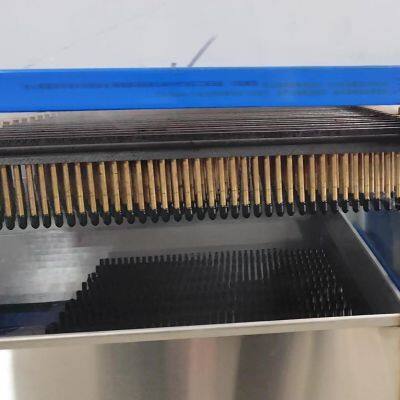

As an ISO-certified manufacturer established in 2018, Nanjing Vaughn Tech Co.Ltd brings precision engineering to polymer processing with our advanced Dip Mould Machine featuring integrated temperature control. Operating from our 5,000-10,000㎡ facility in Nanjing, we've designed this equipment to deliver consistent results for demanding industrial applications. The machine's core innovation lies in its precise thermal management system, enabling uniform polymer distribution and reducing material waste.

With annual exports valued at $2.5-5 million to global markets including North America, Europe and Southeast Asia, our solutions meet international quality benchmarks. The temperature-controlled dipping process ensures optimal viscosity control for various polymer compounds, significantly improving product finish quality while maintaining energy efficiency. Our technical team of 11-50 specialists has engineered this system for reliability in continuous production environments.

Technical Specifications & Features:

Precision temperature control with ±1°C accuracy

Programmable dipping cycles with adjustable immersion duration

Multi-zone heating for uniform thermal distribution

Stainless steel construction for chemical resistance

Modular design allowing capacity upgrades

Real-time temperature monitoring with digital display

Automated lifting mechanism with variable speed control

Energy-saving insulation system reducing heat loss

Performance Parameters:

| Parameter | Standard Specification | Customization Options |

| Heating Capacity | 5-10 kW | Scalable up to 30 kW |

| Dipping Depth | 500 mm | Up to 1500 mm |

| Cycle Time | 30-120 seconds | Programmable intervals |

| Temperature Uniformity | ±2°C across tank | Enhanced systems available |

The integrated PID controller maintains polymer viscosity within optimal processing range, critical for achieving consistent coating thickness. This eliminates common defects like dripping or uneven coverage. For operations handling multiple polymer types, the system's memory function stores up to 20 preset profiles for rapid material changeovers. Safety features include automatic overheat shutdown and emergency stop controls, while the accessible design simplifies maintenance procedures.

Operational Benefits:

Reduces polymer waste by up to 25% through precise temperature management

Decreases energy consumption with efficient insulation design

Enables processing of temperature-sensitive polymers without degradation

Minimizes production downtime with quick-change tooling options

Improves workplace safety with enclosed heating elements

Backed by our comprehensive quality management systems certified to ISO9001, ISO14000 and OHSAS18001 standards, this equipment meets rigorous manufacturing protocols. With established shipping routes through Shanghai, Ningbo, Tianjin and Qingdao ports, we efficiently serve clients across 15 global regions including North America, Western Europe and Southeast Asia. Our technical support team provides installation guidance and maintenance training, ensuring optimal performance throughout the machine's lifecycle.

Trusted by manufacturers worldwide, this temperature-controlled solution represents our commitment to innovation in polymer processing technology. Contact our engineering department to discuss custom configurations tailored to your specific production volumes and material requirements.

Frequently Asked Questions:

Q: What polymer types is this machine compatible with?

A: The system processes various thermoplastics including PVC, polyurethane, and latex compounds. Compatibility depends on melting points within the machine's operational range.

Q: How is temperature uniformity maintained in larger tanks?

A: Multi-zone heating with independent controllers ensures consistent thermal distribution across all tank dimensions, preventing cold spots.

Q: What safety certifications does the electrical system have?

A: Components meet international electrical standards with OHSAS18001 compliance for workplace safety.

Q: Can existing dipping equipment be retrofitted with your temperature system?

A: Retrofit kits are available for select models - provide your equipment specifications for compatibility assessment.

Q: What maintenance does the heating system require?

A: Annual calibration checks and element inspections are recommended, with easily accessible components for servicing.

Q: How quickly can temperature changes be achieved during production?

A: Typical ramp rates are 2-5°C/minute depending on tank volume and polymer thermal mass.

Q: Do you provide operational training with installation?

A: Comprehensive training on temperature profiling and maintenance procedures is included with all installations.

Q: What is the lead time for custom-configured machines?

A: Standard units ship in 4-6 weeks; custom configurations require 8-10 weeks based on complexity.

Send Inquiry to This Supplier

You May Also Like

-

Automatic Fluidized Bed Dip Powder Coating Equipment LineUS$ 2000 - 40000MOQ: 1 Set

-

High Efficiency Automatic PVC Dip Mold Machine for Small Caps (200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Small Plastisol PVC Cap Molding Machine (Automatic, 200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Automatic PVC Dip Coating Machine for 8mm×14mm Small CapsUS$ 2000 - 40000MOQ: 1 Set

-

Greenhouse Wiggle Wire Making Machine, Pvc-coated Wiggle Wire MachineUS$ 2000 - 40000MOQ: 1 Set

-

PVC Plastisol Production Equipment, Used to Produce Pvc Plastisol LiquidUS$ 2000 - 40000MOQ: 1 Set

-

Precision-Engineered PVC Plastisol Production Equipment Machine, Mixing TanksUS$ 2000 - 40000MOQ: 1 Set

-

Liquid PVC Plastisol Mixing Equipment MachinesUS$ 2000 - 40000MOQ: 1 Set

-

Thermal Flame Spraying Machine for Thermoplastic PowderUS$ 1000 - 5000MOQ: 1 Set

-

Thermoplastic Powder Fire Flame Spraying Coating Equipment for Metal PartsUS$ 1000 - 5000MOQ: 1 Set