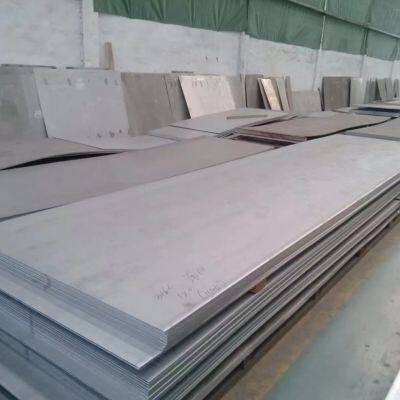

Carbon structural steel plates (mild steel plates) are basic steel plates mainly composed of iron and carbon, with no or a small amount of alloying elements added. Featuring simple production process, low cost and excellent processability, they are the most widely used general-purpose steel plates in industrial production, suitable for processing structural and basic components with no special performance requirements.

1. Core Definition & Key Properties

- Definition: Hot-rolled or cold-rolled steel plates that comply with carbon structural steel standards, with a carbon content of 0.06%~0.22% and a total alloying element content of ≤3%. Classified into rimmed steel, killed steel and semi-killed steel, killed steel (e.g., Q235B) is the most widely applied.

- Key Properties:

- Basic mechanical performance: Moderate yield and tensile strength, meeting the stress requirements of conventional structures.

- Excellent processability: Superb cold bending, shearing, welding and stamping performance, enabling forming without complex processes.

- High cost performance: Mature production process with a price much lower than alloy steel plates and stainless steel plates.

- Wide applicability: Suitable for all working conditions without special requirements for high temperature resistance, severe corrosion resistance or high wear resistance.

2. Common Grades & Executive Standards

Main National Standard Grades

- Q235 Series (Q235A/Q235B/Q235C/Q235D): The core grade is Q235B with a yield strength of ≥235MPa, the most commonly used grade for carbon structural steel plates, applicable to most general scenarios.

- Q195/Q215: Lower yield strength and softer material, suitable for processing thin and light components and stamped parts.

- Q255/Q275: Slightly higher strength, used for lightly stressed structural parts and mechanical accessories.

Executive Standards

- Hot-rolled carbon structural steel plates: GB/T 3274-2024 (Hot-rolled steel plates and strips of carbon structural steels and low alloy structural steels).

- Cold-rolled carbon structural steel plates: GB/T 708-2019 (Dimensions, shape, weight and tolerance for cold-rolled steel plates and strips).

3. Common Specifications & Delivery Conditions

Conventional Specifications

- Hot-rolled plates: Thickness 3mm~200mm, width 1000mm~3800mm, with customizable fixed lengths.

- Cold-rolled plates: Thickness 0.3mm~6mm, featuring a smoother surface and higher precision, suitable for precision small parts.

Delivery Conditions

- Hot-rolled plates: Delivered in hot-rolled state with black surface/pickled surface, can be directly processed or subject to subsequent derusting and painting.

- Cold-rolled plates: Delivered in cold-rolled state with a smooth and clean surface, ready for use without additional treatment.

4. Main Application Scenarios

As the "basic steel plate" of industry, carbon structural steel plates are used in construction, machinery, light industry, logistics and other fields, with typical applications including:

- Construction engineering: Steel structure beams and columns, floor slabs, scaffolding, embedded parts, fence guardrails.

- Mechanical manufacturing: General mechanical bases, supports, cabinets, non-core transmission accessories.

- Light industry and home appliances: Furniture frames, shelves, distribution boxes, shells of simple equipment.

- Logistics and packaging: Pallets, container fittings, metal packing cases, transportation supports.

- Hardware processing: Basic hardware such as embedded parts, stamped parts, sheared parts and welded parts.

5. Key Points for Selection & Application

1. Select grades on demand: Prioritize Q235B for general structures, Q195/Q215 for thin and light stamped parts, and Q255/Q275 for lightly stressed components.

2. Confirm delivery conditions: Choose cold-rolled plates for high surface precision requirements, and hot-rolled plates for thick plates and large structural parts.

3. Match processing techniques: Carbon structural steel plates have excellent weldability and can be welded with ordinary welding electrodes, with no risk of cracking during cold bending.

4. Anti-corrosion treatment: Carbon structural steel plates have no corrosion resistance; anti-corrosion treatments such as painting and galvanizing are required for outdoor use to prevent rusting.

5. Acceptance criteria: Inspect dimensional deviation and surface quality in accordance with national standards, ensuring no defects such as cracks, scabs and folds.

Send Inquiry to This Supplier

You May Also Like

-

Steel Pipe & TubeNegotiableMOQ: 10 Metric Tons

-

Steel WireNegotiableMOQ: 5 Metric Tons

-

Steel Coil & StripNegotiableMOQ: 5 Metric Tons

-

Ship PlateNegotiableMOQ: 5 Metric Tons

-

Hot-dip Galvanized Square TubesNegotiableMOQ: 5 Metric Tons

-

Carbon Steel PipeNegotiableMOQ: 5 Metric Tons

-

Vessel PlateNegotiableMOQ: 5 Metric Tons

-

Alloy Steel PlateNegotiableMOQ: 5 Metric Tons