot opening for continuous-slot screens are manufactured by spacing successive turns of the outer wire to produce the desired slot size.

All slots should be clean and free of burrs and cuttings.

Each slot opening between adjacent wires is V-shaped, from the special shape of wire used to form the screen surface. The V-shaped openings designed to be nonclogging, are narrowest at the outer face and widen inwardly; they allow

1. Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2. Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

3. Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

4. Low operational costs: Large open area with an effective flow, high yield and a low pressure drop (dP)

5. Long live: Welded at each intersection creating a strong and durable screen.

6. Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components.

7. Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures. Each slot opening between adjacent wires is V-shaped, resulting from the special shape of the wire used to form the screen surface. The V-shaped opeings, designed to be nonclogging, are narrowest at the outer face and widen inwardly. Continuous-slot screens provide more intake area per unit area of screen surface than any other type. For any given slot size, this type of screen has maximum open area.

.Open area up to 60%.

Material : Low Carbon ,Low Carbon Galvanized steel (LCG),,steel treated with plastic spraying,Stainless Steel( 304,etc.)

Lengths up to 6 meters.

Diameter ranging from 25 mm to800 mm

End Connection :Plain beveled ends for butt welding or threaded.

-

SS 205 / 304 / 316 / 316L Johnson Screen Pipe , Johnson Wire Wrap Screen Tube

-

Product Description:

Stainless Steel 205 / 304 / 316 / 316L Johnson Wire Wrap Screen Tube is made by winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights.The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights.There is a fixed value slot between each v wire, and the continuous slot, designed to provide maximum open are to reduce entrance velocity, increase hydraulic efficiency and promote more effective development.

-

Specification:

-

Material Stainless steel Grade 205, 304,304L, 316L O.D 89mm 117mm 219mm 273mm 325mm Size 3-1/2" 4-1/2" 8-5/8 " 10-3/4" 12" Slot size 0.5 mm,0.63mm, 0.75mm, 1.0mm Length 2.9m / 5.8 m, 100-6000mm End connection Welded rings Wire size 63# 93# 118 # Support rod 140 # Wire shape V shape -

Regular Specifications:

-

SIZE

(INCH)

O.D

(MM)

SLOT

(MM)

LENGTH

(M)

COLLAPSE

STRENGTH

(BAR)

TENSILE

WEIGHT

(TON)

WRAP WIRE(WIDTH*HEIGHT)

(MM)

RODS

(MM)

3-1/2 88.9 1.0 3 >22 10.2 2.3*3.5 3.8MM/22 4-1/2 114.3 1.0 3 >28 11.5 2.3*3.5 3.8MM/22 6-5/8 168.3 0.75 5.8 >40 12.8 2.3*3.5 3.8MM/32 6-5/8 168.3 1.0 5.8 >33 12.8 2.3*3.5 3.8MM/32 6-5/8 168.3 0.63 5.8 >83 45 3.2*6.0 6.0MM*32 8-5/8 219.1 1.0 5.8 >34 21.9 2.3*3.5 3.8MM/48 8-5/8 219.1 1.0 5.8 >50 38.2 3.0*5.0 4.0MM/48 8-5/8 219.1 1.0 5.8 >60 46 3.2*6.0 5.0MM/48 10-3/4 273.1 0.75 5.8 >50 32.9 2.3*3.5 4.9MM/55 10-3/4 273.1 1.0 5.8 >60 39.5 3.0*5.0 4.9MM/55 10-3/4 273.1 1.0 5.8 >100 48 3.2*6.0 5.0MM/55 12-3/4 323.9 1.0 5.8 >120 37.2 3.0*5.0 4.0MM/50 14 355.6 1.0 3 >80 37.8 3.0*5.0 4.0MM/59 -

Characteristic:

Not easy to jam

the special V shaped wire, make the hole of screen outside face is smaller than inside, so the hole is not easy to jam.

Slot even

The CNC machine tools strictly control the gap between the wire, so that the gap is even.

Strong corrosion resistance

Stainless steel 304 have the high corrosion resistance

-

Application:

Wre wrap screen pipe specific continuous-slot construction aims to optimize flow rates, minimize clogging and help develop the water-bearing geological formations faster. It is best applied in the following situations:

Geological formations comprised of small, fine particles

Water wells where gravel packs will be installed

Thin aquifers, where maximum open area is required

Large- and small-diameter deep wells

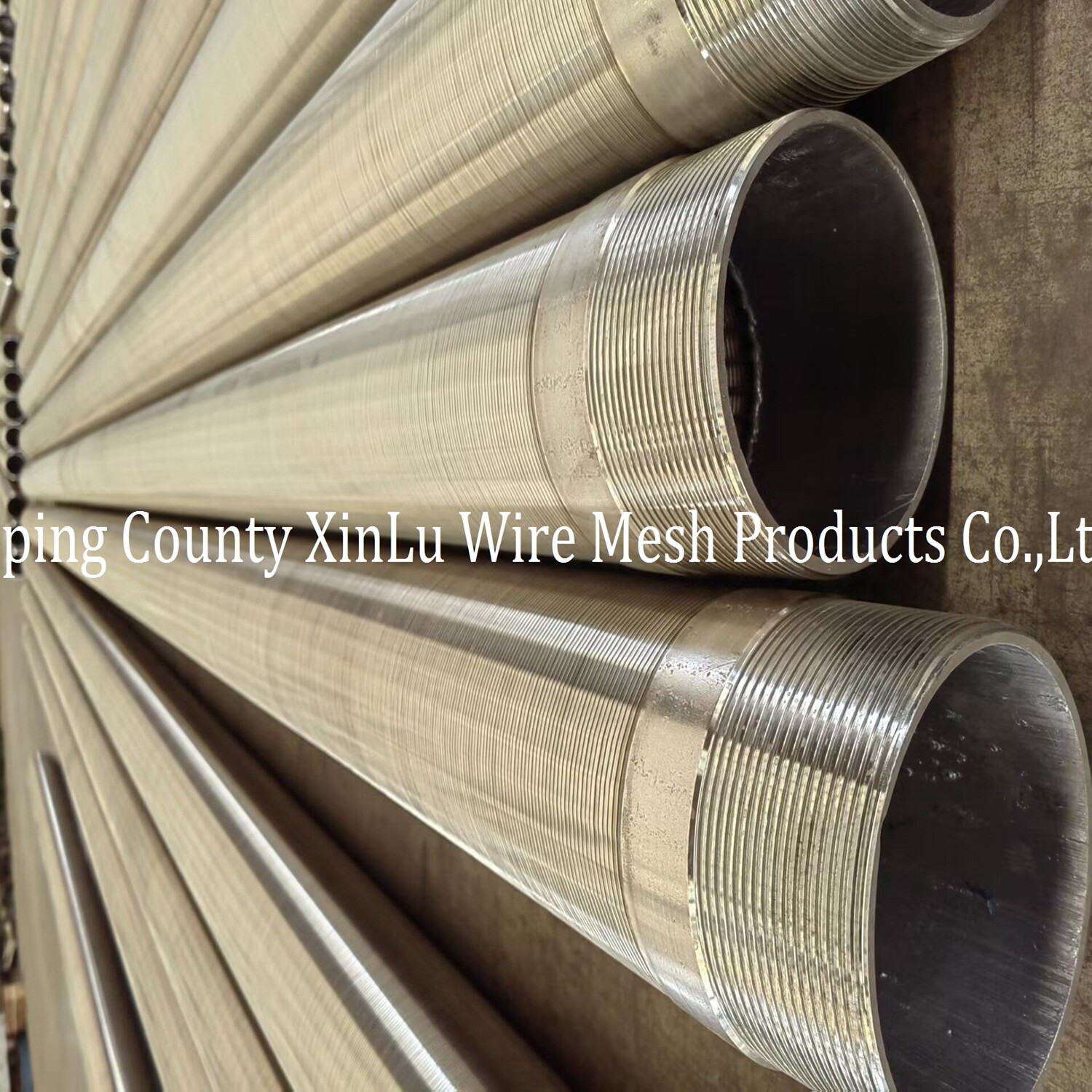

Pictures:

Send Inquiry to This Supplier

You May Also Like

-

Water & Gas Strainer Nozzle – SS Johnson Screen Filter for Dual-Phase ApplicationsUS$ 5 - 20MOQ: 100 Pieces

-

Johnson Wire Screen – Continuous Slot Water Well Screen for Heat Pump SystemsUS$ 50 - 100MOQ: 30 Pieces

-

Wire-Wrapped Continuous Slot Screen – Precision Sand Control for Water WellsUS$ 30 - 160MOQ: 30 Pieces

-

Water Well Screen for Dewatering Deep DrillingUS$ 30 - 150MOQ: 30 Pieces

-

Water Well Screen, Wedge Wire ScreenUS$ 10 - 100MOQ: 30 Meters

-

2-7/8\" Wire-Wrapped Continuous Slot Johnson Well Screen for Sand ControlUS$ 30 - 300MOQ: 30 Pieces

-

Low Carbon Galvanized Wedge Wire Water FilterUS$ 10 - 100MOQ: 30 Meters

-

Grovel Pack Screens / Johnson Type Wedge Wire Water Well ScreenUS$ 29.9 - 299.9MOQ: 30 Pieces

-

Stainless Steel Water Well Wedge Wire Screen/ Wedge Wire Screen for Well DrillingUS$ 9.9 - 49.99MOQ: 30 Meters

-

Stainless Steel No Magnetic Wedge Wire Water Well ScreenUS$ 30 - 450MOQ: 30 Pieces