Hpmc Insights & Buyer's Guide

HPMC, also known as hypromellose, is classified under the category of cellulose ethers, which belong to the class of highly versatile products. Cellulose-based chemical compound, including HPMC, is known for their use in applications where tailor-made viscosity, solvent systems, and water retention are required. This polymer is produced by altering the native cellulose and thus forms a compound with varied properties like gelling, film forming, and stabilizing. The structure of HPMC is such that it forms gels and solutions in water; hence, it is used in drug formulations as an excipient, construction chemicals such as mortar or tile adhesive as an additive. In addition to that, because it serves as a water-soluble stabilizer and thickener, different products cannot be made without it.

The most significant aspect of HPMC is the degree of substitution; that is, the number (mean) of hydroxyl groups present on cellulose that were substituted with hydroxypropyl and methyl groups per anhydroglucopyranose unit. The degree of substitution and the molecular weight result in different solubility and viscosity parameters of hPMC in aqueous media, thus dampening the performance of the material in some geometries. There are many different kinds of HPMC present that permit such control, in one case, for instance, pharmacology, medicine allowing for sustained release dosage forms, or in the other case, construction, increasing the workability of ready-to-use mortars. Equally, HPMC should be frequently used with high temperatures as it improves the extent of weathering, and is non-toxic, hence can be used for many purposes. Looking at HPMC even further, as particle size and mole concentration must be considered before embarking on emulsifying activities in a formula, the above factors as well will be covered.

Definition and Overview of HPMC

What is Hydroxypropyl Methylcellulose?

HPMC, also known as hydroxypropyl methylcellulose, is an altered cellulose ether derived from natural cellulose, which is the most common organic compound in nature and is an important component of the cell walls of plants. In the course of modification, the hydroxyl groups of cellulose are replaced by hydroxypropyl and methyl groups on the cellulose skeleton to form a water-soluble polymer that has found use in various fields owing to its wide range of properties. It’s highly sought after in many applications because of its gelling, thickening, and suspending characteristics. With its thin-body visar viscous and water-binding properties, the problem-solving polymer is not too challenging to manufacture. formulate. HPMC is a very useful adjunct in tablet and capsule manufacture in the pharmaceutical industry, where it serves as a resin or suppressant that can regulate the release of drugs. In addition to the applications in plumbing, tile, and mortar adhesives improve due to the presence of this cellulose polymer. HPMC is a cellulose-based compound used in the thickening and stabilization of appropriate products.

Chemical Structure and Properties of HPMC

The hydroxypropyl methylcellulose substituent amount defines the average hydroxyl groups extent replaced by hydroxypropyl and methyl groups. This phenomenon affects the capability of solubility and viscosity of HPMC, enabling different unique options for its application. HPMC chain length is important to the polymer’s physical characteristics, including whether it gels and how well it holds water, properties that are heavily influenced by the chain’s molecular weight. It is also worth noting that HPMC, on the other hand, retains its stability even at higher temperatures, which is a feature that enables its application in hot spots. HPMC is synthesized in different grades to meet various industrial requirements, making it possible to be used as a thickener, emulsifier, and stabilizer among other numerous applications. The polymer is, nevertheless, soluble in water and thus very useful in different areas of application such as pharmacy and construction.

Different Types of Cellulose Ethers

Methylcellulose (MC), hydroxypropyl methylcellulose (HPMC), hydroxyethyl cellulose (HEC), hydroxypropyl cellulose (HPC), carboxymethyl cellulose (CMC), and ethyl cellulose (EC) – there are several types of cellulose ethers.

Cellulose ethers – prepared from cellulose initiate versatility in terms of per below major aspects.

MC – Food Additive (thickener/binder).

HPMC – It is mainly used in in pharmacy construction and, cosmetics industry.

HEC – Paints, adhesives, drilling muds – these are the most prominent examples.

HPC – In the form of tablets, adhesives, and coatings.

Carboxy Methyl Cellulose – This is widely used as it helps in thickening as well as in food products.

Ethyl Cellulose – Most commonly, this type of ether is used in various coatings and as an anti-moisture agent.

Such examples illustrate meeting operational requirements of various industries by tailoring cellulose derivatives in terms of solubilities, stabilities, or availabilities of functions.

Applications of HPMC

HPMC in Pharmaceuticals: Tablets and Capsules

In the formulation of tablets and capsules in the pharmaceutical industry, Hydroxypropyl Methylcellulose (HPMC) is a critical substance as an excipient. Characteristically, its high viscosity and water retention make it suitable for employment in controlled drug release systems. Cellulose ether HPMC is employed as it forms the gel and is water soluble, in the industry for the preparation of solid dosage forms. Polymer solubility promotes the use of methyl propyl ethyl cellulose with modified cellulose filled with methyl and hydroxy propyl groups as a binder and film former in compressed ingredients. Various HPMC product grades exist for the specific purpose of modifying the viscosity and maintaining, or controlling, rates of dissolution for specific drugs. The performance of HPMC also varies with the level of substitution, as this is what stabilizes the ingredients and suspends them for longer periods, hence improving bioavailability. This polymer technique offers ease of manufacture and patient compliance because the tablets and capsules are designed to incorporate their active ingredient in water-soluble plastic, allowing for proper therapy.

Use of HPMC as a Food Additive

The use of Hydroxypropylmethylcellulose (HPMC) is widespread in the food industry because of its ability to thicken, emulsify, and stabilize food systems. HPMC is significant in food formulation as it is one such food enhancer that modifies the texture and helps in food preservation. These functional properties enable its use in application areas such as Bakery products, Dairy, sauces, etc., where gels and aqueous solutions of HPMC are employed as thickening and stabilizing agents. Being water soluble, HPMC has a higher advantage of being easily added into food compositions and also causes no change from the initial intended viscosity-forming during consumption. As a result, practitioners of low-fat or gluten-free health trends may incorporate HPMC into food fatty formulations as a good fake traditional, firm texture. Also, the thermal potential of the fiber derivative makes its use more preferable in food processing, with a guarantee that the required viscosity will be intact at every stage, including consumption.

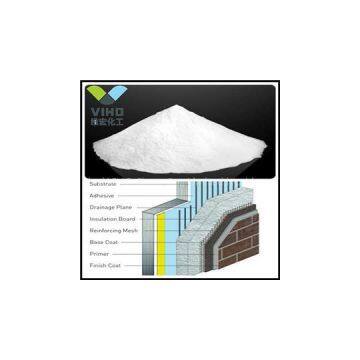

Role of HPMC in Construction: Wall Putty and Coatings

In the building industry, wall putty, coatings are some of the products for which hydroxypropyl methylcellulose (HPMC) is used as an important additive. This is because most construction materials require these agents as thickeners and stabilizers so that they can improve their work efficiency and output. The ability of the HPMC to hold onto water is one of the most beneficial features that enhances the usage of wall putty by ensuring that it does not crack upon application. Under the influence of this polymer’s thick, highly viscous, and water-soluble nature, coatings form a stable, non-breaking adhesive layer that enhances the attachment of coatings to the surfaces underneath. In addition to HPMC, a binder, HPMC improves how easy it is to apply the tile adhesives and also increases the time during which the interface can be worked upon, making tile alignment and positioning by adhesive adjustment much easier. Various forms of HPMC tend to be advantageous to the extent that it is employed in manufacturing, where the product can vary from one construction need to the next. On top of these, HPMC experiences no degradation even upon exposure to a hot environment; thus, the materials used in construction are still usable and functional regardless of varying climatic changes.

Benefits and Properties of HPMC

Viscosity and Solubility Characteristics

The wide range of uses of Hydroxypropyl Methylcellulose (HPMC) owes significantly to its very distinct viscosity and solubility characteristics. Being a kind of cellulose ether, HPMC is very characteristic of forming viscous solutions when it comes into contact with water, its degree of substitution singleness embedded in its molecular structure. Due to these functionalities, it is used on multiple occasions as it serves as a thickener or stabilizer, or emulsifier in several formulations. HPMC's presence in water was a composed chaos, that infinite, thus crystalline solutions devoid of any impurities can be formed, which is imperative in pharmaceutical and food production industries. Unfortunately, this is not the case, as explained, that solubility is very temperature dependent and extremely relies on how many hydroxypropyl and methyl groups it has incorporated, so different viscosity and solubility limits can be designed for use in HPMC. HPMC, as a gelling substance, can be added to tablets and capsules for a prolonged release of an active agent, and can also be used for product stabilization in the food and construction industries.

Thickening and Stabilizing Properties

Among the various advantages of using Hydroxypropyl Methylcellulose (HPMC), its thickening and stabilizing functions are the most prominent, allowing better performance of some products. If HPMC as a thickener is used, the thickening of some compounds will not affect their stability; the pharmaceutical industry and to construction industry prefer its utilization. The sector that utilizes pharmaceutical applications utilizes HPMC in the modulation of the composition of tablets and capsules in order to facilitate controlled trends in the release of the active ingredient. However, when it comes to the construction scope, its presence in the composition of such products as tile adhesive or wall putty thickener provides the manageable workability and maximum adhesion of the materials. What is more, HPMC also plays the stabilizing role, in the sense that it prevents separation of the particles within the suspension or any product, in that they keep the entire product more or less of the same thickness or consistency. In particular, this is especially useful for food and personal care products where emulsion and dispersion stability an important components of product quality. HPMC is used widely as a thickener and a stabilizer in many applications owing to its unique aggregating and long-acting abilities, which enable distinctiveness and reliability in various types of products.

Advantages of Using HPMC in Various Applications

Due to its numerous advantages, whenever it is used, Hydroxypropyl Methylcellulose (HPMC) becomes an industrial additive that is indeed hard to neglect. A primary advantage of HPMC is its ability to improve the product by increasing viscosity, water retention, and stabilization. When it comes to medicines, such an agent as HPMC is used in making tablets and capsules and other solid doses for the purpose of regulating the release of drugs and so that the active substances can be administered correctly. This capacity is especially useful in cases where medication must remain active for extended periods of time, as it forms a gel framework with the drug substance, the drug being released slowly over time. It has been observed that the use of HPMC in mortars as well as in tile adhesives, thanks to its advantageous application in the construction sector, radically increases workability and adhesion of the mortars, hence creating stable and functional construction products. In addition to that, it aids in the food industry purposes as a stabilizer, especially in low-fat and gluten-free food, as emulsifiers, thickeners, and gelling agents, among many other functions. The ability of the HPMC to meet the EPA requirements across various categories includes enhancing the quality of a product as well as its development.

Frequently Asked Questions (FAQs)

What is the role of hydroxypropyl methylcellulose?

Hydroxypropyl methylcellulose is a water-binding cellulose derivative, more specifically a cellulose ether. This additive stabilizes the textures and improves the characteristics of products produced, which makes it useful in numerous applications without exception. It is edible and does not smell - thus it can come in several food products, drugs, and also building substances. Such physical shapes of HPMC as in terms of its thickness, solubility, can also be an issue, although that is determined by the type and the amount of HPMC. HPMC products are manufactured to satisfy several different uses for a specific process or system.

In what ways is HPMC effectively applied in pharmacy?

In the pharmacy of any kind, HPMC takes a very important part as it is the tablet or capsule formation agent that plays a role in binding and stabilizing. Also, in some cases, by enhancing the solubility or the availability of the active constituent, HPMC enhances the formulation. In addition, HPMC is an ingredient during the preparation of elements for controlled release, thus prolonging the administration of drugs. Different grades of the compound HPMC have been manufactured such that they permit various formulations in one dosage form, depending on the requirements for the profile or viscosity properties needed. As if that is not enough, the application of the substance geometrically extends as it is used in making gels and emulsifiers.

How can HPMC be applied in the construction industry?

The use of HPMC in the construction industry cannot be overemphasized. It is used as a component of wall putty, tile adhesives, and cementaceous composites. In such formulations, it contributes to the thickening and retention of water for the purpose of improving the effect of the material. Additionally, these cellulose ethers are very useful in controlling water loss, which is essential for retardation in modes of handling and curing of construction materials. It has been apparent that the usage of beneficial substances, such as HPMC, helps create a smooth surface and thus enhances the final product quality. There are many instances where building products requires specific formulas; hence, some manufacturers offer different HPMC products.

What role does HPMC play in the food industry?

There are a few food additives that include HPMC, which is a thickening, emulsifying, and stabilizing agent and is used in numerous types of foods. In particular, the fact that it is tasteless makes it a favourite for enhancing texture and consistency in foods without any additives or calories. More specifically, the usage of HPMC spans over food categories such as sauces, dressings, and bakery items. It is soluble in water, thus making formulation easy, and with its relevant physicochemical characteristics, it is also appropriate for use during manufacturing and storage. HPMC also carries out the function of keeping the food extravagant and palatable for a long time, which is why it is relatively reliable in the food industry.

What are the functions of HPMC concerning different types of HPMC and their applications?

The viscosity of different grades of HPMC could change the way it behaves when used for a certain application. HPMC grades with the highest viscosity are usually preferred where thickening is needed, whereas for applications that involve flow or dispersion, low viscosity grades are preferred. Nevertheless, the substitution levels of HPMC once again came in handy for understanding the water solubility of these formulations as well as the rheological behavior of these solutions. Manufacturers can adjust the degree of substitution to produce HPMC suitable for a certain formulation. It is of utmost importance to know the characteristics of each HPMC grade, as this helps one choose the desired HPMC grade with regard to the application so as to obtain the best performance and output.

Constructional HpmcNegotiableMOQ: 1 TonPlace of Origin: Shandong, ChinaClassification: Other AdhesivesMain Raw Material: Other, building material additiveUsage: Construction, Other, Construction, Coating Auxiliary AgentsShandong Xindadi Industrial Group Co., Ltd.5 Yrs

Constructional HpmcNegotiableMOQ: 1 TonPlace of Origin: Shandong, ChinaClassification: Other AdhesivesMain Raw Material: Other, building material additiveUsage: Construction, Other, Construction, Coating Auxiliary AgentsShandong Xindadi Industrial Group Co., Ltd.5 Yrs HpmcUS$ 1 - 2MOQ: 1 TonBrand Name: ASENCELPlace of Origin: ChinaUsage: ConstructionMain Raw Material: Other, Hydroxypropyl methyl celluloseShijiazhuang Henggu Jianxin Cellulose Co.,Ltd

HpmcUS$ 1 - 2MOQ: 1 TonBrand Name: ASENCELPlace of Origin: ChinaUsage: ConstructionMain Raw Material: Other, Hydroxypropyl methyl celluloseShijiazhuang Henggu Jianxin Cellulose Co.,Ltd Hpmc With High Purity and Strength Increasing for Gypsum EIFS Dry Mix MortarNegotiableMOQ: 500 KilogramsPlace of Origin: ChinaType: AdsorbentUsage: Coating Auxiliary Agents, Textile Auxiliary Agents, Water Treatment ChemicalsAdsorbent Variety: Molecular SieveHebei Jingzuan Chemical Technology Co., Ltd

Hpmc With High Purity and Strength Increasing for Gypsum EIFS Dry Mix MortarNegotiableMOQ: 500 KilogramsPlace of Origin: ChinaType: AdsorbentUsage: Coating Auxiliary Agents, Textile Auxiliary Agents, Water Treatment ChemicalsAdsorbent Variety: Molecular SieveHebei Jingzuan Chemical Technology Co., Ltd Hpmc - Rheology Agent - HpmcUS$ 2000 - 5000MOQ: 1 TonBrand Name: QUALICELLPlace of Origin: ChinaType: CONSTRUCTION GRADEOther Names: MHPCAnxin Cellulose Co.,Ltd

Hpmc - Rheology Agent - HpmcUS$ 2000 - 5000MOQ: 1 TonBrand Name: QUALICELLPlace of Origin: ChinaType: CONSTRUCTION GRADEOther Names: MHPCAnxin Cellulose Co.,Ltd High Purity Hpmc 200000 Construction Grade Hydroxypropyl Methyl Cellulose HpmcNegotiableMOQ: 5 Metric TonsBrand Name: sunaPlace of Origin: ChinaType: Carbon BlackPurity: 99%Hebei Suna Technology Co., Ltd.

High Purity Hpmc 200000 Construction Grade Hydroxypropyl Methyl Cellulose HpmcNegotiableMOQ: 5 Metric TonsBrand Name: sunaPlace of Origin: ChinaType: Carbon BlackPurity: 99%Hebei Suna Technology Co., Ltd. Hydroxypropyl Methyl Cellulose HpmcUS$ 1.7 - 2.3MOQ: 1 TonType: Other, Cellulose etherUsage: Coating Auxiliary Agents, Textile Auxiliary AgentsShandong Tenessy Chemical Co.,Ltd.

Hydroxypropyl Methyl Cellulose HpmcUS$ 1.7 - 2.3MOQ: 1 TonType: Other, Cellulose etherUsage: Coating Auxiliary Agents, Textile Auxiliary AgentsShandong Tenessy Chemical Co.,Ltd. Hpmc Hydroxypropyl Methyl Cellulose LEAD TA60HUS$ 2100 - 2200MOQ: 1 TonBrand Name: LEADPlace of Origin: ChinaModel Number: TA60HType: Other, admixtureHebei Yida Cellulose Co., Ltd.

Hpmc Hydroxypropyl Methyl Cellulose LEAD TA60HUS$ 2100 - 2200MOQ: 1 TonBrand Name: LEADPlace of Origin: ChinaModel Number: TA60HType: Other, admixtureHebei Yida Cellulose Co., Ltd. Hpmc for Self Leveling MortarNegotiableMOQ: 1 Metric TonType: Other, hpmcUsage: Coating Auxiliary AgentsJinan Maissen New Material Co., Ltd.

Hpmc for Self Leveling MortarNegotiableMOQ: 1 Metric TonType: Other, hpmcUsage: Coating Auxiliary AgentsJinan Maissen New Material Co., Ltd. Hpmc CAS9004-65-3US$ 2.8 - 2.85MOQ: 1 KilogramBrand Name: JianfengPlace of Origin: ChinaModel Number: JF-15wType: Other, Water Retention AgentsJinzhou City Jianfeng Building Materials Co., Ltd

Hpmc CAS9004-65-3US$ 2.8 - 2.85MOQ: 1 KilogramBrand Name: JianfengPlace of Origin: ChinaModel Number: JF-15wType: Other, Water Retention AgentsJinzhou City Jianfeng Building Materials Co., Ltd Hydroxypropyl Methyl Cellulose Ether(Hpmc) Hot Selling for Dry Mortar and Tile AdhesiveUS$ 2800 - 3300MOQ: 2 TonsBrand Name: ViganerPlace of Origin: ChinaType: Other, polymerHenan Xinbaoneng Sci&Tech Development Co., Ltd

Hydroxypropyl Methyl Cellulose Ether(Hpmc) Hot Selling for Dry Mortar and Tile AdhesiveUS$ 2800 - 3300MOQ: 2 TonsBrand Name: ViganerPlace of Origin: ChinaType: Other, polymerHenan Xinbaoneng Sci&Tech Development Co., Ltd Self Level Mortar Uses Hpmc LK400NegotiableMOQ: 1 Short TonLongou International Business Shanghai Co., Ltd

Self Level Mortar Uses Hpmc LK400NegotiableMOQ: 1 Short TonLongou International Business Shanghai Co., Ltd MK200P High-Viscosity Hpmc for Tile Adhesives With Excellent Slip ResistanceNegotiableMOQ: 1000 KilogramsCAS No.: 9004-65-3Color: WhiteAppearance: PowderUsage: Coating Auxiliary Agents, Other, thickener for adhesiveShandong Meikai Chemical Technology Co., Ltd.

MK200P High-Viscosity Hpmc for Tile Adhesives With Excellent Slip ResistanceNegotiableMOQ: 1000 KilogramsCAS No.: 9004-65-3Color: WhiteAppearance: PowderUsage: Coating Auxiliary Agents, Other, thickener for adhesiveShandong Meikai Chemical Technology Co., Ltd. Popular Good Workability Thickening Agent Hpmc Concrete Admixture Used in Cement Based Skim Coat HpmcUS$ 1680 - 1682MOQ: 5 Metric TonsPlace of Origin: ChinaClassification: Other AdhesivesUsage: Construction, Footwear & LeatherMain Raw Material: AcrylicHebei Suna Technology Co., Ltd.

Popular Good Workability Thickening Agent Hpmc Concrete Admixture Used in Cement Based Skim Coat HpmcUS$ 1680 - 1682MOQ: 5 Metric TonsPlace of Origin: ChinaClassification: Other AdhesivesUsage: Construction, Footwear & LeatherMain Raw Material: AcrylicHebei Suna Technology Co., Ltd. Hpmc Powder 200000 Cps Hydroxypropyl Methyl Cellulose for Tile Adhesive Cement Mortar Hpmc PriceNegotiableMOQ: 1 Short TonBrand Name: JINGMENGModel Number: HPMCState: Powder CoatingCAS No.: 9004-65-3Jinzhou Jingmeng Chemical Technology Co., LTD

Hpmc Powder 200000 Cps Hydroxypropyl Methyl Cellulose for Tile Adhesive Cement Mortar Hpmc PriceNegotiableMOQ: 1 Short TonBrand Name: JINGMENGModel Number: HPMCState: Powder CoatingCAS No.: 9004-65-3Jinzhou Jingmeng Chemical Technology Co., LTD Hpmc(hydroxypropyl Methyl Cellulose)US$ 2000 - 2800MOQ: 1 Metric TonBrand Name: bangshangPlace of Origin: ChinaType: Other, thickening agentMF: C12H20O10Bangshang International Co.,ltd / Bangshang Chemicals

Hpmc(hydroxypropyl Methyl Cellulose)US$ 2000 - 2800MOQ: 1 Metric TonBrand Name: bangshangPlace of Origin: ChinaType: Other, thickening agentMF: C12H20O10Bangshang International Co.,ltd / Bangshang Chemicals GENEX Hpmc CapsuleUS$ 0.01 - 0.02MOQ: 3000000 PiecesBrand Name: GENEXPlace of Origin: ChinaModel Number: 201704181Shaanxi Genex Bio-Tech Co.,Ltd

GENEX Hpmc CapsuleUS$ 0.01 - 0.02MOQ: 3000000 PiecesBrand Name: GENEXPlace of Origin: ChinaModel Number: 201704181Shaanxi Genex Bio-Tech Co.,Ltd Hydroxypropyl Methyl Cellulose(Hpmc)NegotiableMOQ: 1 TonBrand Name: KIMACELLPlace of Origin: ChinaState: Powder CoatingCAS No.: 9004-65-3Kima Chemical Co.,ltd

Hydroxypropyl Methyl Cellulose(Hpmc)NegotiableMOQ: 1 TonBrand Name: KIMACELLPlace of Origin: ChinaState: Powder CoatingCAS No.: 9004-65-3Kima Chemical Co.,ltd Hydroxypropyl Methyl Cellulose (Hpmc) for Construction Mortar/ for Tile AdhesiveUS$ 2000 - 2500MOQ: 1 TonBrand Name: BangshangPlace of Origin: ChinaEINECS No.: 220-971-6MF: C12H20O10Bangshang International Co.,Ltd.

Hydroxypropyl Methyl Cellulose (Hpmc) for Construction Mortar/ for Tile AdhesiveUS$ 2000 - 2500MOQ: 1 TonBrand Name: BangshangPlace of Origin: ChinaEINECS No.: 220-971-6MF: C12H20O10Bangshang International Co.,Ltd. Hydroxypropyl Cellulose Hpmc Chemical Auxiliary Agent Fiona@crovellbio.com Whatsapp +86 19930503281US$ 1 - 1MOQ: 1 KilogramUsage: Cosmetic Raw MaterialsHebei Guanlang

Hydroxypropyl Cellulose Hpmc Chemical Auxiliary Agent Fiona@crovellbio.com Whatsapp +86 19930503281US$ 1 - 1MOQ: 1 KilogramUsage: Cosmetic Raw MaterialsHebei Guanlang Hpmc for Tile Adhesive | Strong Bond & Anti-Slip | C1 & C2 ApplicationsNegotiableMOQ: 1000 KilogramsTransport Package: bagSpecification: 25kg/bagTrademark: Landercoll®Origin: ChinaShandong Landu New Material Co.,Ltd

Hpmc for Tile Adhesive | Strong Bond & Anti-Slip | C1 & C2 ApplicationsNegotiableMOQ: 1000 KilogramsTransport Package: bagSpecification: 25kg/bagTrademark: Landercoll®Origin: ChinaShandong Landu New Material Co.,Ltd Hydroxypropyl Methyl Cellulose Ether Hpmc 200000US$ 2 - 3MOQ: 5 TonsBrand Name: viganerPlace of Origin: ChinaModel Number: VN-5200Application: Self-leveling,Tile adhesive,Joint filler,Putty ,Insulation system,General mortar,Light-weight mortar , Industry paintsHenan Xinbaoneng Sci&Tech Development Co.,Ltd

Hydroxypropyl Methyl Cellulose Ether Hpmc 200000US$ 2 - 3MOQ: 5 TonsBrand Name: viganerPlace of Origin: ChinaModel Number: VN-5200Application: Self-leveling,Tile adhesive,Joint filler,Putty ,Insulation system,General mortar,Light-weight mortar , Industry paintsHenan Xinbaoneng Sci&Tech Development Co.,Ltd Factory Supply Ceramic Grade HydroxyPropyl Methyl Cellulose HpmcUS$ 1350 - 1400MOQ: 5 TonsBrand Name: -Place of Origin: ChinaModel Number: -Type: Other, white powderHebei Suna Technology Co., Ltd

Factory Supply Ceramic Grade HydroxyPropyl Methyl Cellulose HpmcUS$ 1350 - 1400MOQ: 5 TonsBrand Name: -Place of Origin: ChinaModel Number: -Type: Other, white powderHebei Suna Technology Co., Ltd HpmcUS$ 3.8 - 3.8MOQ: 1 KilogramBrand Name: qianrunPlace of Origin: ChinaShijiazhuang Ziqian Import And Export Co,LTD

HpmcUS$ 3.8 - 3.8MOQ: 1 KilogramBrand Name: qianrunPlace of Origin: ChinaShijiazhuang Ziqian Import And Export Co,LTD Buyer submitted an RFQ for printed empty hpmc/vegetable/vegetarian Capsules2025-12-08 02:03:34

Buyer submitted an RFQ for printed empty hpmc/vegetable/vegetarian Capsules2025-12-08 02:03:34 Procurement Specialist submitted an RFQ for Hydroxypropyl Methyl Cellulose (HPMC/MHPC)2025-12-06 11:17:09

Procurement Specialist submitted an RFQ for Hydroxypropyl Methyl Cellulose (HPMC/MHPC)2025-12-06 11:17:09 Purchaser placed an order for Cellulose Ethers for Ceramic Tile Adhesive14 hours ago

Purchaser placed an order for Cellulose Ethers for Ceramic Tile Adhesive14 hours ago Import Coordinator requested a quote for hydroxypropyl methyl cellulose (HPMC)2025-12-06 01:43:39

Import Coordinator requested a quote for hydroxypropyl methyl cellulose (HPMC)2025-12-06 01:43:39 Sourcing Agent requested specs for Mortar Additive hydroxypropyl Starch/hpmc Ether RDP2025-12-04 20:31:40

Sourcing Agent requested specs for Mortar Additive hydroxypropyl Starch/hpmc Ether RDP2025-12-04 20:31:40 Purchaser requested a quote for Thickener Sodium Carboxymethyl Cellulose CMC/HPMC Food Grade for Ice Cream2025-12-04 13:03:45

Purchaser requested a quote for Thickener Sodium Carboxymethyl Cellulose CMC/HPMC Food Grade for Ice Cream2025-12-04 13:03:45 Procurement Lead placed an order for New Building Construction Materials HPMC2025-12-09 03:44:29

Procurement Lead placed an order for New Building Construction Materials HPMC2025-12-09 03:44:29 Importer is sourcing Vegetable Empty Capsules (HPMC)2025-12-05 13:06:15

Importer is sourcing Vegetable Empty Capsules (HPMC)2025-12-05 13:06:15 Sourcing Agent requested specs for HPMC (Hydroxypropyl Methyl Cellulose)2025-12-05 11:03:31

Sourcing Agent requested specs for HPMC (Hydroxypropyl Methyl Cellulose)2025-12-05 11:03:31 Hpmc Empty Capsule Pullulan Empty Capsule Starch Empty Capsule Liquid-filled Capsule Acid-resistant Capsule Delayed Release CapsuleUS$ 0.003 - 0.00369MOQ: 1000 PiecesBrand Name: jiuzhou capsulePlace of Origin: ChinaModel Number: 000#,00#,0#,1#,2#,3#Jiuzhou Capsule Bio-Pharmaceuticals (Guangzhou) Co., Ltd

Hpmc Empty Capsule Pullulan Empty Capsule Starch Empty Capsule Liquid-filled Capsule Acid-resistant Capsule Delayed Release CapsuleUS$ 0.003 - 0.00369MOQ: 1000 PiecesBrand Name: jiuzhou capsulePlace of Origin: ChinaModel Number: 000#,00#,0#,1#,2#,3#Jiuzhou Capsule Bio-Pharmaceuticals (Guangzhou) Co., Ltd VISC ( Hpmc )US$ 2 - 2MOQ: 1000 PiecesBrand Name: D-ViscoPlace of Origin: ChinaModel Number: D-viscoAadpri Ophthalmic Company

VISC ( Hpmc )US$ 2 - 2MOQ: 1000 PiecesBrand Name: D-ViscoPlace of Origin: ChinaModel Number: D-viscoAadpri Ophthalmic Company Modified HpmcNegotiableMOQ: 1 SetPlace of Origin: ChinaModel Number: Modified HPMCKimix Chemical Co.,Ltd.

Modified HpmcNegotiableMOQ: 1 SetPlace of Origin: ChinaModel Number: Modified HPMCKimix Chemical Co.,Ltd. Hpmc RenderUS$ 4200 - 4200MOQ: 5 KilogramsBrand Name: aobangPlace of Origin: ChinaModel Number: HY200000Aobang Imp&Exp Co.,ltd

Hpmc RenderUS$ 4200 - 4200MOQ: 5 KilogramsBrand Name: aobangPlace of Origin: ChinaModel Number: HY200000Aobang Imp&Exp Co.,ltd