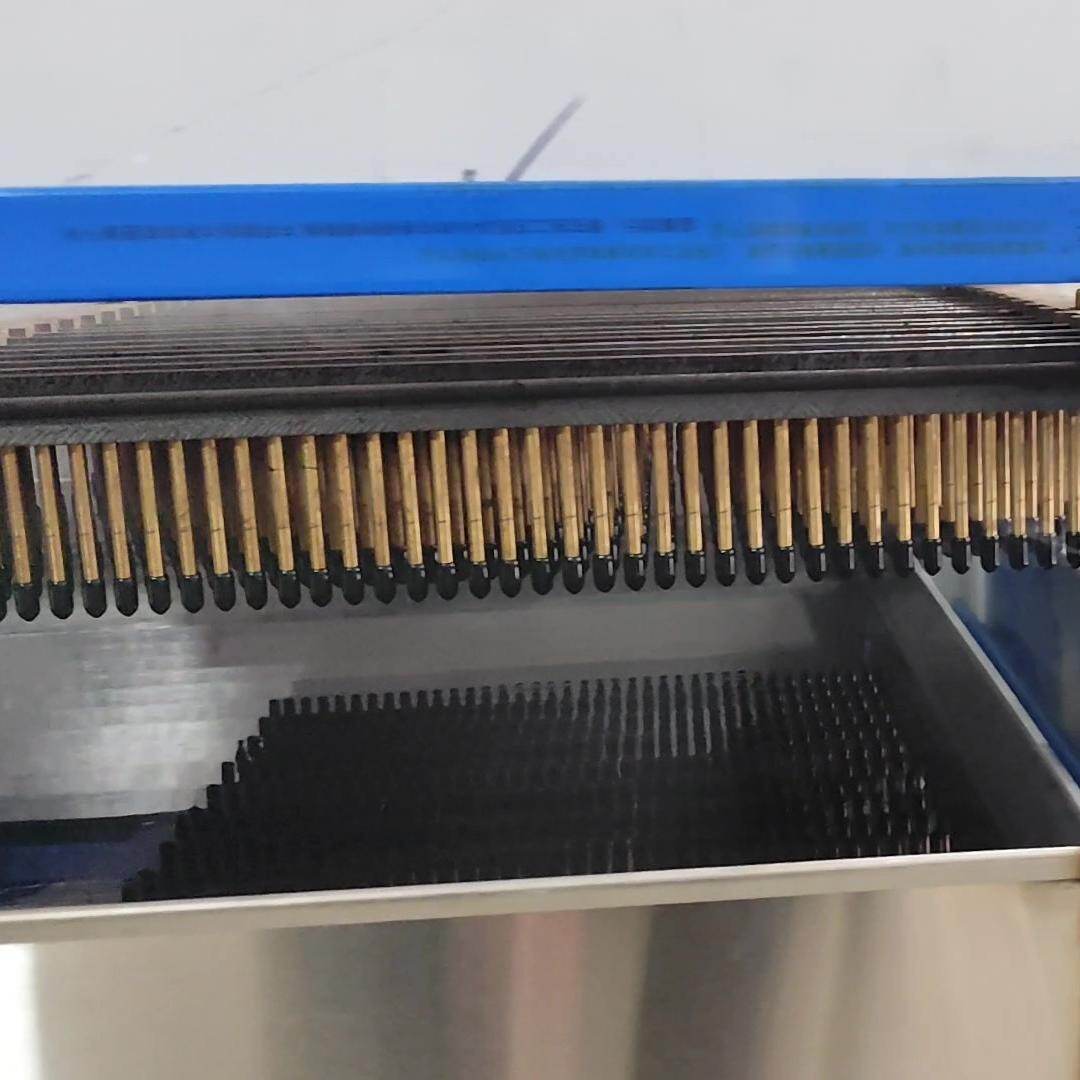

Industrial-Grade Dip Mould Machine for Metal and Plastic Components

As Nanjing Vaughn Tech Co.Ltd, a dedicated manufacturer established in 2018, we proudly introduce our industrial-grade dip mould machine, engineered for superior performance in coating metal and plastic components. With a robust factory spanning 5,000-10,000 square meters and an annual export value of US$2.5 Million to US$5 Million, we leverage our expertise to deliver machines that enhance production efficiency and reduce operational costs. Our commitment to quality, backed by a team of 11-50 skilled professionals, ensures that this machine provides reliable, high-precision solutions for diverse industrial applications, helping you achieve consistent results and long-term savings.

This dip mould machine excels in handling both metal and plastic components, offering advanced features that streamline your coating processes. Key advantages include:

- High Precision Control: Equipped with automated systems for uniform coating thickness, minimizing waste and ensuring consistent quality across batches.

- Durability and Reliability: Built with stainless steel materials, it withstands harsh industrial environments, reducing downtime and maintenance needs.

- Energy Efficiency: Optimized power consumption lowers operational costs, with customizable power supply options to suit your facility's requirements.

- Versatile Applications: Ideal for automotive, electronics, consumer goods, and more, supporting various component sizes and shapes through adaptable configurations.

Technical specifications highlight the machine's adaptability and performance. Below is a summary of common parameters; note that all values are customizable based on client needs:

| Parameter | Standard Range | Customization Options |

| Max Load Capacity | 50-200 kg | Adjustable upon request |

| Coating Speed | 1-5 meters/min | Variable settings |

| Power Consumption | 3-10 kW | Compatible with 220V/380V |

| Dimensions (LxWxH) | 2m x 1.5m x 1.8m | Scalable for space constraints |

Clients benefit from reduced labor costs due to semi-automatic or fully automatic operation, improved product longevity through even coating, and faster turnaround times. The machine's modular design allows for easy integration into existing production lines, enhancing overall workflow without major overhauls. Additionally, its compliance with industry standards ensures safety and environmental responsibility, contributing to sustainable manufacturing practices.

Backed by Nanjing Vaughn Tech's extensive certifications including ISO9001, ISO14000, and OHSAS18001, this machine meets global quality benchmarks, giving you confidence in every investment. We serve major markets across North America, South America, Europe, Asia, Africa, and Oceania, with efficient shipment from ports like Shanghai, Ningbo, Tianjin, and Qingdao. Our proven track record in exports and domestic sales underscores our reliability—partner with us to elevate your production capabilities. Contact us today for a personalized consultation or to request a sample demonstration, and discover how our dip mould machine can drive your business forward.

Frequently Asked Questions (FAQ)

-

Q: What industries commonly use this dip mould machine?

A: It is widely applied in automotive for part coating, electronics for insulation, and consumer goods manufacturing, among others, due to its versatility with metal and plastic components. -

Q: Can the machine handle different sizes of components?

A: Absolutely, the capacity is customizable, allowing adjustments for small to large parts, ensuring flexibility in your production process. -

Q: What certifications ensure the machine's quality and safety?

A: Our products adhere to certifications like ISO9001 for quality management and OHSAS18001 for occupational health, as listed in our compliance records. -

Q: How does the machine improve coating efficiency?

A: Through automated controls, it achieves uniform thickness with minimal material waste, reducing costs and enhancing product consistency compared to manual methods. -

Q: What is the typical lead time for delivery?

A: Standard models ship in 4-6 weeks, but this can vary based on customization; we provide estimates upon order confirmation. -

Q: Is training or support included with purchase?

A: Yes, operational training and technical support are available to ensure smooth integration and ongoing performance. -

Q: Can the machine be integrated into existing production lines?

A: Definitely, its modular design allows for easy adaptation, minimizing disruption and maximizing your current setup's efficiency. -

Q: Are samples available for testing?

A: Samples can be arranged upon request, allowing you to evaluate the machine's performance before full-scale implementation.

Send Inquiry to This Supplier

You May Also Like

-

High-Speed Dip Mould Machine for Ceramic and Glass CoatingNegotiableMOQ: 1 Set

-

PVC PE-Coated Zigzag Wiggle Wire Making Machine Line, Greenhouse Spring Wire Production EquipmentUS$ 2000 - 40000MOQ: 1 Set

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Dip Mould Machine For PVC Plastisol Caps Sleeves Cover RootsUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Dip PVC Plastisol Coating Equipment Line For Metal Handles RacksUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Fluidized Bed Dip Powder Coating Equipment LineUS$ 2000 - 40000MOQ: 1 Set

-

High Efficiency Automatic PVC Dip Mold Machine for Small Caps (200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Small Plastisol PVC Cap Molding Machine (Automatic, 200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Automatic PVC Dip Coating Machine for 8mm×14mm Small CapsUS$ 2000 - 40000MOQ: 1 Set

-

Greenhouse Wiggle Wire Making Machine, Pvc-coated Wiggle Wire MachineUS$ 2000 - 40000MOQ: 1 Set