Steel Angle

1. By side width ratio

- Equal angle steel: Two sides with equal width, marked as: Width × Width × Thickness, e.g. 50×50×5.

- Unequal angle steel: Two sides with different widths, marked as: Long side × Short side × Thickness, e.g. 63×40×5.

2. By surface treatment

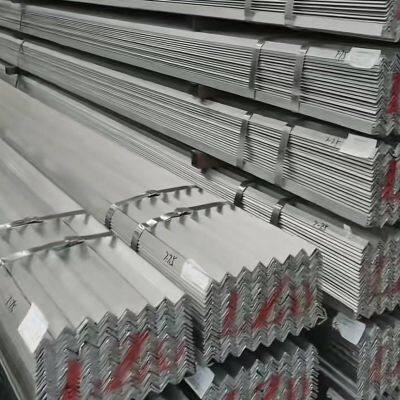

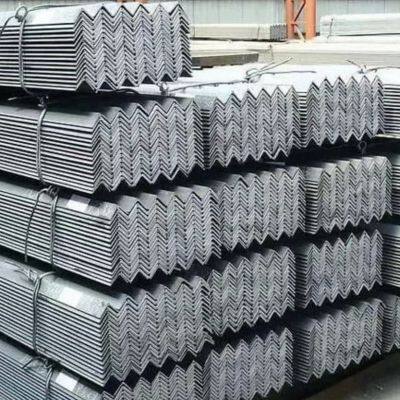

- Black angle steel (hot-rolled black finish): Untreated surface, low cost, suitable for indoor structures or applications with general anti-corrosion requirements.

- Hot-dip galvanized angle steel: With strong anti-corrosion and anti-rust performance, suitable for outdoor use, power towers, municipal engineering, coastal and high-corrosion environments.

3. By production process

- Hot-rolled angle steel (mainstream, high strength, complete specifications)

- Cold-formed angle steel (thin wall, small size, customized non-standard products)

2. Common Materials & Application Standards

Common Materials

- Q235B (most widely used for general structures)

- Q355B (high-strength low-alloy steel, replacing 16Mn)

- S235JR, S355JR (European standard for export)

- A36, A572 (American standard)

Execution Standards

- Chinese Standard: GB/T 706, GB/T 1591

- European Standard: EN 10025

- American Standard: ASTM A36 / A572

3. Specification Description

- Equal angle steel: L × b × b × t (L=length, b=side width, t=thickness)

Example: L50×50×5 × 6000mm

- Unequal angle steel: L × B × b × t (B=long side, b=short side)

Example: L63×40×5 × 6000mm

Standard lengths: 6m, 9m, 12m; customized cutting available.

4. Product Features & Performance

1. Excellent section mechanical properties, high bending, shear and compression resistance, stable structural performance.

2. Good workability for welding, drilling, cutting, bending and bolting.

3. Complete specifications, covering small decorative supports to large tower structures.

4. Hot-dip galvanized angle steel provides long anti-corrosion life and reduces maintenance cost for outdoor use.

5. Easy installation and strong universality, compatible with various steel structure systems.

6. Stable supply and high cost performance, widely used as mainstream structural section steel in industrial and construction projects.

5. Main Application Fields

- Building steel structures: workshops, warehouses, stadiums, supports, frames

- Power & communication: transmission towers, telecommunication towers, substation structures

- Curtain wall engineering: keels, main and secondary frames, connectors

- Pipeline engineering: pipe supports, pipe corridors, hangers

- Machinery manufacturing: equipment bases, frames, protective structures

- Bridges & municipal engineering: guardrails, supports, reinforcing members

- Ships, mines, storage shelves, photovoltaic brackets, etc.

6. Quality Control

Products are manufactured in strict accordance with national standards, with full-process inspection covering raw materials, rolling, straightening, cutting, surface quality, dimensional tolerance and mechanical properties. Galvanized products comply with hot-dip galvanizing coating thickness requirements. Material certificates, inspection reports and commodity inspection documents for import and export can be provided.

Send Inquiry to This Supplier

You May Also Like

-

Steel Pipe & TubeNegotiableMOQ: 10 Metric Tons

-

Steel WireNegotiableMOQ: 5 Metric Tons

-

Steel Coil & StripNegotiableMOQ: 5 Metric Tons

-

Ship PlateNegotiableMOQ: 5 Metric Tons

-

Hot-dip Galvanized Square TubesNegotiableMOQ: 5 Metric Tons

-

Carbon Steel PipeNegotiableMOQ: 5 Metric Tons

-

Vessel PlateNegotiableMOQ: 5 Metric Tons

-

Alloy Steel PlateNegotiableMOQ: 5 Metric Tons

-

Mild Steel PlateNegotiableMOQ: 5 Metric Tons

-

Steel RebarNegotiableMOQ: 5 Metric Tons