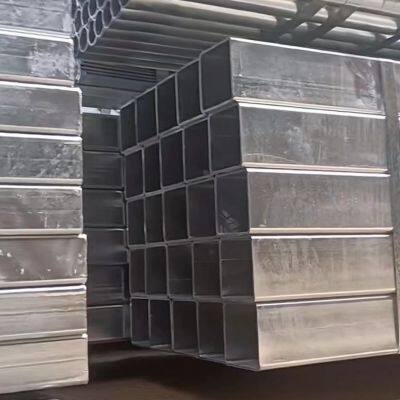

Hot-dip Galvanized Square Tubes

I. Product Definition

Hot-dip galvanized square pipes are metal tubes formed by anti-corrosion treatment of low-carbon steel or low-alloy steel square-section steel pipes through the hot-dip galvanizing process. Their core structure is a rectangular hollow section (equal sides for square pipes, unequal sides for rectangular pipes, collectively referred to as rectangular square pipes). Through the metallurgical reaction between the substrate and molten zinc liquid, a zinc-iron alloy protective layer is formed, combining the structural stability of square pipes with the excellent anti-corrosion performance of hot-dip galvanizing. They are core load-bearing and protective materials in machinery manufacturing, construction engineering, infrastructure construction, and other fields.

II. Production Process Principles

1. Substrate Pretreatment: Low-carbon steel/low-alloy steel strips of Q215, Q235, Q345 series are selected, and black square pipes (un-galvanized pipes) are made through slitting, forming, and high-frequency welding. The welded joints are annealed online to ensure uniform structural strength.

2. Surface Purification: Black square pipes undergo alkali washing and degreasing (removing oil stains) → acid pickling and rust removal (removing oxide scales with hydrochloric acid/sulfuric acid solution) → water washing and neutralization (clearing residual acid solution) → flux treatment (immersing in ammonium chloride-zinc chloride mixed solution to improve coating adhesion). The pH value and temperature are controlled throughout to avoid secondary corrosion of the substrate.

3. Hot-Dip Galvanizing: The pretreated square pipes are immersed in molten zinc at 445-465℃ for 3-8 minutes (adjusted according to pipe diameter). A metallurgical reaction occurs between the steel pipe substrate and the zinc liquid, sequentially forming three alloy layers: FeZn₇ (Γ phase), Fe₅Zn₂₁ (δ₁ phase), and FeZn₁₃ (ζ phase), with a pure zinc layer (η phase) covering the outer layer, ensuring uniform and controllable total coating thickness.

4. Post-Treatment Processes: After galvanizing, the pipes are cooled, passivated (improving zinc layer weather resistance) → straightened (ensuring verticality and dimensional accuracy of square pipes) → cut to length (fixed length or custom cutting) → inspected (appearance, size, coating thickness, mechanical performance testing) → packaged and warehoused.

III. Key Technical Parameters

1. Specifications (mm)

Regular Side Length Range Corresponding Wall Thickness Range Length Specifications Special Customization

20×20 - 50×50 1.2 - 3.0 6m/unit (fixed length) Side length ≤ 300×300mm, wall thickness ≤ 12mm

60×60 - 100×100 2.0 - 5.0 9m/unit (customized) Length can be cut as required (minimum 1m)

120×120 - 200×200 3.0 - 8.0 12m/unit (engineering grade) Special-shaped square pipes (e.g., rounded square pipes) can be produced

2. Material & Mechanical Properties

• Base Material Grades: Q215A/B, Q235A/B/C, Q345A/B/C, Q450NQR1 (weathering steel)

• Tensile Strength: ≥335MPa (Q235 grade), ≥470MPa (Q345 grade)

• Yield Strength: ≥235MPa (Q235 grade), ≥345MPa (Q345 grade)

• Elongation After Fracture: ≥21% (all grades)

• Flattening Test: When flattened to 1/3 of the side length, no cracks in the welds and no peeling of the zinc layer

• Hydrostatic Test: Test pressure ≥2.5MPa, no leakage after 30 minutes of pressure retention

3. Zinc Coating Quality Standards (Compliant with GB/T 13912-2022)

• Coating Thickness: Average thickness ≥65μm (corresponding to zinc coating weight ≥460g/㎡), minimum local thickness ≥55μm

• Adhesion: No blistering or peeling of the zinc layer after 180° cold bending test (bending radius = 6×wall thickness); no zinc layer peeling after hammer test (1kg hammer dropped from 300mm height)

• Uniformity: No red copper layer precipitation after 6 consecutive immersions in copper sulfate solution (1 minute per immersion)

• Surface Quality: Uniform and bright coating, no uncoated areas, black spots, bubbles, or cracks; slight zinc nodules and scratches (depth ≤0.3mm) are allowed

IV. Core Product Advantages

1. Excellent Corrosion Resistance & Durability: The dual protection of zinc-iron alloy layer and pure zinc layer can isolate air, moisture, and soil electrolyte corrosion. The service life can reach 25-30 years in outdoor natural environments and ≥15 years in industrial environments, which is 5-8 times that of ordinary painted square pipes, with no frequent maintenance or replacement needed.

2. Strong Structural Load-Bearing Capacity: The square pipe cross-section has a large moment of inertia, with better bending, torsion, and compression resistance than round pipes of the same material. The hot-dip galvanizing process does not damage the mechanical properties of the substrate, and the coating at the welded joints is fully covered, ensuring overall structural stability. It can be directly used for core load-bearing frames, support columns, and other key parts.

3. Firm Coating with No Easy Peeling: The metallurgical bonding mode integrates the zinc layer with the steel pipe substrate, with adhesion far superior to electro-galvanizing (cold galvanizing) and spraying processes. It can withstand collisions, friction during transportation and installation, as well as vibration and deformation during long-term use, without the risk of coating peeling leading to corrosion.

4. Full-Surface Protection Without Dead Ends: Molten zinc liquid can fully penetrate into key areas such as the inner wall, edges, and welds of square pipes. The zinc layer thickness at the edges is consistent with that of the flat surface (traditional spraying processes often have missing or thin coating at edges), completely solving the "edge corrosion" problem and achieving uniform anti-corrosion on the entire surface.

5. High Cost-Effectiveness: Although the initial procurement cost is higher than that of ordinary black square pipes, no additional anti-corrosion maintenance is required during long-term use. The comprehensive life cycle cost is only 1/3-1/2 of that of painted square pipes, and it has high recycling value, conforming to the development trend of green building materials (long-term, energy-saving, and environmentally friendly).

6. Environmentally Friendly & Compliant: The production process complies with national standards GB/T 3091-2015 "Welded Steel Pipes for Low-Pressure Fluid Transportation", GB/T 13912-2022 "Technical Requirements for Hot-Dip Galvanizing", and has no heavy metal pollution. It replaces high-pollution cold galvanized square pipes and can pass environmental protection testing and certification.

V. Executive Standards

• National Standards: GB/T 3091-2015 (low-pressure fluid transportation), GB/T 13912-2022 (hot-dip galvanizing layer technical requirements), GB/T 6728-2017 (cold-formed hollow sections for structures)

• Industry Standards: JGJ 255-2012 (anti-corrosion technical standards for building steel structures), SY/T 0413-2002 (anti-corrosion layer technical standards for oil and gas pipelines)

• International Standards: ASTM A500 (American standard for structural square and rectangular pipes), EN 10219 (European standard for cold-formed hollow sections), BS EN ISO 1461 (international standard for hot-dip galvanizing)

VI. Application Fields

1. Construction Engineering: Steel structure frame columns, beams, support components; curtain wall keels, door and window frame skeletons; balcony railings, stair handrails; roof supports, skylight structures; temporary building scaffolding, prefabricated house frames.

2. Infrastructure: Municipal road guardrails, isolation fences; bridge guardrails, pier supports; urban pipeline brackets, communication tower frames; anti-corrosion components for ports and terminals, storage shelf columns.

3. Machinery Manufacturing: Equipment frames, workbench frames; agricultural machinery (harvesters, greenhouse frames); construction machinery (excavators, cranes) structural parts; automated production line conveying tracks.

4. Fluid Transportation: Low-pressure water supply and drainage pipes, fire protection pipes; corrosion-resistant pipes for the chemical industry (neutral media); agricultural irrigation pipes, aquaculture pond water supply and drainage pipes.

5. Other Fields: Automotive manufacturing (auxiliary frame structures); photovoltaic brackets, wind turbine auxiliary components; billboard frames, lamp pole supports; anti-corrosion components for offshore engineering near the sea (additional anti-corrosion treatment required).

Send Inquiry to This Supplier

You May Also Like

-

Hot-dip Galvanized Steel PipeNegotiableMOQ: 5 Metric Tons

-

Steel Pipe & TubeNegotiableMOQ: 10 Pieces

-

Steel RebarNegotiableMOQ: 5 Metric Tons

-

Steel WireNegotiableMOQ: 5 Kilograms

-

insulated PipeNegotiableMOQ: 5 Metric Tons

-

Steel AngleNegotiableMOQ: 5 Metric Tons

-

Insulated Steel PipeNegotiableMOQ: 5 Metric Tons

-

Insulated Steel PipeNegotiableMOQ: 5 Metric Tons

-

Steel WireNegotiableMOQ: 5 Kilograms

-

Galvanized Iron Wire- Material: SAE1008 / Q195NegotiableMOQ: 5 Kilograms