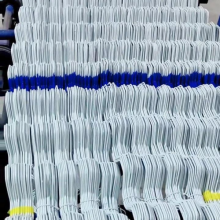

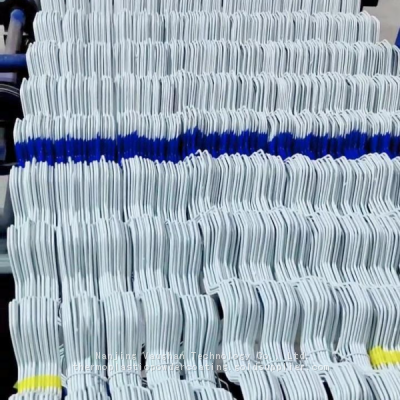

PVC PE-Coated Zigzag Wiggle Wire Making Machine Line, Greenhouse Spring Wire Production Equipment

As a core equipment for greenhouse accessory production, the Greenhouse PVC PE-Coated Zigzag Wiggle Wire Making Machine Line from us has won global recognition for its high automation, stable performance, and efficient output. Designed specifically to manufacture PE-coated zigzag wiggle wires—key components for securing plastic films in greenhouses—this production line integrates multiple processes to meet the diverse needs of greenhouse construction enterprises worldwide.

Core Advantages: Automation, Stability, and Efficiency

The Greenhouse PVC PE-Coated Zigzag Wiggle Wire Making Machine Line stands out with three core strengths that redefine production standards. First, it features full automation, covering every step from steel wire feeding to finished product packing. Advanced systems handle bending, forming, PE powder coating, mark point processing, counting, and bundling in an orderly manner, minimizing manual intervention and ensuring consistent product quality.

Second, it operates with exceptional stability. Strict control over structural design and component selection enables the line to run continuously under high-intensity conditions with minimal failures or unexpected downtime, a critical factor for maintaining steady production schedules.

Third, it delivers impressive efficiency. With an output capacity of 25 pieces per minute (1,500 pieces per hour), the line significantly boosts productivity. It also saves labor costs: one worker can operate a single line, and skilled operators can manage up to three sets simultaneously. The line occupies a floor area of L 15.6m × W 5.5m × H 3.2m and requires 25Kw of power, making it suitable for most factory layouts.

Technical Specifications and Customization

The Greenhouse PVC PE-Coated Zigzag Wiggle Wire Making Machine Line offers flexible customization to adapt to different production requirements. In terms of product specifications, it can produce wiggle wires with diameters of 2.0mm, 2.3mm, or any other customer-specified diameter. For length, common options include 1.86m, 1.96m, and 2.05m—note that the buyer must confirm the specific length before production, as it requires corresponding adjustments to bending and forming molds. By default, the line is configured for one length; additional lengths incur extra charges.

Mark points are another customizable feature. The line is designed with 4 mark points as standard, but more can be added based on customer needs. For raw materials, it works with carbon steel wire and spring steel wire (both galvanized and non-galvanized). While galvanized wire slightly reduces coating adhesion due to its zinc layer, the PE coating still provides a second layer of protection, making galvanized PE-coated wires a popular choice. The recommended steel grade is No. 55, as No. 65 steel is harder and more difficult to process.

Workflow and Post-Purchase Support

The workflow of the Greenhouse PVC PE-Coated Zigzag Wiggle Wire Making Machine Line is streamlined for precision and speed. It starts with steel wire laying and straightening, followed by bending and forming to create the zigzag shape. Next, the wire undergoes alignment correction and electrical heating before PE powder coating. After coating curing, leveling, and cooling, flame heating is used to apply powder coating to mark points, which then go through another curing and cooling cycle. Finally, the finished wires are automatically counted, bundled, and packed—ready for shipment.

Post-purchase support ensures a smooth user experience. The line comes with a 1-year warranty, covering free replacement of non-artificially damaged parts (excluding consumables). Beyond the warranty, technical services and part replacements are still available, with the buyer covering part and transportation costs. The line has a service life of at least 10 years under optimal conditions.

Why Choose This Production Line?

This Greenhouse PVC PE-Coated Zigzag Wiggle Wire Making Machine Line is a reliable investment for enterprises in the greenhouse accessory industry. Its high automation reduces labor and error rates, stable performance ensures long-term productivity, and flexible customization meets diverse market demands.

Send Inquiry to This Supplier

You May Also Like

-

Food-Safe LDPE Powder Coating for Metal Baskets and Shelves, Superior Corrosion Resistance in Commercial RefrigeratorsUS$ 2 - 3MOQ: 1000 Kilograms

-

Customizable Color Thermoplastic Dip LDPE Powder Coating, Enhances Durability for Household Refrigerator ComponentsUS$ 2 - 3MOQ: 1000 Kilograms

-

Fluidized Bed Dip LDPE Powder Coating for Refrigerator Grids, Operating Range -40°C to 80°C, Hygienic SurfaceUS$ 2 - 3MOQ: 1000 Kilograms

-

REACH/RoHS Compliant Thermoplastic Dip LDPE Powder Coating - Food Grade Protection for Refrigerator Shelves, Grids and Storage BasketsUS$ 2 - 3MOQ: 1000 Kilograms

-

Battery Boxes Use Thermoplastic PE Polyethylene Powder Coating Black RAL9005 High Anti-CorrosionUS$ 2 - 3MOQ: 1000 Kilograms

-

Thermoplastic PE Polyethylene Powder Coating for Battery Containers,Gray RAL7016 Low-Temperature ResistantUS$ 2 - 3MOQ: 1000 Kilograms

-

Industrial Battery Boxes Use High-Strength Thermoplastic PE Polyethylene Powder CoatingUS$ 2 - 3MOQ: 1000 Kilograms

-

Acid & Alkali Resistant Thermoplastic PE Polyethylene Powder Coating for New Energy Vehicle Battery BoxesUS$ 2 - 3MOQ: 1000 Kilograms

-

Battery Storage Boxes Use Thermoplastic PE Polyethylene Powder Coating, High-Gloss (60° Gloss 70%)US$ 2 - 3MOQ: 1000 Kilograms

-

Thermoplastic PVC Polyethylene Coating for Electroplating Racks Jigs Fixture,High-Temperature Resistant & Chemical-ProofUS$ 2 - 3MOQ: 1000 Kilograms