As a dedicated manufacturer since 2018, Nanjing Vaughn Tech Co. Ltd. proudly presents our advanced Dip Mould Machine, designed to revolutionize your production with reliable technical support and complimentary maintenance. Operating from a modern 5,000-10,000 square meter facility in Nanjing, China, we leverage over five years of expertise to deliver high-quality industrial solutions that enhance efficiency and reduce operational costs. With an annual export value of US$2.5 Million to US$5 Million and a team of 11-50 skilled professionals, our machines are engineered for precision and durability, backed by rigorous certifications like ISO9001 and ISO14000. This commitment ensures you receive a product that not only meets global standards but also provides exceptional value through its innovative features and comprehensive after-sales service.

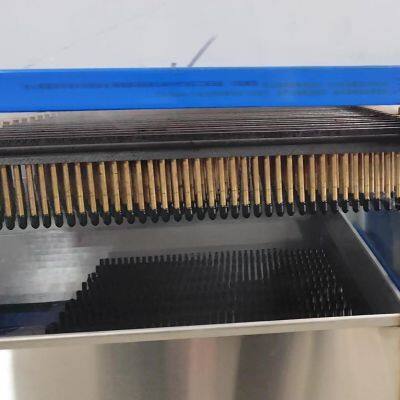

Our Dip Mould Machine excels in delivering consistent, high-quality results for various industrial applications, such as coating electronic components, automotive parts, and consumer goods. Key features include:

- Automated Precision: Equipped with a programmable logic controller (PLC) system, the machine ensures accurate dipping depths and timing, minimizing human error and maximizing output consistency.

- Durable Construction: Built with stainless steel components, it resists corrosion and wear, extending the machine's lifespan even in harsh environments.

- Energy Efficiency: Optimized power consumption reduces electricity costs by up to 20% compared to conventional models, contributing to sustainable operations.

- User-Friendly Interface: Featuring an intuitive touchscreen panel, operators can easily adjust settings like temperature and dipping speed, reducing training time.

- Versatile Applications: Suitable for dipping plastics, rubbers, and metals, it adapts to diverse industries including electronics, automotive, and packaging.

Technical specifications are detailed in the table below, showcasing the machine's adaptability and performance. These parameters ensure seamless integration into your production line, offering benefits such as reduced waste, faster cycle times, and improved product quality.

| Parameter | Value |

|---|---|

| Power Supply | 220V/380V, 50Hz |

| Max Dipping Capacity | Up to 100 kg/hour |

| Temperature Range | 50°C to 200°C (adjustable) |

| Dimensions (LxWxH) | Customizable upon request |

| Control System | PLC-based automation |

| Material Compatibility | Plastics, rubbers, metals |

Clients benefit from reduced downtime and lower maintenance costs due to the machine's robust design and included free service plan. For instance, the automated diagnostics alert operators to potential issues before they escalate, ensuring continuous operation. Additionally, the customizable sizing allows for tailored solutions, whether for small-batch prototyping or high-volume production, making it a versatile asset for businesses aiming to scale efficiently.

Trust in Nanjing Vaughn Tech's proven track record: with a global footprint serving markets across North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, and the Domestic Market, our machines are shipped from major ports like Shanghai, Ningbo, Tianjin, and Qingdao. Supported by multiple certifications including HACCP, TL900, QS9000, SA8000, ISO9001, ISO9004, ISO17799, ISO9000, ISO14000, ISO10441, ISO16949, TS16969, ISO19011:2000, OHSAS18001, and others, this Dip Mould Machine guarantees reliability and compliance. Invest in a solution that combines cutting-edge technology with unwavering support—contact us today for a personalized consultation and experience how our machine can elevate your production efficiency while saving costs.

Frequently Asked Questions (FAQ):

-

Q: What does the free maintenance include?

A: Our free maintenance covers regular check-ups, lubrication, and minor part replacements for one year post-purchase, ensuring optimal performance without extra charges. -

Q: How is technical support provided for this machine?

A: Technical support is available via phone, email, or video call, with on-site assistance optional for complex issues; our team responds within 24 hours. -

Q: Can the machine handle different dipping materials?

A: Yes, it's compatible with various materials like PVC, latex, and silicone; specific settings can be customized upon request. -

Q: What certifications ensure product quality?

A: The machine meets standards like ISO9001 and ISO14000, with full documentation available; other certifications are listed in our product manual. -

Q: Is operator training included with purchase?

A: Basic training is provided through manuals and online resources; comprehensive on-site training is available upon request. -

Q: How long is the delivery time for international orders?

A: Delivery typically takes 4-6 weeks, depending on destination; we ship from ports like Shanghai and Ningbo for efficiency. -

Q: Can I customize the machine's dimensions?

A: Absolutely, dimensions and capacities are customizable; share your requirements, and we'll tailor a solution. -

Q: What is the warranty period?

A: A standard one-year warranty covers manufacturing defects, extendable with optional service plans.

Send Inquiry to This Supplier

You May Also Like

-

PVC PE-Coated Zigzag Wiggle Wire Making Machine Line, Greenhouse Spring Wire Production EquipmentUS$ 2000 - 40000MOQ: 1 Set

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Dip Mould Machine For PVC Plastisol Caps Sleeves Cover RootsUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Dip PVC Plastisol Coating Equipment Line For Metal Handles RacksUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Fluidized Bed Dip Powder Coating Equipment LineUS$ 2000 - 40000MOQ: 1 Set

-

High Efficiency Automatic PVC Dip Mold Machine for Small Caps (200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Small Plastisol PVC Cap Molding Machine (Automatic, 200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Automatic PVC Dip Coating Machine for 8mm×14mm Small CapsUS$ 2000 - 40000MOQ: 1 Set

-

Greenhouse Wiggle Wire Making Machine, Pvc-coated Wiggle Wire MachineUS$ 2000 - 40000MOQ: 1 Set

-

PVC Plastisol Production Equipment, Used to Produce Pvc Plastisol LiquidUS$ 2000 - 40000MOQ: 1 Set