As a dedicated manufacturer since 2018, Nanjing Vaughn Tech Co.Ltd brings you our cutting-edge Automatic Dip Mould Machine with PLC Control, designed for unparalleled precision in coating applications. With a factory spanning 5,000-10,000 square meters and annual exports valued at US$2.5 Million - US$5 Million, we leverage our expertise to deliver equipment that enhances efficiency and quality. Backed by certifications like ISO9001 and ISO14000, our machine ensures reliable performance for global markets, including North America, Europe, and Asia. This innovative solution is engineered to reduce waste and boost productivity, making it an essential asset for industries seeking consistent, high-quality coatings.

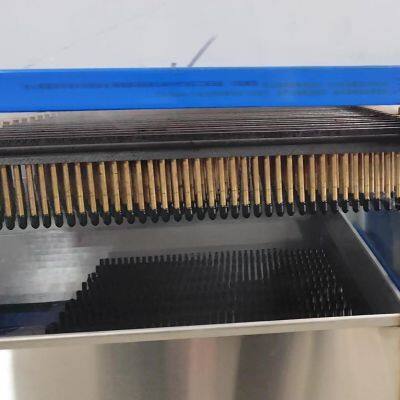

Key Features and Benefits: Our Automatic Dip Mould Machine combines advanced PLC control with fully automated operation to provide precise coating results. Here's a detailed breakdown of its capabilities:

- PLC Control System: Ensures accurate and repeatable coating processes, reducing human error and allowing for customizable programming to suit specific production needs.

- Automated Dipping Mechanism: Streamlines operations by handling immersion and withdrawal automatically, minimizing labor costs and increasing throughput for high-volume applications.

- Precision Coating Technology: Delivers uniform coating thickness with adjustable settings, ideal for sensitive materials like metals or plastics, ensuring defect-free finishes every time.

- Durable Construction: Built with robust materials to withstand industrial environments, offering long-term reliability and low maintenance requirements.

- Versatile Applications: Suitable for diverse industries such as automotive, electronics, and consumer goods, where consistent coating quality is critical.

Technical Specifications: Below is a summary of core parameters; note that all specifications are customizable to meet unique client demands.

| Parameter | Value |

| Maximum Coating Speed | Up to 12 meters per minute |

| Coating Thickness Range | 0.1mm to 5mm (adjustable) |

| Power Requirements | 220V/380V AC |

| Material Handling Capacity | Customizable based on dimensions |

| Control Interface | User-friendly PLC touchscreen |

Advantages for Your Business: Implementing this machine translates to tangible benefits, such as reduced operational costs through automation, improved product consistency for higher customer satisfaction, and scalability for future growth. Clients report up to 30% efficiency gains in coating processes, thanks to its precision engineering and easy integration into existing production lines.

With a proven track record of exporting to over 14 global markets, including North America, Eastern Europe, and Southeast Asia, and certifications like OHSAS18001 ensuring safety, Nanjing Vaughn Tech stands as a trusted partner for quality equipment. Our 11-50 skilled employees and ports like Shanghai and Ningbo facilitate swift deliveries. Invest in our Automatic Dip Mould Machine to elevate your coating operations—contact us today for a tailored consultation and quote to experience its reliability firsthand.

Frequently Asked Questions (FAQ):

-

Q: What materials can this machine coat?

A: It handles a wide range, including metals, plastics, and ceramics; specific compatibility is customizable upon request to suit your materials. -

Q: How precise is the coating thickness?

A: The PLC control allows adjustments from 0.1mm to 5mm, ensuring high accuracy for applications requiring fine tolerances. -

Q: Is training provided for operators?

A: Yes, comprehensive training is available to ensure smooth setup and operation, covering all aspects of the machine. -

Q: What certifications does the machine hold?

A: It meets ISO9001, ISO14000, and HACCP standards, guaranteeing quality and safety compliance. -

Q: Can it be integrated into automated production lines?

A: Absolutely; the machine is designed for seamless integration, with options for conveyor systems available upon request. -

Q: What is the typical lead time for delivery?

A: Lead times vary based on customization but are expedited through ports like Shanghai, with standard orders shipped within 4-6 weeks. -

Q: How energy-efficient is the machine?

A: It features optimized power consumption, reducing energy use while maintaining high output, for cost-effective operations. -

Q: Is warranty included?

A: A standard warranty covers parts and labor, with extended options customizable for added peace of mind.

Send Inquiry to This Supplier

You May Also Like

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Dip Mould Machine For PVC Plastisol Caps Sleeves Cover RootsUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Dip PVC Plastisol Coating Equipment Line For Metal Handles RacksUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Fluidized Bed Dip Powder Coating Equipment LineUS$ 2000 - 40000MOQ: 1 Set

-

High Efficiency Automatic PVC Dip Mold Machine for Small Caps (200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Small Plastisol PVC Cap Molding Machine (Automatic, 200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Automatic PVC Dip Coating Machine for 8mm×14mm Small CapsUS$ 2000 - 40000MOQ: 1 Set

-

Greenhouse Wiggle Wire Making Machine, Pvc-coated Wiggle Wire MachineUS$ 2000 - 40000MOQ: 1 Set

-

PVC Plastisol Production Equipment, Used to Produce Pvc Plastisol LiquidUS$ 2000 - 40000MOQ: 1 Set

-

Precision-Engineered PVC Plastisol Production Equipment Machine, Mixing TanksUS$ 2000 - 40000MOQ: 1 Set