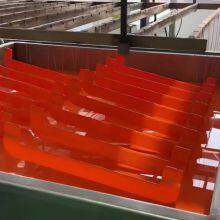

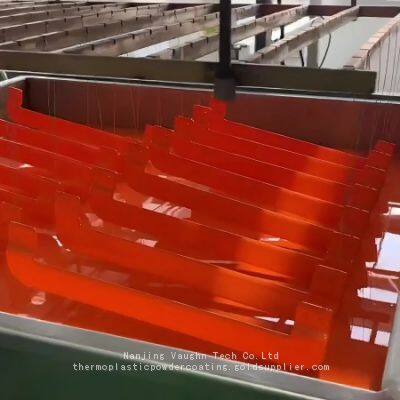

As a trusted manufacturer since 2018, Nanjing Vaughn Tech Co.Ltd proudly introduces our premium PVC Dip Coating Equipment, designed to deliver exceptional performance with a robust 1-year warranty and dedicated tech support. Operating from our 5,000-10,000 square meter facility in Nanjing, China, we leverage advanced manufacturing capabilities to produce reliable solutions for global markets, including North America, Europe, and Asia. With annual exports valued at US$2.5 Million - US$5 Million, we ensure consistent quality and innovation, backed by certifications like ISO 9001 and ISO 14000. This equipment is engineered to streamline your coating processes, reducing downtime and enhancing productivity for diverse industrial applications.

Our PVC Dip Coating Equipment stands out for its efficiency and versatility. Key features include:

High Precision Coating: Achieves uniform PVC layers with adjustable thickness control, minimizing waste and ensuring consistent results.

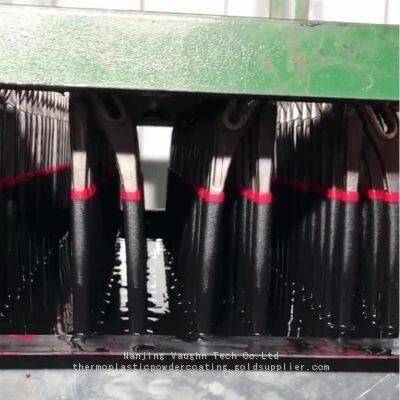

Automated Operation: Features user-friendly controls for easy setup, reducing labor costs and human error.

Energy Efficiency: Incorporates low-power consumption systems, cutting operational expenses by up to 20% compared to conventional models.

Durable Build: Constructed with high-grade steel for long-lasting performance in harsh industrial environments.

Customizable Configurations: Adaptable to specific production needs, such as varying tank sizes or coating speeds.

Technical specifications highlight the equipment's adaptability and reliability. Below is a summary of key parameters:

| Parameter | Value |

|---|---|

| Coating Thickness Range | 0.1-2.0 mm (customizable) |

| Heating Temperature | 50-200°C (adjustable) |

| Processing Speed | 1-5 meters per minute |

| Power Requirement | 220-440V, 50/60Hz |

| Dimensions (LxWxH) | Customizable upon request |

Clients benefit from reduced material costs, faster production cycles, and improved product durability. For instance, the automated system allows for 24/7 operation with minimal supervision, ideal for high-volume manufacturing. Additionally, the included tech support ensures quick troubleshooting, maximizing uptime and ROI.

Backed by our extensive certifications including HACCP, OHSAS18001, and ISO 16949, Nanjing Vaughn Tech guarantees compliance and safety across all operations. Serving diverse markets from Eastern Europe to Oceania, we ship efficiently from ports like Shanghai and Ningbo, ensuring timely delivery. With a team of 11-50 skilled professionals, we provide personalized service and post-sale assistance. Invest in our PVC Dip Coating Equipment today to elevate your coating quality and efficiency—contact us for a tailored quote and discover how our solutions can transform your production line.

Frequently Asked Questions (FAQ):

Q: What is PVC dip coating used for?

A: PVC dip coating applies a protective layer to metal or plastic parts, commonly in automotive, electronics, and construction industries for corrosion resistance.Q: What does the 1-year warranty include?

A: It covers manufacturing defects and component failures, with repair or replacement services provided at no extra cost.Q: How is technical support delivered?

A: Support is available via phone, email, or remote assistance, with optional on-site visits for complex issues.Q: Can the equipment handle different PVC formulations?

A: Yes, it's designed to accommodate various PVC types, with settings adjustable for optimal performance.Q: What certifications apply to this product?

A: It meets standards like ISO 9001 and ISO 14000, ensuring quality and environmental compliance.Q: Is customization available for specific needs?

A: Absolutely, we offer tailored solutions for tank size, speed, and other parameters upon request.Q: What are the shipping options and timelines?

A: We ship from ports including Tianjin and Qingdao, with delivery typically taking 4-6 weeks depending on destination.Q: How does this equipment improve efficiency?

A: Automation reduces labor, while precise controls minimize material waste, boosting overall productivity by up to 30%.

Send Inquiry to This Supplier

You May Also Like

-

Dip Mould Machine With Technical Support and Free MaintenanceNegotiableMOQ: 1 Set

-

Automatic Dip Mould Machine With PLC Control for Precision CoatingNegotiableMOQ: 1 Set

-

Customizable Dip Mould Machine for Textile and Fabric CoatingNegotiableMOQ: 1 Set

-

Stainless Steel Dip Mould Machine for Industrial Rubber MoldingNegotiableMOQ: 1 Set

-

Dip Mould Machine With Temperature Control for Polymer ApplicationsNegotiableMOQ: 1 Set

-

High-Speed Dip Mould Machine for Ceramic and Glass CoatingNegotiableMOQ: 1 Set

-

PVC PE-Coated Zigzag Wiggle Wire Making Machine Line, Greenhouse Spring Wire Production EquipmentUS$ 2000 - 40000MOQ: 1 Set

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Dip Mould Machine For PVC Plastisol Caps Sleeves Cover RootsUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Dip PVC Plastisol Coating Equipment Line For Metal Handles RacksUS$ 2000 - 40000MOQ: 1 Set